7

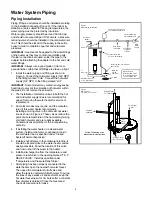

The Temperature & Pressure Relief Valve:

•

Must be connected to an adequate discharge line.

•

Must not be in contact with any electrical part.

•

Must not be rated higher than the working pressure

shown on the data plate of the water heater.

The Discharge Line:

•

Must not be smaller than the pipe size of the relief

valve or have any reducing coupling installed in the

discharge line.

•

Must not be capped, blocked, plugged, or contain

any valve between the relief valve and the end of

the discharge line.

•

Must terminate a maximum of six inches above a

fl

oor drain or external to the building. In cold climates,

it is recommended that the discharge pipe be termi-

nated at an adequate drain inside the building.

•

Must be capable of withstanding 250° F (121°

C)

without distortion.

•

Must be installed to allow complete drainage of

both the valve and discharge line.

T&P Relief Valve and Pipe Insulation:

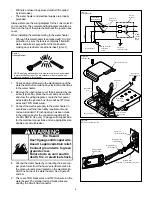

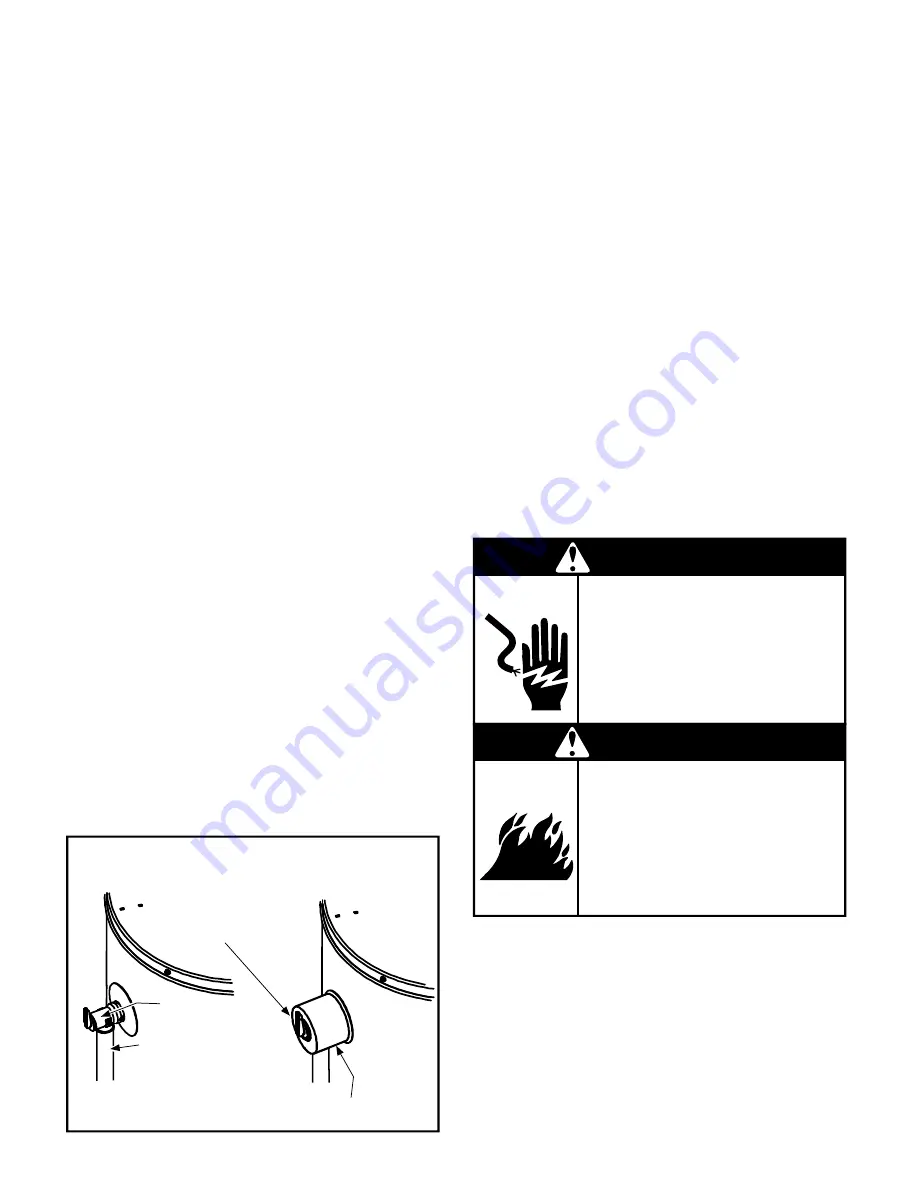

1. Locate the temperature and pressure relief valve on

the water heater (also known as a T&P Relief Valve,

(Figure 6).

2. Locate the slit running the length of the insulation.

3 Spread this slit open and slip it up under the T&P

Relief Valve (See Figure 6). Apply gentle pressure to

the insulation to ensure it is fully seated on the T&P

Relief Valve. Once sealed, secure the insulation with

a section of duct tape, electrical tape, or equivalent.

IMPORTANT: The insulation or tape must not block

the discharge opening or hinder access to the manual

relief lever. Ensure a discharge pipe is installed into

the T&P valve discharge opening per the instructions

manual.

4. Locate the hot water (outlet) & cold water (inlet) pipes

to the water heater.

5. Locate the slit running the length of a section of pipe

insulation.

6. Spread the slit open and slip the insulation over

the cold water (inlet) pipe. Apply gentle pressure

along the length of the insulation to ensure it is fully

seated around the pipe. Also ensure that the base of

insulation is flush with the water heater. Once seated,

secure the insulation with duct tape, electrical tape, or

equivalent.

7. Repeat steps 5 through 6 for the hot water (outlet)

pipe.

8. Add additional sections of pipe insulation as needed.

Solar Installation

If this water heater is used as a solar storage heater or

as a backup for the solar system, the water supply

temperatures to the water heater tank may be in excess

of 120° F (48.8° C). A mixing valve or other temperature

limiting valve must be installed in the water supply line to

limit the supply temperature to 120° F (48.8° C).

Note:

Solar water heating systems can often supply water

with temperatures exceeding 180° F (82.2° C) and may

result in water heater malfunction.

Electrical Requirements

Electric Shock Hazard

Disconnect power before

servicing.

Replace all parts and panels

before operating.

Failure to do so can result in

death or electric shock.

WARNING

Fire Hazard

Use 10 gauge solid copper wire.

Use a UL approved strain relief.

Connect ground wire to green

ground screw.

Failure to do so can result in

death, fire, or electrical shock.

WARNING

If you lack the necessary skills required to properly

install the electrical wiring to this water heater, do not

proceed, but have a quali

fi

ed electrician perform the

installation.

When making the electrical connections, always make

sure:

•

The electrical supply has the proper overload fuse

or circuit breaker protection.

•

Wire sizes and connections comply with all

applicable codes.

T&P Relief Valve Insulation

Manual Relief Lever

T&P Relief Valve

T&P Relief Valve

Drain Line

Figure 6

Temperature and Pressure

Relief Valve Installation