5

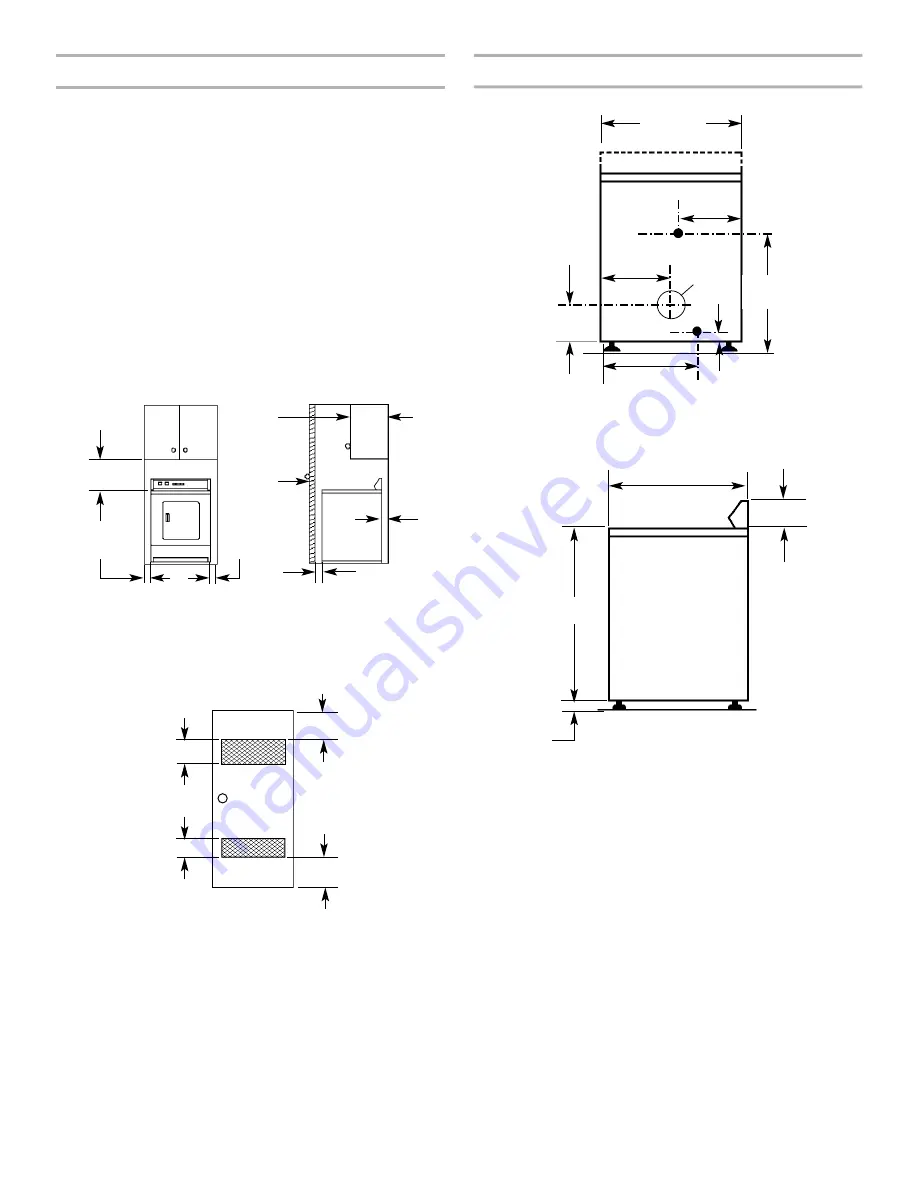

Product Dimensions

Recessed

front view

Closet

side view

Minimum Installation Clearances

*Additional clearances for wall, door and floor moldings may be required or if

external exhaust elbow is used.

Closet

door

Front

View

3" (76 mm)

3" (76 mm)

0" (0 mm)

Closet

door

14"

(356 mm)

max.

1" (25 mm)

0" (0 mm)

15"

(381 mm)*

0"

(0 mm)

29" (737 mm)

16"

(406 mm)

1"

(25 mm)

ELECTRIC

GAS

EXHAUST

4

�⁄�

"

(121 mm)

14

��⁄��

"

(371 mm)

1

�⁄�

" (32 mm)

7

�⁄�

"

(181 mm)

Back view

Side view

28

�⁄�

"

(718 mm)

18

�⁄�

"

(467 mm)

25

�⁄�

" (648 mm)

35"

(889 mm)

4"

(102 mm)

dia.

*Opening is the minimum for a closet door.

Louvered doors with equivalent air openings are acceptable.

24 in

2

(1.55 m

2

)*

48 in

2

.

(3.10 m

2

)*

4

Location Requirements

If installing a gas dryer:

IMPORTANT: Observe all governing codes and ordinances.

Check code requirements: Some codes limit or do not permit

installation of clothes dryers in garages, closets, or sleeping

quarters. Contact your local building inspector.

Make sure that lower edges of the cabinet, plus the back and

bottom sides of the dryer, are free of obstructions to permit

adequate clearance of air openings for combustion air. See

“Recessed Area and Closet Installation Instructions” below for

minimum spacing requirements.

NOTE: The dryer must not be installed in an area where it will be

exposed to water and/or weather.

Recessed Area and Closet Installation Instructions

This dryer may be installed in a recessed area or closet. For

recessed area and closet installations, minimum clearances

can be found on the serial tag on the dryer.

The installation spacing is in inches and is the minimum

allowable. Additional spacing should be considered for ease

of installation, servicing, and compliance with local codes and

ordinances.

If closet door is installed, the minimum unobstructed air opening

in the top and bottom is required. Louvered doors with equivalent

air openings are acceptable.

The dryer must be exhausted outdoors.

No other fuel-burning appliance may be installed in the same

closet as the dryer.

INSTALLATION REQUIREMENTS

WARNING

Explosion Hazard

Keep flammable materials and vapors, such as

gasoline, away from dryer.

Do not install in a garage.

Failure to do so can result in death, explosion, or fire.

Tools and Parts

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools listed

here.

Tools needed

8" or 10" pipe wrench

8" or 10" adjustable wrench

Flat-blade screwdriver

Phillips screwdriver

Adjustable wrench that opens to 1" (25 mm) or hex-head

socket wrench

Level

5/16

" socket wrench

Utility knife

Vent clamps

Pipe-joint compound resistant to LP gas

Caulk gun and caulk (for installing new exhaust vent)

Pliers

Putty knife

Parts supplied

Remove parts bag from dryer drum. Check that all parts were

included.

Dryer foot (4)

5

Product Dimensions

Recessed

front view

Closet

side view

Minimum Installation Clearances

*Additional clearances for wall, door and floor moldings may be required or if

external exhaust elbow is used.

Closet

door

Front

View

3" (76 mm)

3" (76 mm)

0" (0 mm)

Closet

door

14"

(356 mm)

max.

1" (25 mm)

0" (0 mm)

15"

(381 mm)*

0"

(0 mm)

29" (737 mm)

16"

(406 mm)

1"

(25 mm)

ELECTRIC

GAS

EXHAUST

4

�⁄�

"

(121 mm)

14

��⁄��

"

(371 mm)

1

�⁄�

" (32 mm)

7

�⁄�

"

(181 mm)

Back view

Side view

28

�⁄�

"

(718 mm)

18

�⁄�

"

(467 mm)

25

�⁄�

" (648 mm)

35"

(889 mm)

4"

(102 mm)

dia.

*Opening is the minimum for a closet door.

Louvered doors with equivalent air openings are acceptable.

24 in

2

(1.55 m

2

)*

48 in

2

.

(3.10 m

2

)*