4-2

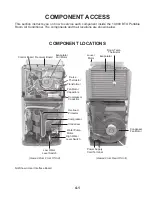

REMOVING THE CABINET

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug air conditioner or disconnect power.

2. Disconnect the vent duct from the air

conditioner by turning it counterclockwise

and lifting it off the vent opening.

3. Remove the seven screws from the cabi-

net rear.

Screw (1 of 7)

Cabinet

Rear

Vent Duct

4. Pull the rear of the cabinet off the unit.

Cabinet

Rear

Remove

Summary of Contents for ACP102PR

Page 4: ... iv NOTES ...

Page 10: ...1 6 NOTES ...

Page 26: ...3 12 NOTES ...

Page 60: ...6 2 NOTES ...

Page 61: ...6 3 NOTES ...

Page 62: ...6 4 NOTES ...

Page 64: ......