3-6

REMOVING THE MECHANICAL HUMIDISTAT,

LIGHT, AND POWER SUPPLY CORD

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug dehumidifier or disconnect power.

2. Remove the cabinet from the dehumidi-

fier (see page 3-2 for the procedure).

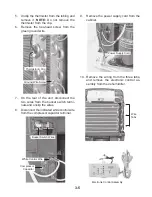

3. Pull the knob off the humidistat shaft.

4. Remove the two hex-head screws from

the control.

5. Unsnap the four top cover tabs from the

mechanical control and remove the cover.

Mechanical Control Screws

Humidistat Knob

Top Cover Tabs

6.

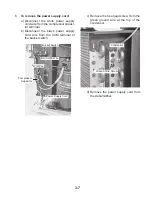

To remove the mechanical humidistat:

a) Disconnect the brown wire and the

connector with the two black wires

from the mechanical humidistat termi-

nals.

b) Unclip the humidistat from the cover

and remove it.

7.

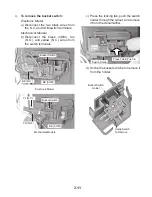

To remove the light:

a) Disconnect the yellow and two white

wires from the light terminals.

b) Unclip the light from the cover and re-

move it.

Mechanical Humidistat

Light

2 BK BN

YL 2 WH

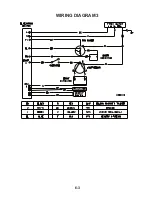

Summary of Contents for AD25BSS

Page 4: ... iv NOTES ...

Page 8: ...1 4 NOTES ...

Page 28: ...3 12 NOTES ...

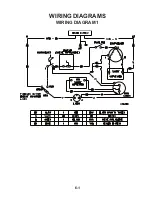

Page 33: ...6 1 WIRING DIAGRAM 1 WIRING DIAGRAMS ...

Page 34: ...6 2 WIRING DIAGRAM 2 ...

Page 35: ...6 3 WIRING DIAGRAM 3 ...

Page 36: ...6 4 NOTES ...

Page 37: ...6 5 NOTES ...

Page 38: ...6 6 NOTES ...

Page 40: ...CORPORATION ...