v

Turntable Motor ................................................................................................................. 5-3

Humidity Sensor ............................................................................................................... 5-4

Hood Exhaust Fan Motor .................................................................................................. 5-4

AC Line Filter .................................................................................................................... 5-5

Thermostats ...................................................................................................................... 5-5

DIAGNOSIS & TROUBLESHOOTING ..................................................................................... 6-1

Interlock Switch Checkout Procedures ............................................................................. 6-1

Touch Panel and Electronic Control Test .......................................................................... 6-2

Microwave Oven Power Output Test ................................................................................ 6-3

Failure Codes Indications ................................................................................................. 6-3

WIRING DIAGRAm & STRIP CIRCUITS .................................................................................. 7-1

Wiring Diagram - 8205889 - Sensor Model ...................................................................... 7-1

Wiring Diagram - 8205660 - Non Sensor Model ............................................................... 7-2

Strip Circuits ..................................................................................................................... 7-3

Microwave Cooking ..................................................................................................... 7-3

Hood Exhaust Fan On High Automatically .................................................................. 7-3

Hood Exhaust Fan On Low Speed.............................................................................. 7-3

Hood Exhaust Fan On High / Medium ........................................................................ 7-4

Microwave Oven Plugged In—Time of Day Displayed ............................................... 7-4

Door Open—Oven Cavity Light Is On ......................................................................... 7-4

Cooktop Light On High ................................................................................................ 7-4

Cooktop Light On Low (Night Light) ............................................................................ 7-4

TABLE OF CONTENTS - CONTINUED

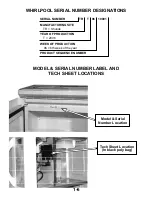

Summary of Contents for KM-30 8178573

Page 1: ... MICROWAVE OVEN HOOD COMBINATION KM 30 8178573 ...

Page 16: ...2 2 NOTES ...

Page 44: ...5 6 NOTES ...

Page 48: ...6 4 NOTES ...

Page 54: ......