5.1 Preparation and Start-up

Before starting up the appliance, remove the protective wrapping.

Then carefully clean the working surface and the external parts with

lukewarm water and detergent, using a damp rag to remove all traces

of anti-rust material applied in the factory, then dry with a clean cloth.

5.1.1 Start-up

Before starting up the appliance, check that its specifications (cate-

gory and type of gas used) match those of the family and group of

the gas available locally.

If not, it is necessary to adapt the appliance to the gas family or

group required (see paragraph “Conversion and adjustment”).

To start up the appliance, see the instructions for regular use.

5.1.2 Check of power

The appliances must be used with the specific nozzles for the nomi-

nal power.

The power may be:

• the nominal power indicated on the data plate of the appliance;

• the reduced capacity power.

These nozzles are shown in table 1 “Technical data”.

Nominal power is also obtained in respect of the supply pressure:

• from 15 to 22.5 mbar for gases of the second family (G20/methane)

• from 25 to 45 mbar for gases of the 3rd family

(G30/propane, G31/butane)

The appliance shall not be operated outside the above-mentioned

pressure ranges.

To adjust power with reduced capacity, use the data in table 1.

If you wish to further check the nominal power, you may do so by

using a gas meter according to the so-called "volumetric method".

A simple inspection is usually enough to check if nozzles are func-

tioning correctly.

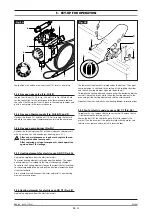

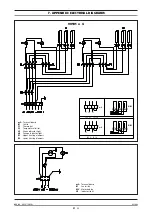

5.1.3 Checking the input pressure (Fig. 1)

Input pressure should be measured using a fluid measuring gauge

(e.g. a gooseneck pipe, min. resolution 0.1 mbar).

Remove lock screw (22) from the pressure intake tube and connect the

gauge hose: once measurement is complete, replace the screw (22).

4 - ISTRUZIONI PER LA MESSA IN OPERA

5 - SET-UP FOR OPERATION

063_03

- GAS KITCHENS

10

· 22

03/2006

If the type of gas indicated on the data plate of the appliance does

not correspond to the gas which is present, refer to the paragraph

"Conversion and adaptation".

4.3.2 Statutory regulations and technical requirements

During installation of the appliance, the following regulations must

be adhered to:

• Relevant legal directives;

• Local building and combustion regulations;

• "Technical rules for gas systems" worksheet;

• "Technical rules for liquid gas" worksheet;

• “Gas installations in industrial kitchens” worksheet;

• Relative accident prevention standards;

• Local gas utility regulations.

• Local building and fire codes.

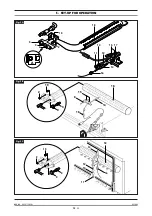

4.3.3 Installation

Assembly, installation and maintenance, i.e.:

•

assembly, gas connection, check of power, conversion or adapta-

tion and start-up;

Ask for approval from the local gas company.

4.3.4 Installation operations

To level the appliance correctly, adjust the height of the feet.

4.3.5 Gas connection

The R 3/4” gas connection of the appliance to the gas pipeline can

either be permanently fixed to the mains or made detachable using

an approved cock.

If hoses are used, they must be in stainless steel and in compliance

with the DIN 3383, part 1 or DIN 3384 regulations.

After completing gas connection, check for leaks using a special

leak-detector spray.

4.3.6 Smoke extraction

These kitchens are type A appliances, thus no smoke extraction sys-

tem is required.

For the ventilation of the room where the appliance is installed,

refer to related legislation.

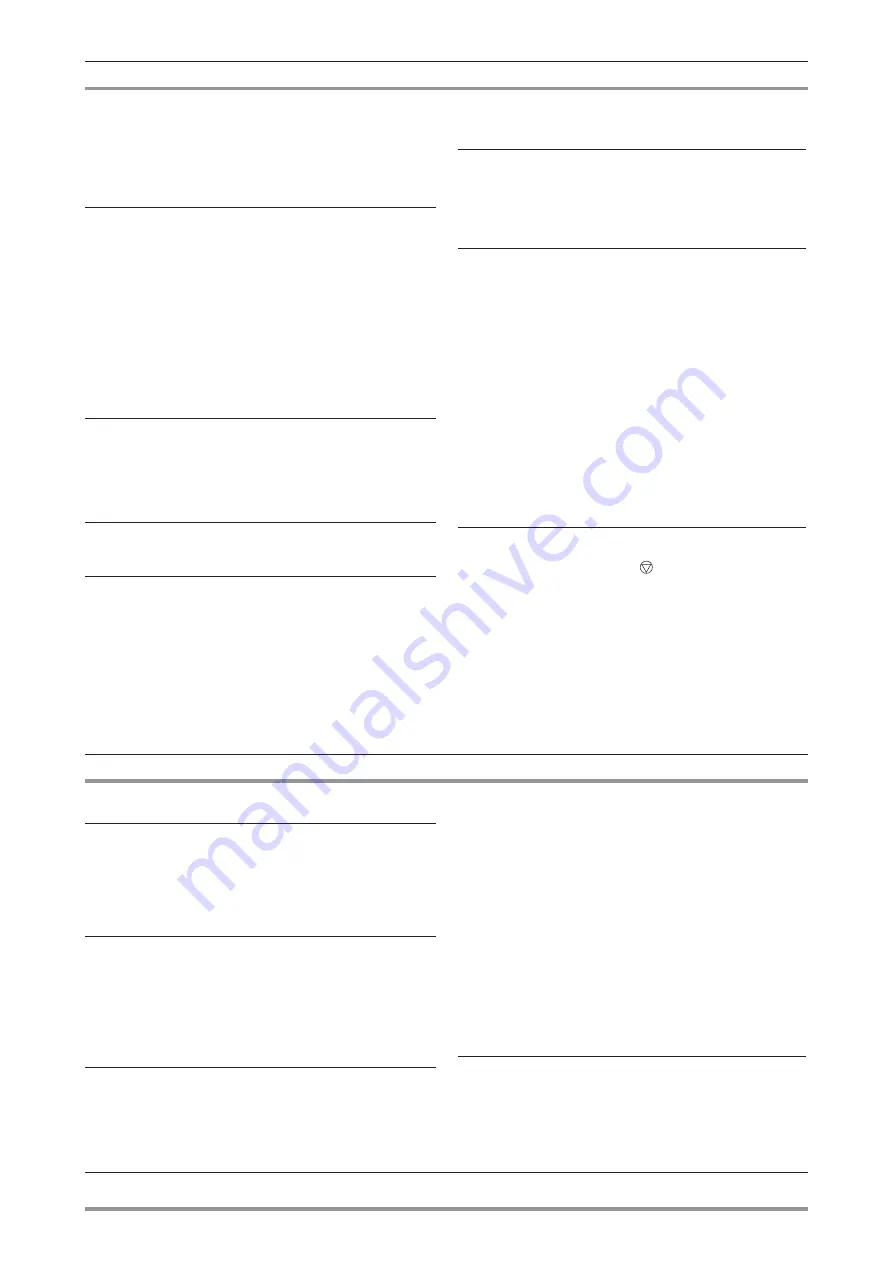

4.3.7 Electrical connection

Before connecting the unit to the mains, check that:

• The mains voltage corresponds to the values shown on the data

plate;

• The earth is in working order;

• The power cord is suitable to the electrical input of the appli-

ance (see table 1 on page 8).

Also, up the line from the unit, there must be a device with contact

opening of at least 3 mm which makes it possible to disconnect the

appliance in omnipolar mode.

To this end, for example, safety contactors may be used.

The omnipolar switch must be located near the appliance and be

readily accessible.

The power cord must be approved and have a section which is suit-

able for the appliance.

The cord must be at least type H07 RN-F.

4.3.8 Equipotential

The appliance must be hooked up to a unipotential system. The

required terminal is located near the cord inlet.

It is marked by a tag with a symbol

.