Natural gas conversion

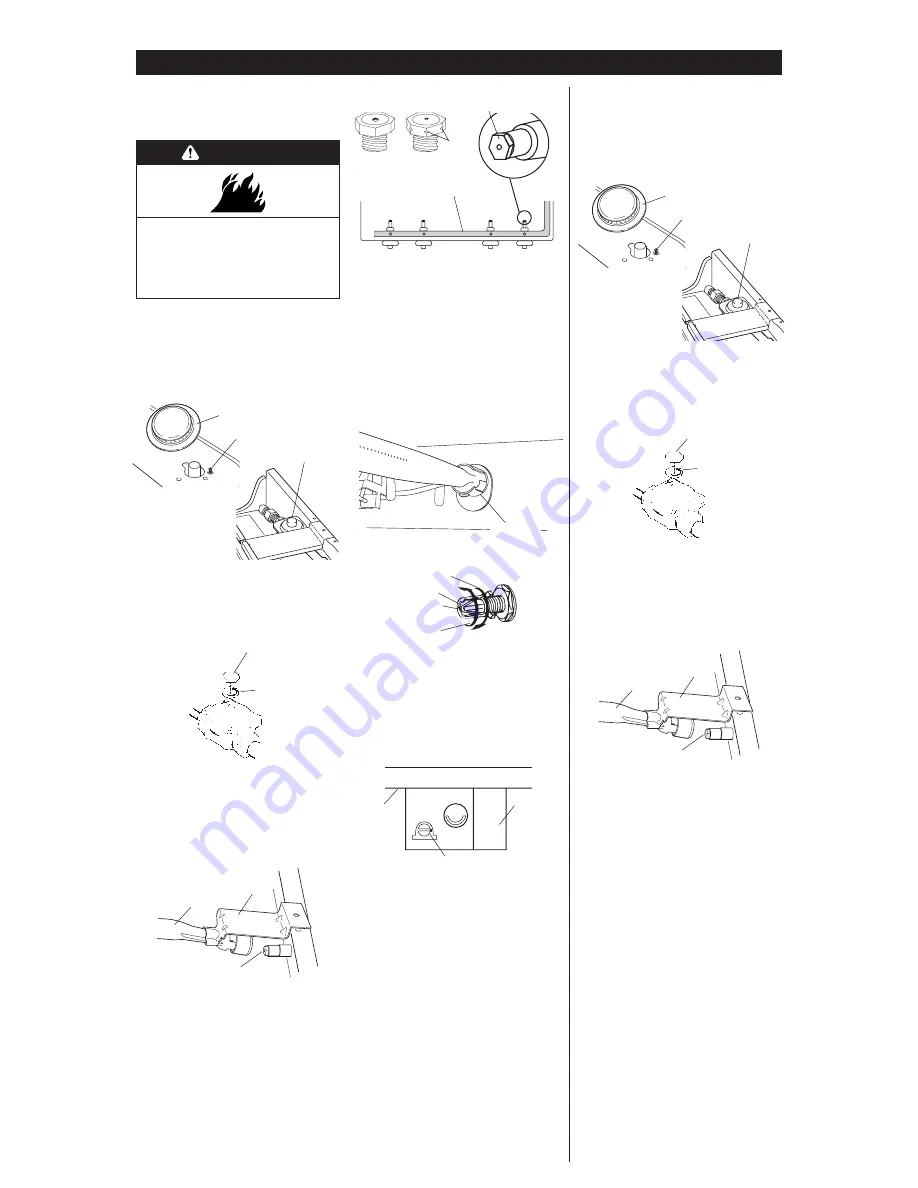

1.

Check that the manual shutoff valve in the

gas supply line has been turned off.

2.

Remove burner grates, burners and

screws. Lift cooktop. Note: There is no cooktop

support rod.

Locate pressure regulator.

DO NOT REMOVE THE PRESSURE REGULATOR.

3.

Pressure regulator:

Remove the cap from

the pressure regulator. Turn the cap over so that

N or NAT is visible. Replace the cap.

Gas conversions

Gas conversions (from Natural gas to L.P. gas; or

from L.P. gas to Natural gas) must be done by a

qualified installer.

Page 7

L.P. gas conversion

1.

Complete installation sections A-C (Pages

4-5) before converting cooktop to L.P. gas.

Check

that the manual shutoff valve in the gas supply

line has been turned off.

2.

Remove burner grates, burners and

screws. Lift cooktop. Note: There is no cooktop

support rod.

Locate pressure regulator.

4.

Cooktop burners:

Check that the control

knobs are in the “OFF” position. Remove all

control knobs. Remove manifold panel. Lift front

of bracket and push tube and bracket assembly

back off orifice.

DO NOT REMOVE THE PRESSURE REGULATOR.

3.

Pressure regulator:

Remove the cap from

the pressure regulator. Turn the cap over so that

LP is visible. Replace the cap.

burner

tube

bracket

orifice

orifice

burner

tube

bracket

4.

Cooktop burners:

Check that the control

knobs are in the “OFF” position. Remove all

control knobs. Remove manifold panel. Lift front

of bracket and push tube and bracket assembly

back off orifice.

5.

Locate L.P. gas orifice spuds in literature

package included with the range. All L.P. gas

spuds are stamped with “65”. Remove Natural

gas orifice spuds using a 3/8" combination

wrench. Install L.P. gas orifice spuds to replace

the Natural gas orifice spuds.

Place Natural gas orifice spuds in plastic parts

bag for future use and keep with literature

package.

Reinstall burner tube and bracket assemblies. Do

not lower cooktop.

orifice spuds

NAT

L.P.

L.R.

L.F.

R.R.

R.F.

gas

manifold

notches

pressure

regulator

burner

screw

pressure

regulator

burner

screw

LP

gasket

LP is visible

NAT

gasket

N or NAT

is visible

6.

Oven burner:

Use 1/2" combination

wrench to turn the orifice hood down snug onto

pin (approximately 2 to 2-1/2 turns).

DO NOT

OVERTIGHTEN.

The burner flame cannot be

properly adjusted if this conversion is not made.

7.

Locate selector key on oven thermostat and

turn clockwise to the L.P. position.

8.

Complete section D, “Gas connection”

Page 5.

9.

Lower cooktop. Reinstall screws to secure

burner tubes to cooktop. Reinstall burners and

grates.

10.

Check for proper flame. The small

inner cone should have a very distinct blue flame

1/4" to 1/2" long. The outer cone is not as distinct

as the inner cone. L.P. gas flames have a slightly

yellow tip. If the flame is noisy or blowing, it is

getting too much air. If the flame is soft and lazy,

it is not getting enough air. If burners need

adjusting, see section E, “Check operation,”

Page 6.

hood

pin

L.P. gas

decrease gas

decrease flame size

Natural gas

increase gas

increase flame size

pre-set at factory for Natural gas

L

P

N

A

T

Remove and replace

orifice spuds.

Note: Burner tube and

brackets not shown.

Fire Hazard

Shut off gas supply line valve.

Make all conversions before turning gas

supply valve back on.

Failure to follow these instructions can

result in explosion, fire or other injury.

WARNING

thermostat

gas

manifold

selector

key

oven burner

orifice behind

air shutter