8

If the LOW flame needs to be

adjusted:

a. Remove the

control knob.

b. Hold the knob

stem with a

pair of pliers.

Use a small

flat-head

screwdriver to

turn the screw located

in the center of the control knob stem

until the flame is the proper size.

c. Replace the control knob.

d. Test the flame by turning the control

from “LO” to “HI”, checking the flame

at each setting.

adjustment

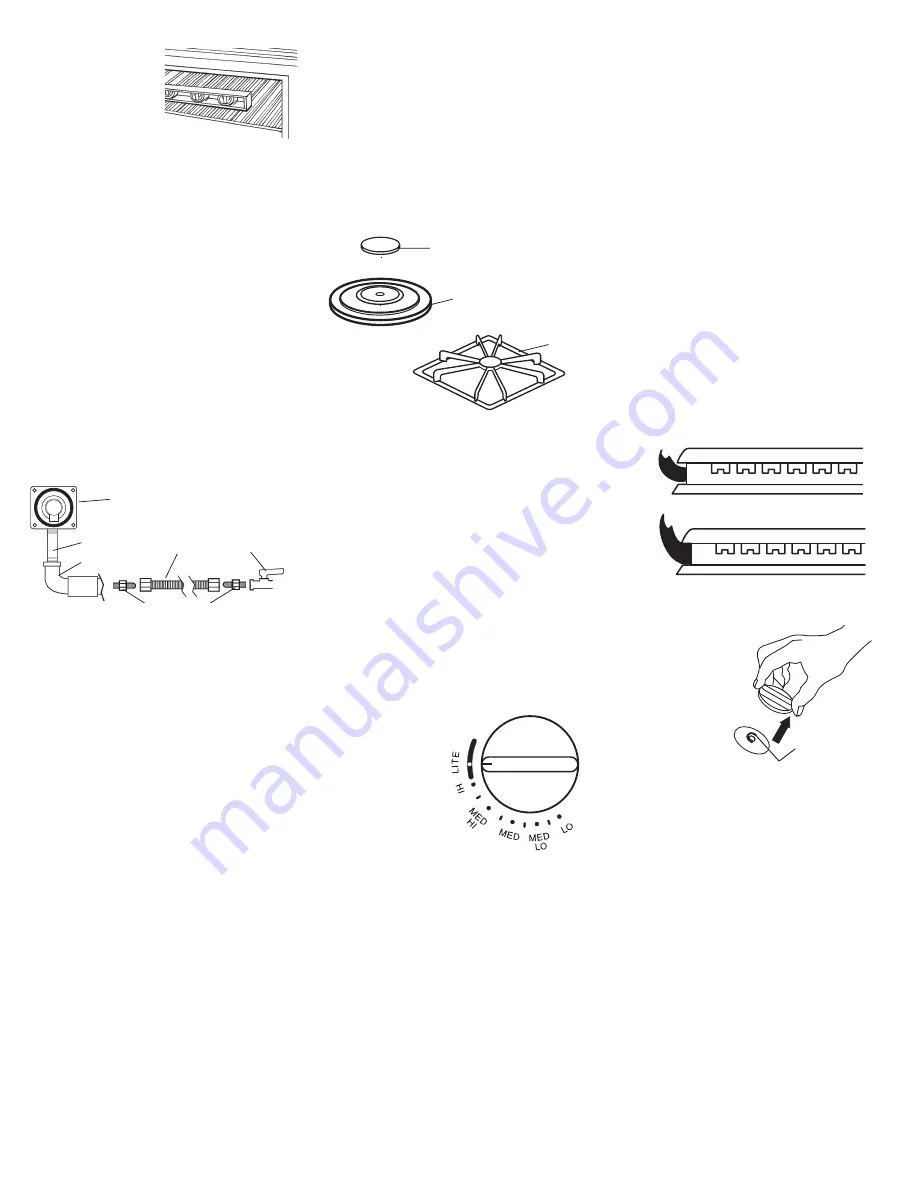

screw

23.

Remove the oven rack. Remove

the oven bottom and place it on a

protected surface.

22.

Adjust the height of top burner

flames (some models).

The cooktop LOW burner flame should

be a steady blue flame approximately

1/4" (0.64 cm) high. It can be adjusted

using the adjustment screw in the center

of the valve stem. The valve stem is

located directly underneath the

control knob.

20.

Check

the operation of

the cooktop

burners. Push in

and turn each

control knob to

the “LITE”

position. The

flame should light

within 4 seconds. The first time a burner

is lighted it may take longer than 4

seconds to light because of air in gas

line.

19.

Remove cooktop burner caps

and grates from parts package. Align

notches in burner caps with pins in

burner base. Burner caps should be level

when properly positioned. Place burner

grates over burners and caps.

burner

grate

burner

cap

burner

base

Electronic Ignition System —

Initial lighting and gas flame

adjustments.

Cooktop and oven burners use electronic

ignitors in place of standing pilots. When

the cooktop control knob is turned to the

“LITE” position, the system creates a

spark to light the burner. This sparking

continues, as long as control knob is

turned to “LITE”.

When the oven control is turned to the

desired setting, a glow bar heats up

bright orange and ignites the gas. No

sparking occurs and the glow bar

remains on while the burners operate.

21.

If burners do not light properly,

turn cooktop control knob to the “OFF”

position. Check that the power supply

cord is plugged in and the circuit breaker

or fuse has not blown. Check that the gas

shutoff valves are set to the “OPEN”

position. Repeat Step 18. If a burner does

not light at this point, contact your dealer

or authorized service company for

assistance.

high flame

low flame

Top burner flame appearance:

18.

Plug power supply cord into

grounded outlet.

17

. Test for gas leaks. Leak testing

shall be conducted according to the

following instructions:

Test all connections by brushing on an

approved non-corrosive leak-detection

solution. Bubbles will show a leak.

Correct any leak found.

13.

Place rack

in oven. Place level

on rack, first side to

side; then front to

back.

If the range is not

level, pull range forward until the rear

leveling leg is removed from the anti-tip

bracket. Adjust the leveling legs up or

down. Then slide range back into position.

Check that leveling leg is engaged in anti-

tip bracket.

NOTE:

Oven must be level for satisfactory

baking conditions.

pressure regulator

and valve assembly

flexible

connector

3" (7.6 cm)

connector

90° elbow

manual

shutoff valve

All connections must be wrench-

tightened.

1/2" (1.3 cm) flare union adapters

15.

Use pipe-joint compounds

appropriate for use with L.P. gas to seal

all gas connections. If flexible connectors

are used, be certain connectors are not

kinked.

16.

Open the shutoff valve in the

gas supply line. Wait a few minutes for

the gas to move through the gas line.

14.

Assemble the flexible connector

from the gas supply pipe to the pressure

regulator, located in the lower left side of

the storage drawer area, in this order:

shutoff valve, 1/2" (1.3 cm) flare union

adapter, flexible connector, 1/2" (1.3 cm)

flare union adapter. Seal all openings in

floor or wall wherever range is installed.