2

VENTING DESIGN SPECIFICATIONS

This section is intended for architectural designer and builder/contractor reference only.

NOTES:

■

Vent materials needed for installation are not provided with

microwave hood.

■

We do not recommend using a flexible metal vent.

■

To avoid possible product damage, be sure to vent air outside,

unless using ventless (recirculating) installation. Do not vent

exhaust air into concealed spaces, such as spaces within

walls or ceilings, attics, crawl spaces or garages.

For optimal venting installation, we recommend:

■

using roof or wall caps that have back draft dampers

■

using a rigid metal vent

■

using the most direct route by minimizing the length of the

vent and number of elbows to provide efficient performance

■

using uniformly sized vents

■

using duct tape to seal all joints in the vent system

■

using caulking compound to seal exterior wall or roof opening

around cap

■

not installing 2 elbows together, for optimal hood performance

If venting through the wall, be sure that there is proper clearance

within the wall for the damper to open fully.

If venting through the roof, and rectangular to round transition is

used, be sure there is at least 3" (7.6 cm) of clearance between

the top of the microwave oven and the transition piece. See

“Rectangular to Round Transition” illustration.

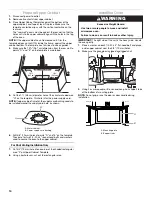

Rectangular to Round Transition

NOTE: The minimum 3" (7.6 cm) clearance must exist between

the top of the microwave oven and the rectangular to round

transition piece so that the damper can open freely and fully.

Recommended Standard Fittings

The following length equivalents are for use when figuring vent

length. See the examples in “Recommended Vent Length.”

Roof venting

Roof cap

Wall venting

Wall cap

A. Roof cap

B. 6" (15.2 cm) min. diameter round vent

C. Elbow (for wall venting only)

D. Wall cap

E. 3

¹⁄₄

" x 10" to 6" (8.3 x 25.4 cm to 15.2 cm)

rectangular to round transition piece

F. Vent extension piece, at least 3" (7.6 cm) high

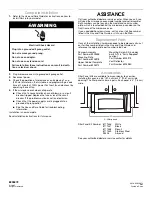

A. Rectangular to round transition piece: 3

¹⁄₄

" x 10" to 6" = 5 ft

(8.3 x 25.4 cm to 15.2 cm = 1.5 m)

B. Roof cap: 3

¹⁄₄

" x 10" = 24 ft (8.3 x 25.4 cm = 7.3 m)

C. 90° elbow: 3

¹₄

" x 10" = 25 ft (8.3 x 25.4 cm = 7.6 m)

D. 90° elbow: 6" = 10 ft (15.2 cm = 3 m)

E. Wall cap: 3

¹⁄₄

" x 10" = 40 ft (8.3 x 25.4 cm = 12.2 m)

F. 45° elbow: 6" = 5 ft (15.2 cm = 1.5 m)

G. 90° flat elbow: 3

¹⁄₄

" x 10" = 10 ft (8.3 x 25.4 cm = 3 m)

A

B

C

E

F

D

3" (7.6 cm)

A B C

D E F G