4-1

DIAGNOSIS & TROUBLESHOOTING

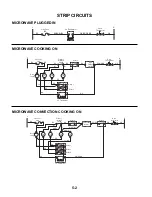

TOUCH PANEL CONTINUITY TEST

1. Remove the electronic oven control from

the microwave oven (see page 2-3 for the

procedure).

2. Set the ohmmeter to the R x 1 scale.

3. Refer to the “Touch Panel Continuity Dia-

gram,” and touch the ohmmeter leads to the

indicated conducting paths on the “Flex

Circuit Connector Diagram.” Press the key-

pad indicated in the chart for the circuit

under test. The meter should indicate con-

tinuity if the switch is working properly.

MICROWAVE OVEN

POWER OUTPUT TEST

The power output of the magnetron can be

measured by the following test: (for accurate

results, the line voltage must be 120 VAC and

the oven cavity must be clean).

1. Fill a glass measuring cup with one cup

(250 ml) of “lukewarm” (68˚F / 20˚C) to

(77˚F / 25˚C) tap water.

2. Place the cup of water in the center of the

oven.

3. Operate the microwave oven at HIGH

power.

4. The water should boil within 3-1/2 to 4

minutes.

NOTE: Times longer than 4 minutes may indi-

cate that the operating voltage is lower than

110 volts, or that there is a problem with the

oven.

SENSOR

POPCORN

SENSOR

REHEAT

SENSOR

COOK

WARM

HOLD

TIMER

SET/OFF

CLOCK

SET

DEFROST

OPTIONS

N.C.

N.C.

N.C.

N.C.

N.C.

N.C.

N.C.

N.C.

N.C.

N.C.

N.C.

N.C.

N.C.

N.C.

N.C.

HOUR

UP

HOUR

DOWN

MINUTE

UP

MINUTE

DOWN

SECOND

UP

SECOND

DOWN

OFF/

CANCEL

JET START

/ENTER

MEAT

POULTRY

FISH

BAKED

GOODS

SNACK

FOODS

OTHER

FOODS

CONVECT

COMBI.

TEMP/POWER

UP

TEMP/POWER

DOWN

MICRO

1

8

9

10

11

12

13

2

3

4

5

6

7

Touch Panel Continuity Diagram

1

2

3

4

5

6

7

8

9

10

11

12

13

Flex Circuit Connector Diagram

Sensor

Connector

Relay 4

Relay 7

Relay 8

Relay 1

Buzzer

Relay 2

Low Voltage

Transformer

9-Pin Connector

13-Pin Flex

Connector

Electronic Oven Control Board Layout

Summary of Contents for GM8155XJB

Page 34: ...2 22 NOTES ...

Page 42: ...3 8 NOTES ...

Page 48: ...5 4 NOTES ...

Page 51: ...CORPORATION ...