9

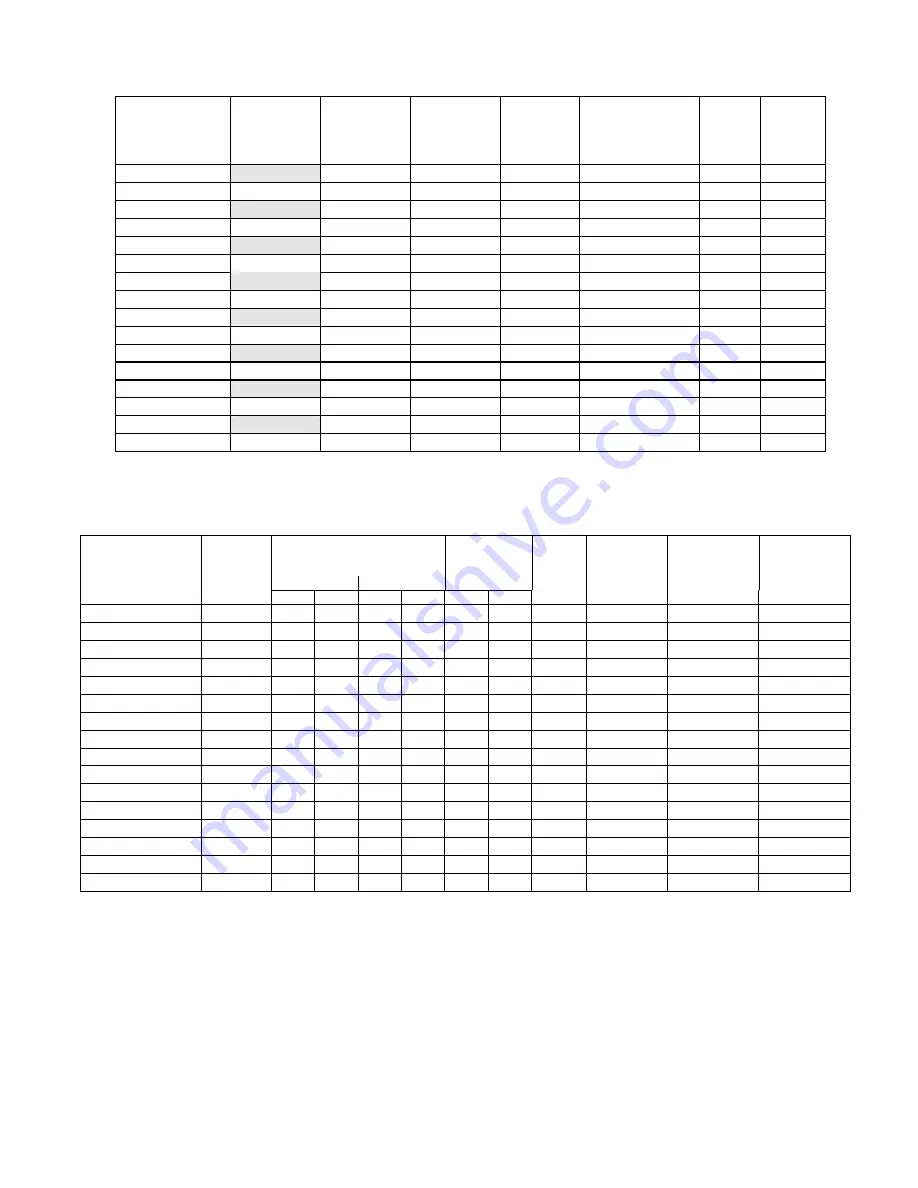

TECHNICAL DATA

MODEL

COOLING

WATER

USAGE

L/HOUR (1)

ICE

PRODUCTION

WATER

USAGE

L/HOUR (1)

TOTAL

WATER

USAGE

L/HOUR (1)

NET

WEIGHT

(KG)

DIMENSIONS

CRATED

X*Y*Z

GROSS

WEIGHT

(KG)

VOLUME

(M

3

)

WHP AGS 836

4

4

36

490x595x765

41

0.22

WHP AGS 837

15

4

19

36

490x595x765

41

0.22

WHP AGS 838

4

4

39

490x595x830

44

0.24

WHP AGS 839

15

4

19

39

490x595x830

44

0.24

WHP AGS 840

5

5

42

490x595x960

46

0.28

WHP AGS 841

25

5

30

42

490x595x960

46

0.28

WHP AGS 842

7

7

48

610x640x960

56

0.37

WHP AGS 843

33

7

40

48

610x640x960

56

0.37

WHP AGS 844

6

6

55

690x640x1080

66

0.47

WHP AGS 845

35

6

41

55

690x640x1080

66

0.47

WHP AGS 846

23

8

60

770x640x1080

74

0.53

WHP AGS 847

45

23

68

60

770x640x1080

74

0.53

WHP AGS 848

11

12

80

940x640x1080

95

0.65

WHP AGS 849

53

11

64

80

940x640x1080

95

0.65

WHP AGS 850

11

11

98

900*650*1200

113

0.702

WHP AGS 851

70

11

81

98

900*650*1200

113

0.702

MODEL

REFRIG.

CHARGE

HIGH PRESSURE

LOW

PRESSURE

TOTAL

CURR.

FUSES

COMPRESSOR

OUTPUT

TOTAL

OUTPUT

MÍNIMUM

MAXIMUM

AVERAGE

(2)

(1)

(2)

(GR)

Kg/cm

2

Psi

Kg/cm

2

Psi

Kg/cm

2

Psi

(A)

(A)

(W)

(W)

WHP AGS 836

260

16

228

17

240

2.5

38

1.5

10

175

220

WHP AGS 837

190

16

228

17

240

2.5

38

1.5

10

175

220

WHP AGS 838

260

16

228

17

240

2.5

38

1.5

10

190

220

WHP AGS 839

190

16

228

17

240

2.5

38

1.5

10

190

220

WHP AGS 840

270

16

228

17

240

2.5

38

1.7

10

190

270

WHP AGS 841

205/195

16

228

17

240

2.5

38

1.7

10

190

270

WHP AGS 842

270

16

228

17

240

2.5

38

2

10

210

300

WHP AGS 843

290

16

228

17

240

2.5

38

2

10

210

300

WHP AGS 844

370/390

16

228

17

240

2.5

38

2.2

10

210

310

WHP AGS 845

370

16

228

17

240

2.5

38

2.2

10

210

310

WHP AGS 846

370/380

16

228

17

240

2.5

38

2.8

10

365

450

WHP AGS 847

360

16

228

17

240

2.5

38

2.8

10

365

450

WHP AGS 848

425

16

228

17

240

2.5

38

3

10

440

500

WHP AGS 849

425

16

228

17

240

2.5

38

3

10

440

500

WHP AGS 850

400

16

228

17

240

2.5

38

6

10

440

1000

WHP AGS 851

340

16

228

17

240

2.5

38

6

10

440

1000

1) Data obtained at room temperature (20°C), water introduced at 15°C; water quality = 500ppm

2) Maximum consumption obtained at room temperature = 43°, according to UNE climate classification Class T

(Tropicalised).

NOTE: Expansion controlled by capillary.