- 9 -

Installation and Connection

Electrical connection/survey of supply lines

The electrical connection must be carried out by an authorised electrician in accordance with

existing rules and regulations.

The wiring diagram is located in the motor compartment.

The terminal for the electrical connection is located behind the right side plate.

An approved plug outlet or a safety cutout must be located close to the oven so that

the oven can be disconnected during installation and repair. The safety cutout must be

able to cut off all poles with a total distance of break of at least 3 mm. Each of the two

units in a stacked arrangement (CombiPlus) must have its own plug outlet or safety cut-

out.

The warranty does not cover incorrect connection.

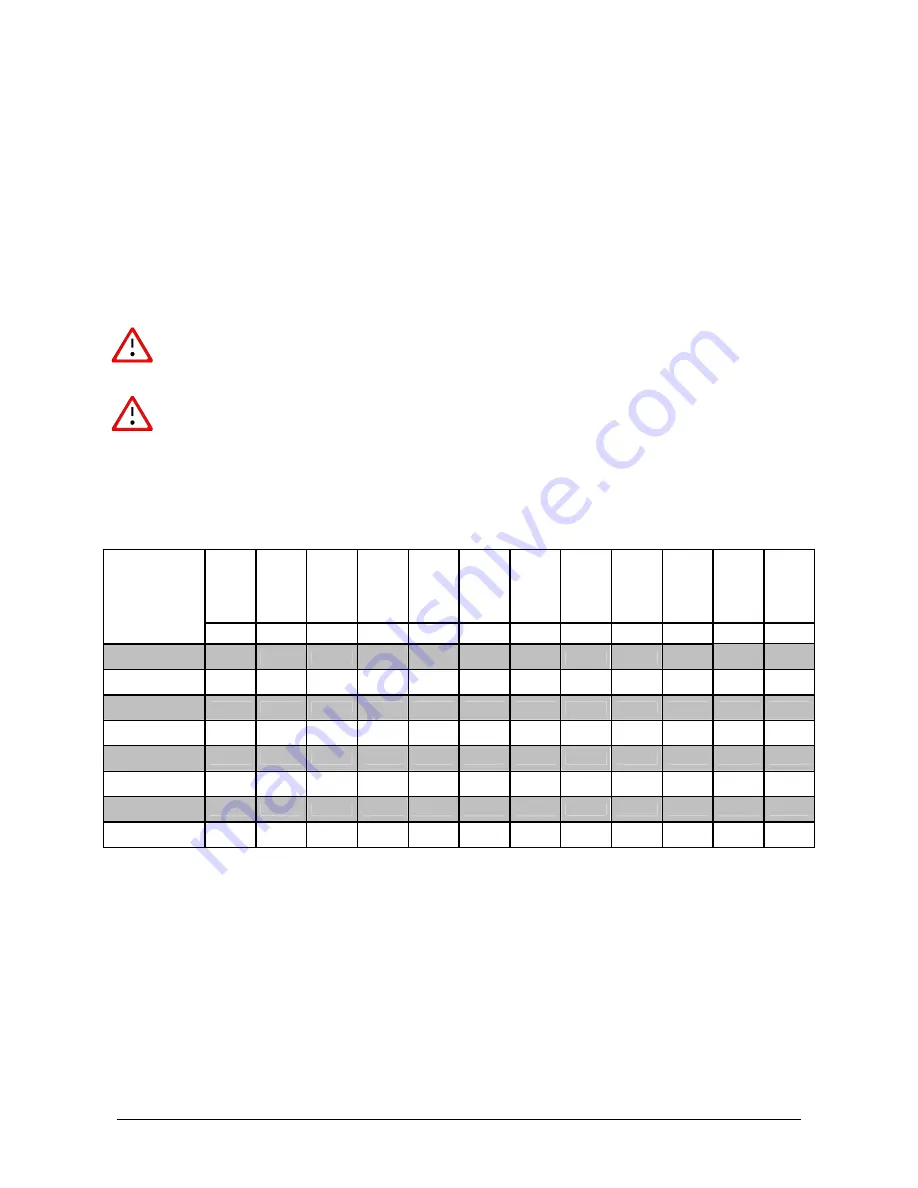

Supply lines - survey (applies to all electric models )

(All cross sections in mm² )

382,

395

382,

395

AFO ----

Æ

375,

388

375,

388

376,

377,

378,

389,

390,

391

376,

377,

378,

389,

390,

391

379,

392

379,

392

380,

393

380,

393

383,

396

383,

396

384,

397

384,

397

9

kW Fuse 18

kW Fuse 24

kW Fuse 36

kW Fuse 27

kW Fuse 60

kW Fuse

400V 3N ~ 50/60

Hz

5x2,5

16A

5x4

35A

5x10

50A

5x10

63A

5x10

50A

5x25

100A

400V 3 ~ 50/60

Hz

4x2,5 16A 4x4 35A 4x10 50A 4x10 63A 4x10 50A *

*

415V 3N ~ 50/60

Hz

5x2,5

16A

5x4

25A

5x10

50A

5x10

50A

5x10

50A

5x25

100A

440V 3 ~ 50/60

Hz

4x2,5 16A 4x4 25A 4x10 50A 4x10 50A 4x6 35A *

*

200V 3 ~ 50/60

Hz

4x4

35A

4x16

63A

4x25

100A

4x35

125A

4x25

80A

*

*

230V 3 ~ 50/60

Hz

4x4 25A 4x10 50A 4x25 80A 4x35 100A 4x25 80A *

*

480V 3 ~ 50/60

Hz

4x2,5

16A

4x4

25A

4x6

35A

4x10

50A

4x6

35A

*

*

208V 3 ~ 50/60

Hz

4x4 25A 4x10 50A 4x25 80A 4x35 100A 4x25 80A *

*

* Not possible

Recommended supply line: H07RN-F

When you connect the oven, you should

•

Follow the installation instructions and the information given on the rating plate.

•

Comply with local rules and regulations.

•

WHIRLPOOL recommends the use of a (Type B) RCD/RCCB. 300 mA