7-1

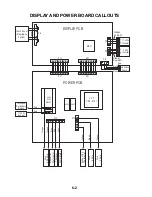

WIRING DIAGRAMS & STRIP CIRCUITS

SCHEMATIC DIAGRAM

MAGNETRON

CF

TT

1

BR16

8

OR16

10 BR22

13

W22

12

Y22

29

R16

25

BL22

28

W22

5P1

1

26

BL22

NFS

L1

Door

TT

4901

W20

R20

B20

33

W16

32

BL16

INTERLOCK

SECONDAR

Y

DISPLA

Y

PCB

&

POWER

PCB

INTERLOCK

PRIMAR

Y

INTERLOCK

MONIT

OR

P2/P3/P5/P12/P14/CN1/CN151/CN152/CN153/CN701/

CN702/CN703:

WIRE

T

O

PCB

CONNECT

ORS

4906

SM

HF

Magnetron

Thermostat

HF

9Y

16

27

B22

34 R22

31

BL22

40 W18

39 W18

Motor

Capacitor

P12

Exhaust

Fan

Thermostat

L.V

.T

.

Prim.

Sec.

HUMIDITY

SENSOR

1

B

R

W

9Y

1

6

7103

TR1-5101

SM

N1

19

BL22

17

B22

CN702

1

100W

INVER

TER

1

1

CL

TR22

23

W22

R 24

1P1

1

B 24

CN701

1

P3

P14

1P10

2P10

3P10

1

Fuse

20 Amp

15

R22

1

14

W22

35

GR22

P0/P10/P1

1:

WIRE

T

O

WIRE

CONNECT

ORS

1

HL

1

HL

HL

21 W22

22 Y22

2P1

1

50

GR16

41 Y/G18

43 Y/G18

GND

42 Y/G18

CN1

CN152

CN151

P5

1

P2

4903

MW

Relay

50

GR16

1

2

1

CN153

CL

CN703

E701

45

26A

WG/4C

46

26A

WG/3C

SYMBOL

NOTES

CONDITION:

DOOR

OPEN

CF

TT

CA

VITY

LAMP

D.C.

COOLING

FA

N

MOT

OR

TURNT

ABLE

MOT

OR

CL

B:

BLACK

BL:

BLUE

R:

RED

W

:

WHITE

G:

GREEN

Y

:

YELLOW

BR:

BROWN

OR:

ORANGE

HF

HOOD

EXHAUST

F

AN

MOT

OR

SM

STIRRER

MOT

OR

HOOD

LAMP

(COOKT

OP

LAMP)

HL

GR:

GRA

Y

P:

PINK

18

BL16

TR:

TRANSP

ARENT

36

B22

7R

2

2

36

B22

37

R16

49

GR22

Filter

Capacitor

38 R22

1

BR16

WIRE

SIZE

-

A

WG16

WIRE

COLOR

-

BROWN

WIRE

NO.

-

1

DWG.

NO.

MU-063

Rev

.

B

40W

INVER

TER

24

W22

Y22

Y22

TR22

26A

WG/3C(4C):

RIBBON

CABLE/3C(4C)

20

R22

L

E

N

1P0

2P0

2 BL16

G

Cavity

Thermostat-1

3 BL16

B

W

120V

/60Hz

Cavity

Thermostat-2

4 BL16

Cavity

Thermostat-3

16

G22

52

BR22

Fuse

4 Amp

30 OR22

53 OR22

Fuse

0.25

Amp

Fuse

51 G22

4

Amp

1

1

BR22