20

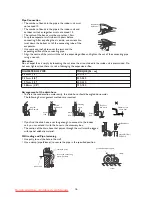

Expelling air

• Screw down the cap of both the gas shut-off valve

and the liquid shut-off valve as well as the nut of the

service port.

• Use an Allen wrench to turn the liquid shut-off valve

90° counterclockwise, and close it again after 10

seconds.

• Use soapy water to check for gas leakage, especially

at all joints. If there is no gas leakage, turn the liquid

shut-off valve 90° counter-clockwise again.

• Press the cork of the service port at the gas shut-off

valve. After 10 seconds, a foggy gas is discharged,

meaning the air inside has been expelled.

• Use an Allen wrench to turn both the liquid shut-off

valve and the gas shutoff valve counter-clockwise

until they are fully open and then replace the valve

caps and tighten them.

Expansion of the pipe orifice

• Use a pipe cutter to cut off the broken pipe orifice.

• Remove burrs at the cut of the pipe orifice.

• Insert a nut into the pipe and expand the orifice

with specified tools, reamers for example.

• Check the quality of expanding technique.

Adding refrigerant

• If the connecting pipe is longer than 7 metres, add refrigerant as needed. (Cool only type) added

amount A=(Lm-7m) x 15g/m; (Heat pump type) added amount A= (Lm-7m) x 50g/m. (A: amount of

added refrigerant, L: the length of connecting pipe)

liquid

connecting pipe

allen wrench

gas

connection

pipe

valve

nuts

service port

service port cap

gas shut-off valve

liquid shut-off valve

Copper pipe

Oblique

Roughness

Burr

Burr

Reamer

Outer diameter

A (mm)

6.35mm (1/4")

2.0-2.5

9.52mm (3/8")

3.0-3.5

12.7mm (1/2")

3.5-4.0

15.88mm (5/8")

4.0-4.5

The length of connecting pipe (m)

7

8

9

10

(Cool only type) added amount (g)

0

15

30

45

(Heat pump type) added amount (g)

0

50

100

150

Downloaded from AC-Manual.com Manuals