11

Understanding Sounds You

May Hear

Your new ice maker may make sounds that are not familiar

to you. Because the sounds are new to you, you might be

concerned about them. Most of the new sounds are

normal. Hard surfaces like the floor, walls and cabinets can

make the sounds seem louder than they actually are. The

following describes the kinds of sounds that might be new

to you and what may be making them.

■

You will hear a buzzing sound when the water valve

opens to fill the water reservoir for each cycle.

■

Rattling noises may come from the flow of the

refrigerant or the water line. Items stored on top of the

ice maker can also make noises.

■

The high efficiency compressor may make a pulsating

or high pitched sound.

■

Water running over the evaporator plate may make a

splashing sound.

■

Water running from the evaporator plate to the water

reservoir may make a splashing sound.

■

As each cycle ends, you may hear a gurgling sound

due to the refrigerant flowing in your ice maker.

■

You may hear air being forced over the condenser by

the condenser fan.

■

During the harvest cycle, you may hear a “thud” when

the ice sheet slides from the evaporator onto the cutter

grid.

■

When you first start the ice maker, you may hear water

running continuously. The ice maker is programmed to

run a rinse cycle before it begins to make ice.

USING YOUR

ICE MAKER

Understanding How Your Ice

Maker Works

When you first start your ice maker, the water pan will fill

and the system will rinse itself before starting to make ice.

The rinsing process takes about five minutes.

Under normal operating conditions, the ice maker will

cycle at preset temperatures. The ice level sensor located

in the ice storage bin will monitor the ice levels.

IMPORTANT

■

If the water supply to the ice maker is turned off, be

sure to set the ice maker control to OFF.

■

The ice maker is designed to make clear ice from the

majority of water sources on a daily basis. If your

results are unsatisfactory, your water may need to be

filtered or treated.

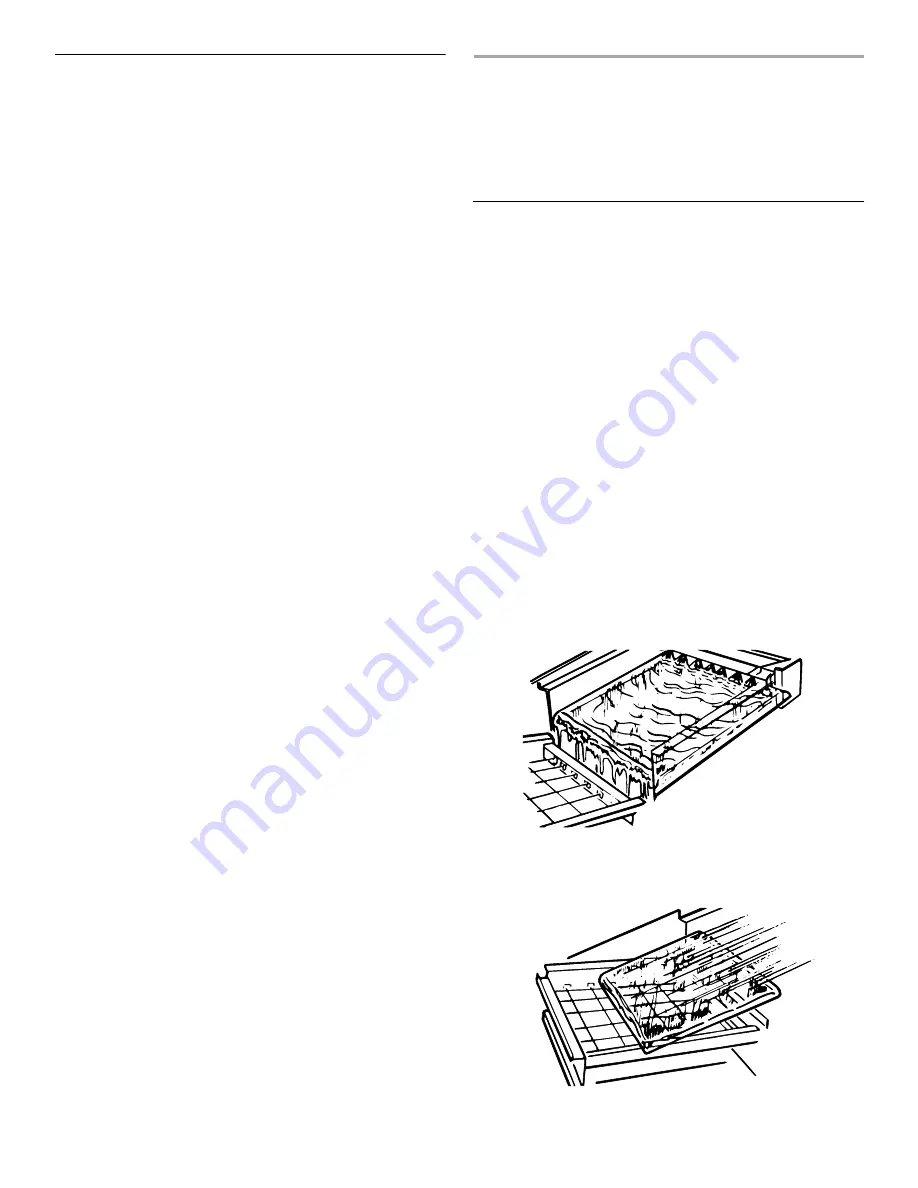

Making Ice

1. Water is constantly circulated over a freezing plate. As

the water freezes into ice, the minerals in the water are

rejected. This produces a clear sheet of ice with a low

mineral content.

2. When the desired thickness is reached, the ice sheet is

released and slides onto a cutter grid. The grid divides

the sheet into individual cubes.