6

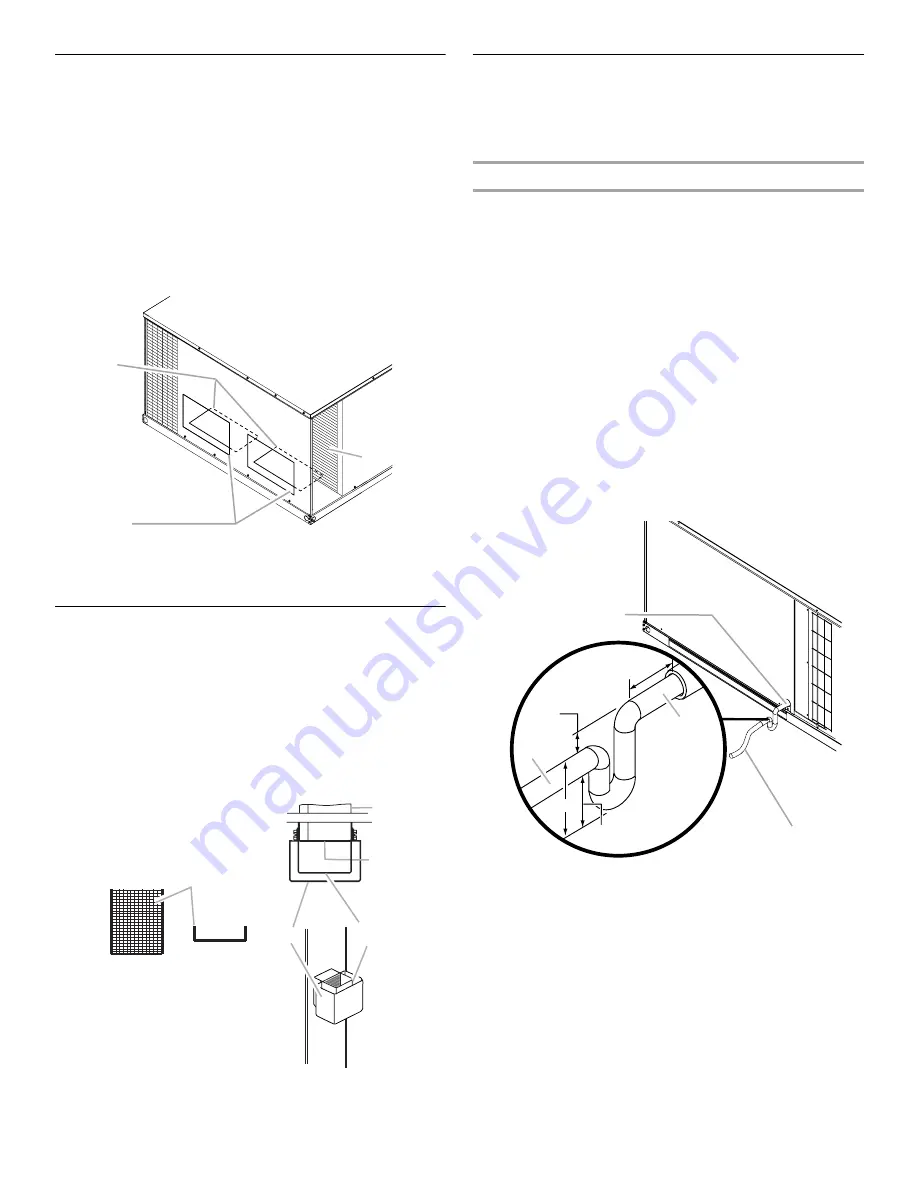

Convert to Downflow

This furnace is factory-built for horizontal airflow applications and

may also be field-converted for downflow use.

To convert to downflow use:

1. Remove the filter access panel.

2. Remove the two downflow duct cover plates (one screw and

tab for each) found in the return and supply air

compartments.

3. Using eight #10 x

³⁄₄

" screws (field supplied), install the

previously removed duct covers on the horizontal return and

supply air openings. Use the pilot holes provided.

4. Reinstall the filter access panel.

Exhaust Vent Assembly

1. Place the screen over the exhaust port.

2. Place the internal vent hood over the exhaust port.

3. Place the outer cover over the internal vent hood and exhaust

port.

4. Align the screw holes in the covers with the holes in the

exhaust port.

5. Attach the covers using the four #10 screws provided.

Connect Condensate Drain

The condensate drain outlet is a

³⁄₄

" threaded PVC fitting located

at the bottom on the side of the furnace. A

³⁄₄

" drain line with trap

must be installed on all applications to avoid accumulation of

condensate under or around the furnace.

Install Condensate Trap

1. Construct the condensate trap from PVC tubing as shown in

“Condensate Trap Construction.”

NOTES:

■

The condensate trap allows a standing column of water of

at least 2" (50 mm).

■

The top of the drain trap inlet must be at least least 1"

(25 mm) above the top of the drain trap outlet.

■

The trap should be installed as close to the furnace as

possible, while still providing proper drainage.

■

For service access, do not block heat exchanger access

panel or the filter access panel with the drain line.

2. Thread the drain assembly into the

³⁄₄

" PVC fitting.

NOTE: Do not glue the threaded fitting so it can be removed

during servicing of unit.

3. Run the drain line to an open drain or other suitable disposal

point.

Condensate Trap Construction

A. Filter access panel

B. Horizontal return and supply air openings

C. Downflow duct cover plates

A. Screen

B. Exhaust port

C. Internal vent hood—slotted side

faces condenser coil

D. Outer cover

C

B

A

To p View

C

F ront View

B

A

A

D

Preformed

A.

³⁄₄

" PVC fitting (threaded) drain condensate connection

B.

³⁄₄

" drain pipes, field provided

C. Drain trap outlet

D. Drain trap inlet

A

B

1" Min.

12" Max.

2" Min.

3" Min.

C

D