4-16

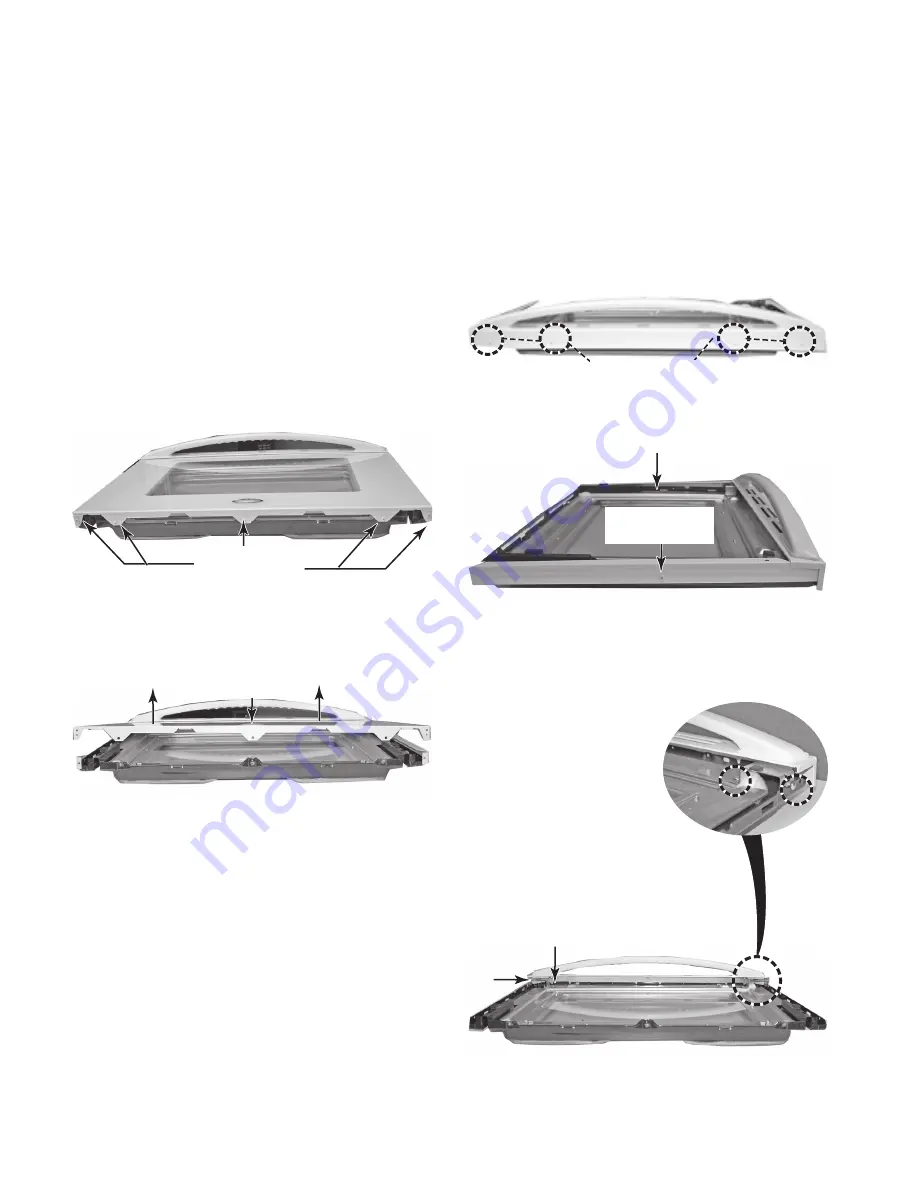

REMOVING THE DECORATIVE GLASS, OVEN DOOR

HANDLE AND THE OVEN DOOR GLASS

1. Remove oven door (see removing and

reinstalling the oven door page 4-14 for

procedure).

2. Place the oven door on a padded work

surface with decorative glass and handle

facing up and the bottom edge facing the

front.

3.

To remove the decorative glass:

a) Remove five screws from bottom glass

retainer on bottom edge of door.

Glass Retainer

Screws

b) Lift the decorative glass up with glass

retainer and slide back from under

handle to remove.

Decorative

Glass

c) Remove glass retainer from glass by

sliding it off bottom of glass.

4.

To remove oven door handle:

a) Remove the decorative glass (see

step 3).

b) Remove four screws from top of oven

door trim.

c) Remove two side oven trim screws from

right and left trim pieces.

Oven Door Top

Trim Screws

Oven Door Side

Trim Screws

d) Remove four screws holding oven door

handle support to oven door liner.

Oven Door Handle

Support Screws

Summary of Contents for RY160LXTQ

Page 26: ...2 18 NOTES ...

Page 52: ...5 6 NOTES ...

Page 58: ...6 6 NOTES ...

Page 59: ...7 1 WIRING DIAGRAMS ...

Page 60: ...7 2 ...

Page 62: ......