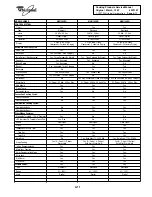

4-2

Model MH9115XE

BK = Black

BR = Brown

RD = Red

YL = Yellow

GN = Green

BL = Blue

PK = Pink

WH = White

NOTES:

1. Oven is Off.

2. Door is Open.

CAVITY

THERMAL

PROTECTOR

MAGNETRON

THERMAL

PROTECTOR

BK

BK

BK

L

GN

N

W

W

15A LINE

FUSE

BK

RELAY #2

RELAY #1

LOW-VOLTAGE

TRANSFORMER

1

2

RELAY #3

RELAY #4

RELAY #5

RELAY #6

8

3

4

5

6

7

PRIMARY

INTERLOCK

SWITCH

COOKTOP LIGHTS

RD

W

RD

W

OVEN LIGHT

W

BL

(C)

(NC)

(NO)

BK

BL

BR

YL

YL

W

W

BR

BASE

THERMAL

PROTECTOR

W

PK

RD

BL

YL

BK

(LOW)

(HI)

(C)

YL

RD

BLOWER

MOTOR

FAN

MOTOR

TURNTABLE

MOTOR

BL

MONITOR

SWITCH

SECONDARY

INTERLOCK

SWITCH

BR

RD

W

W

(C)

(NO)

(C)

(NC)

BL

BL

RD

RD

PK

BK

HIGH-VOLTAGE

TRANSFORMER

HIGH-VOLTAGE

CAPACITOR

RECTIFIER

BL

BR

PK

BL

TEMP

PROBE

RD

W

RD

W

RD

FA

F

MAGNETRON

PK

RD

BL

BR

YL

BK

W

PK

BL

BR

PK

BL

1

2

3

4

5

6

7

8

1

2

3

4

1

2

3

8-PIN CONNECTOR

4-PIN CONNECTOR

3-PIN CONNECTOR

CONTROL MODULE

1

2

3

4

MICROCOMPUTER

BOARD

Summary of Contents for 1997 "E"

Page 40: ...2 30 NOTES ...