4.

Oven burner:

Use 1/2" combination

wrench to loosen the orifice hood away from pin

(approximately 2 to 2-1/2 turns). The burner

flame cannot be properly adjusted if this

conversion is not made.

5.

Broil burner:

Use 1/2" combination

wrench to loosen orifice hood away from pin

(approximately 2 to 2-1/2 turns). The burner

flame cannot be properly adjusted if this

conversion is not made.

6.

Reinstall the storage drawer. Complete

installation sections D through E, Pages 5-7.

Checking for proper cooktop burner and oven

flame is very important.

Natural gas flames do not have yellow tips.

Page 8

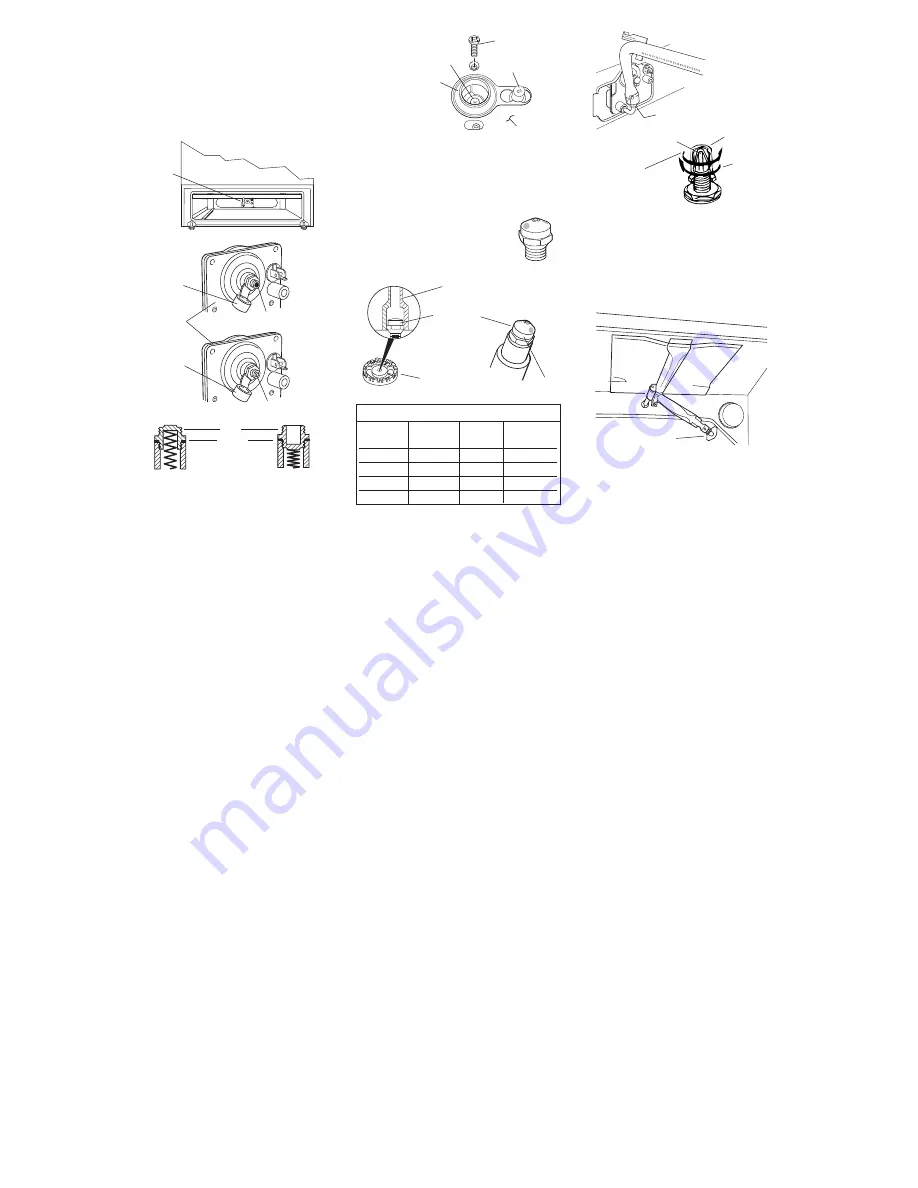

orifice hood

hood

orifice hood

pin

L.P. gas

decrease gas

decrease

flame size

Natural gas

increase gas

increase flame size

pre-set at factory for

Natural gas

Natural gas conversion

1.

Check that main gas supply line has been

shut off and the power supply cord is

disconnected.

DO NOT REMOVE THE PRESSURE REGULATOR.

2.

Open broiler drawer to locate pressure

regulator.

Pressure regulator:

Remove plastic cover. Turn

cap marked “L.P.” on front of pressure regulator

counterclockwise with a wrench to remove.

Do

Not disturb or remove the spring beneath the

cap.

Turn the cap over and reinstall cap on

regulator so that the letter “N” is visible. Replace

plastic cover over cap.

A brass orifice spud is located in the center of

each burner throat about 2" below the cooktop.

Apply masking tape to the end of a 5/16" nut

driver to fit snugly over the orifice spud. Press

driver down onto the spud of the left front burner

and remove by turning spud counter-clockwise

and lifting it out. Replace the L.P. gas spud with

the appropriate Natural gas spud shown in the

table.

Continue to replace the remaining orifice spuds,

one at a time. Place the L.P. gas spuds in plastic

parts bag for future use and keep with literature

package. Replace burners caps using both

screws, and burner grates.

Surface

Rate

Orifice

Color

burner

(BTU/hr)

Number

Marking

Left rear

8,000

N139

Blue/Black

Left front

9,500

N150

Blue/Brass

Right front

9,500

N150

Blue/Brass

Right rear

5,000

N110

Blue/White

Natural Gas

cap

washer

Nat. gas

L.P. gas

pressure

regulator

orifice

number

5/16"

nut driver

orifice spud.

Replace orifice

spud with the

number listed

in chart.

burner

assembly

Locate the L.P. gas orifice spuds in

literature package. Orifice spuds are

stamped with a number and

marked with two color dots.

Natural gas

orifice spud

3.

Surface

Burners:

Remove burner

caps. Use a

Phillips or

Quadrex

screwdriver to

remove the two

screws holding

the burner head down. Lift the

burner head off the cooktop to uncover the

orifice spud holder. The orifice spud is recessed

in the holder.

Note: Reinstall one of the screws through the

range cooktop to hold orifice spud holder in place

while removing and replacing orifice spuds.

reinstall

one of the

screws

orifice

spud

orifice

spud

holder

spark electrode

range cooktop

L.P.

pressure

regulator

Natural

plastic

cover

plastic

cover