11

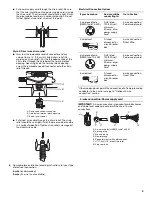

3. Connect ground wire (green or bare) of direct wire cable to

external ground conductor screw. Tighten screw.

4. Place the hooked ends of the other direct wire cable wires

under the outer terminal block screws (hooks facing right).

Squeeze hooked ends together. Tighten screws.

5. Tighten strain relief screw.

6. Insert tab of terminal block cover into slot of dryer rear panel.

Secure cover with hold-down screw.

7. You have completed your electrical connection. Now go to

“Venting Requirements.”

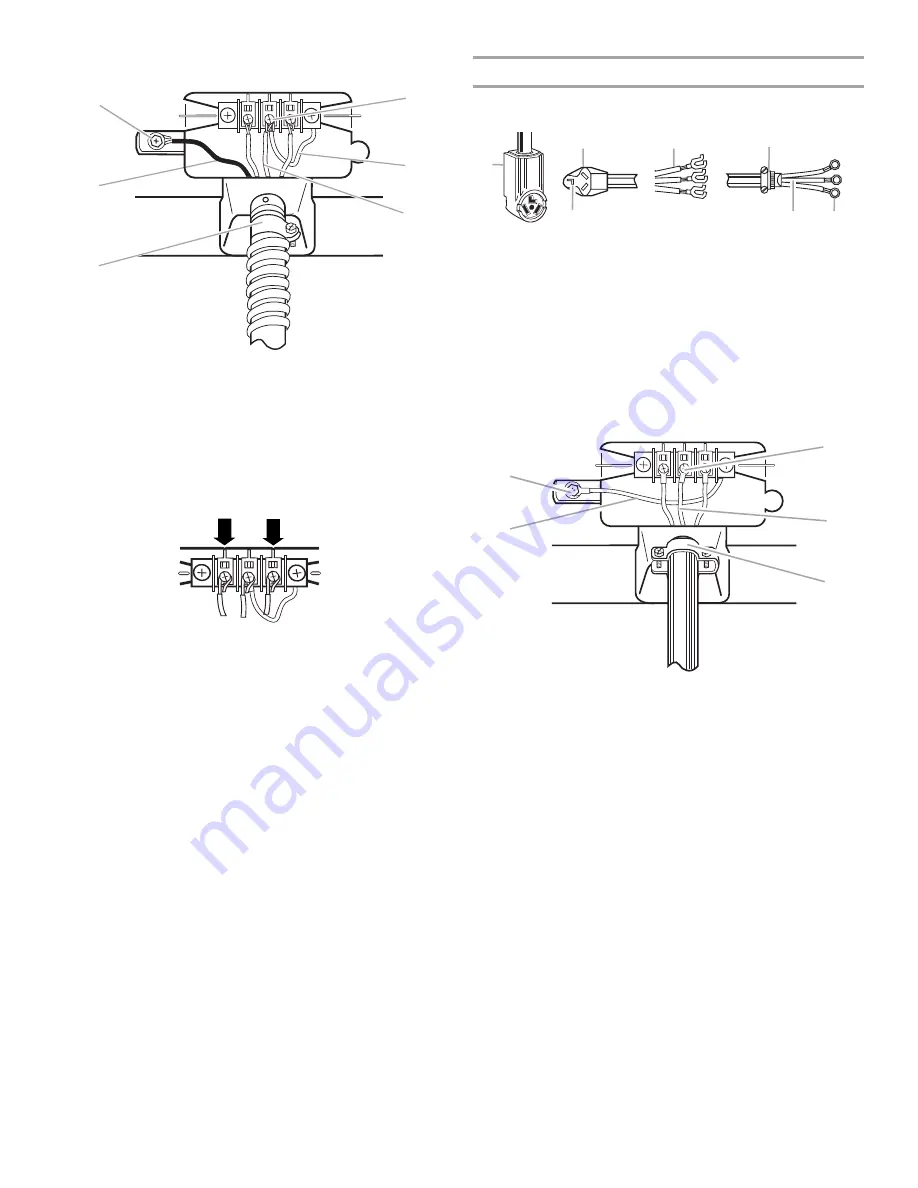

3-wire connection: Power supply cord

Use where local codes permit connecting cabinet-ground

conductor to neutral wire.

1. Loosen or remove center silver-colored terminal block screw.

2. Connect neutral wire (white or center wire) of power supply

cord to the center, silver-colored terminal screw of the

terminal block. Tighten screw.

3. Connect the other wires to outer terminal block screws.

Tighten screws.

4. Tighten strain relief screws.

5. Insert tab of terminal block cover into slot of dryer rear panel.

Secure cover with hold-down screw.

6. You have completed your electrical connection. Now go to

“Venting Requirements.”

A. External ground conductor screw

B. Ground wire (green or bare) of power supply cable

C. ¾" (1.9 cm) UL listed strain relief

D. Center silver-colored terminal block screw

E. Neutral ground wire

F. Neutral wire (white or center wire)

A

B

C

D

E

F

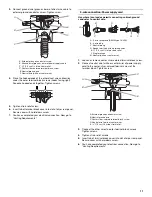

A. 3-wire receptacle (NEMA type 10-30R)

B. 3-wire plug

C. Neutral prong

D. Spade terminals with up turned ends

E.

³⁄₄

" (1.9 cm) UL listed strain relief

F. Ring terminals

G. Neutral (white or center wire)

A. External ground conductor screw

B. Neutral ground wire

C. Center silver-colored terminal block screw

D. Neutral wire (white or center wire)

E.

³⁄₄

" (1.9 cm) UL listed strain relief

A

B

D

C

E

F

G

A

B

C

D

E