6

Natural Gas:

This dryer is equipped for use with

NATURAL GAS. It is design-certified

by CSA International for L.P. (propane

or butane) gases with appropriate

conversion.

L.P. Gas:

No attempt shall be made to convert

the appliance from the gas specified

on the model/serial rating plate for use

with a different gas without consulting

the serving gas supplier.

Conversion must be done by a

qualified service technician. Gas

conversion kit part numbers are

listed on the gas valve burner base.

Burner input requirements:

Elevations up to 10,000 feet:

The design of this dryer has been

certified by CSA International for use

at altitudes up to 10,000 feet above

sea level at the B.T.U. rating indicated

on the model/serial rating plate. Burner

input adjustments are not required

when the dryer is operated up to this

elevation.

Elevations above 10,000 feet:

When installed above 10,000 feet, a

four percent (4%) reduction of the

burner B.T.U. rating shown on the

model/serial rating plate is required for

each 1,000 foot increase in elevation.

For assistance installing dryer above

10,000 feet elevation, contact your

serving gas supplier.

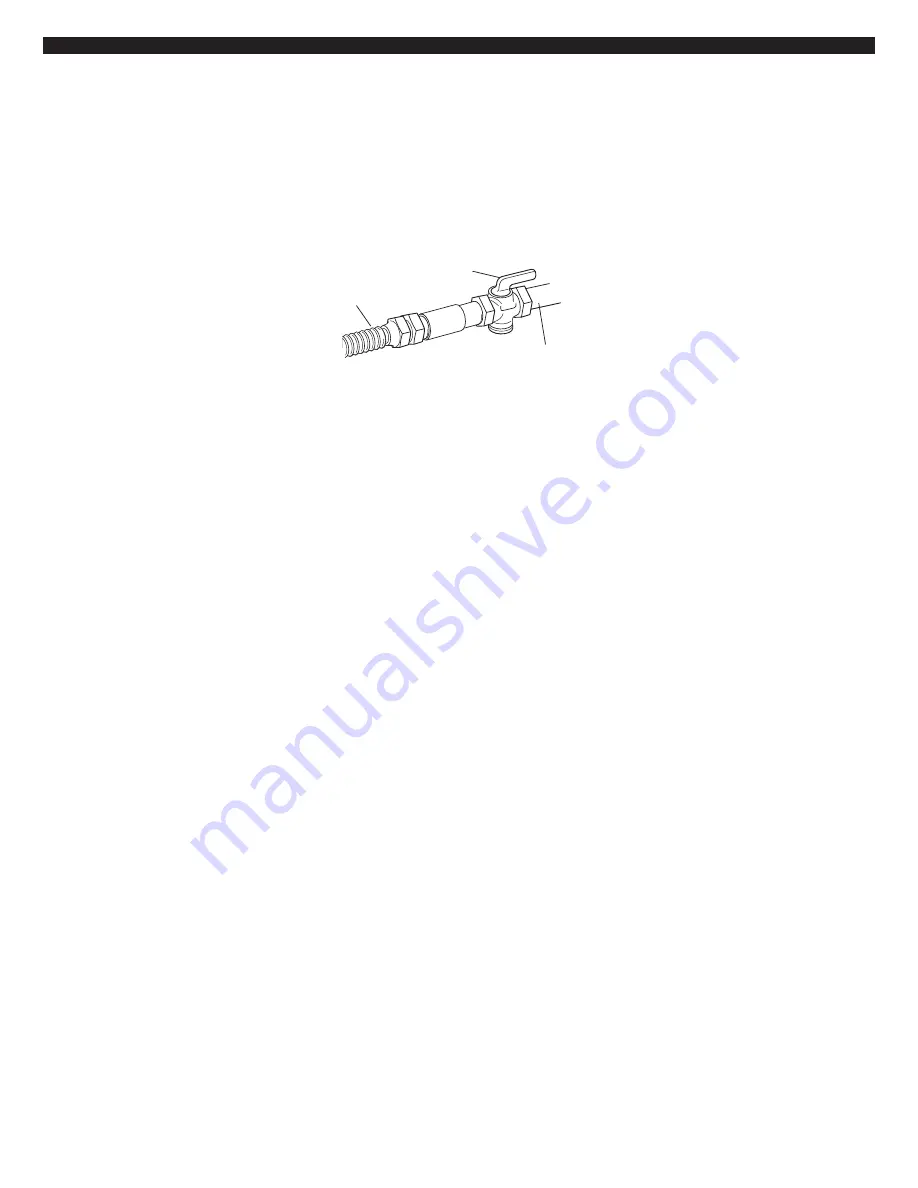

shutoff valve

“open” position

to dryer

rigid gas supply

line

Recommended gas line connection

method.

If local codes permit, it is

recommended that new flexible metal

tubing, design-certified by AGA or

CSA, be used for connecting the

appliance to the rigid gas supply line.

(The gas pipe which extends

through the lower rear of the

appliance has 3/8-inch male pipe

thread.)

Copies of the standards listed may be

obtained from:

* CSA International

8501 East Pleasant Valley Road

Cleveland, Ohio 44131-5575

Optional gas line connection

method.

When acceptable to the gas supplier

and local codes, 3/8-inch approved

tubing may be used for lengths under

20 feet. For lengths over 20 feet,

larger tubing should be used.

A combination of pipe fittings must

be used to connect the dryer to the

gas line.

Pipe-joint compounds resistant to the

action of L.P. gas must be used.

An elbow and connector between

tubing and dryer pipe may be

needed to prevent kinking.

A 1/8-inch NPT plugged tapping,

accessible for test gauge connection,

must be installed immediately

upstream of the gas supply

connection to the dryer.

The dryer must be disconnected

from the gas supply piping system

during any pressure testing of that

system at test pressures in excess

of 1/2 psi.

The dryer must be isolated from

the gas supply piping system by

closing the equipment shutoff

valve during any pressure testing

of the gas supply piping system at

test pressures equal to or less

than 1/2 psi.

Supply line requirements:

Provide a 1/2-inch IPS rigid gas

supply line to the dryer location.

An individual manual shutoff valve

must be installed within 6 feet of the

dryer in accordance with the National

Fuel Gas Code ANSI Z223.1 latest

edition*.