5 - SET-UP FOR OPERATION

0803_GB_42

- GAS KITCHENS WITH PILOT

04/2008

5.1.5 Power check for operation with liquid gas

Check if the type of injectors used meet the data of the table 1.

Check that the pressure reducer installed in the system has an outlet

pressure which is compliant with paragraph 5.1.2 "Check of power"

(can be checked on the data plate of the appliance or on the table

1).

5.1.6 Operation control

• Start the appliance in accordance with the instructions.

• Check that the appliance does not have any leaks by using a leak-

detecting spray.

• Check ignition and that flame on the main burner lights properly

and is correctly formed, even on low.

• A servicing and maintenance contract is recommended.

5.1.7 Check of pilot flame

For proper regulation, the pilot flame must surround the thermocou-

ple and it must have a perfect appearance; otherwise, check gas

pressure, make sure the injector is clean and has the right diameter

for the gas, see table 1.

5.1.8 Checking the primary air

Both the oven and the open flames are equipped with primary air

adjustment. Air volume flow is correct when there is sufficient pro-

tection against the flame rising when the burner is cold or in case of

flashback when the burner is hot. See table 1.

5.1.9 Operator training

• Explain and show the user how the machine works according to

the instructions, and hand him this manual.

• Remind the user that any structural alterations or any building

modification or renovation may affect the combustion air supply,

thus requiring a second operation check.

5.1.10 Conversion and adjustment

To change over form one kind of gas to another, for example from

methane to liquid gas, or to another type of gas, the use of suitable

injectors for the main burner is required, in accordance with the

table 1.

The injectors of the main burners and pilot for different types of

gas, marked with the relative diameter in hundredths of mm, are in

an envelope which is provided with the appliance. If injectors are

not available please contact the factory with model and serial num-

ber written on technical data sticker. After transformation or adap-

tation, carry out operating checks as described in paragraph 5.1.6

“Operation control”.

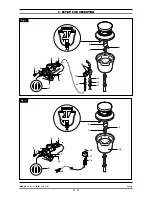

5.1.11 Replacing of open burners injectors

To replace the injector (pos. 1 fig. 1): remove the grill, the flame

spreader and the burner body.

Then unscrew the screw (pos. 2 fig. 1), which secures the primary air

bushing (pos. 3 fig. 1), move air regulation screwing it in to make

the injector accessible, replace the injector with one able for the

type of gas, see table 1, reinstall everything in reverse order.

After fitting the new injectors, reset primary air distance “A” (fig. 1)

see table 1, and fasten the bushing with the appropriate screw.

After the replacement check the seal using a leack detector spray.

5.1.12 Replacement of pilot injectors of open flames

To replace the injector (pos. 12 fig. 1): remove the grill, he flame

spreader and the burner body.

Unscrew the screws (pos. 18 fig. 1), fixing the pilot on the the injec-

tor-holder cup, lift up the pilot to a more convenient position for

unscrew the nut (pos. 11 fig. 1), pull down the nut together the pipe

and the bicone (pos. 13 fig. 1) unfix the injector and replace the

injector with one able for the type of gas, see table 1, install in rever-

se order.

After the replacement check the seal using a leack detector spray.

5.1.13 Setting reduced capacity power

The minimum setting screw (pos. 5 fig. 1) should be adjusted as fol-

lows:

• for operation with LPG it should be screwed all the way down;

• for operation with methane, use the gas flow table to check the

value in l/min with respect to the operating alorific value (meas-

urement in accordance with the volumetric method). Start the

appliance in accordance with the instructions. Turn the knob to

the minimum position and use screw (pos. 5 fig. 1) to adjust the

flow (clockwise = flow reduction; conter-clockwise = flow

increase).

5.1.14 Replacing of solid top injectors

To replace the injector (pos. 1 fig. 2): remove the solid top, the

flame spreader and the burner body.

Then unscrew the screw (pos. 2 fig. 2), which secures the primary air

bushing (pos. 3 fig. 2), move air regulation screwing it in to make

the injector accessible, replace the injector with one able for the

type of gas, see table 1, reinstall everything in reverse order.

After fitting the new injectors, reset primary air distance “A” (fig. 2)

see table 1, and fasten the bushing with the appropriate screw.

After the replacement check the seal using a leack detector spray.

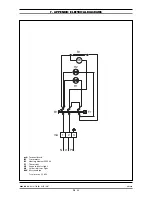

5.1.15 Replacement of burner injector of gas oven GN 2/1

Remove the front/lower unscrew the fixing sight screws. Unscrew

the screw fixing the hanger (pos. 2 fig. 3) of the injector-holder

(pos. 3 fig. 3), unscrew the screw (pos. 5 fig. 3) and extract the injec-

tor-holder from its housing. Now the injector (pos. 4 fig. 3) is easily

accessible, replace the injector with one able for the type of gas, see

table 1, install in reverse order.

After fitting the new injectors, reset primary air distance “A” see

table 1.

After the replacement check the seal using a leack detector spray.

5.1.16 Replacement of pilot injector of gas oven GN 2/1

Remove the front/lower unscrew the fixing sight screws.

Remove the plug (pos. 11 fig. 3) and with the help of a screwdriver

unscrew the injector (pos. 12 fig. 3), replace the injector with one

able for the type of gas, see table 1, install in reverse order.

At last replace the plug (pos. 11 fig. 3) and gasket (pos. 13 fig. 3).

After the replacement check the seal using a leack detector spray.

5.2 Maintenance

Attention! Before doing any repair or maintenance

work, unplug the appliance.

The following maintenance program should be carried out at least

once a year by qualified personnel with license:

• Check that all the safety and adjustment devices are working

properly;

• Check that the burners are working properly with regard to:

- ignition

- combustion safety;

Check functioning of the appliance as described in paragraph 5.1.6

“Operation control”.

If it should be necessary to clean the open flame burners, proceed

as follows:

• Remove the grills, the flame spreaders and the bodies of the

burners;

• Clean the parts with water and detergent and an appropriate

12

· 20