This document is only intended for qualified technicians who are aware of the respective safety regulations.

Revised on 07/01/2003

Subject to modification

Document No. WOI/WM/2003/001

The timing sequences of this individual cycle are enclosed for your ready reference.

OPERATING INSTRUCTIONS:

1. Add detergent and load the clothes as usual.

2. Connect the Fill Hose and Power cord to the appropriate points. 3. Place the Drain Hose on the ground.

4. Switch on the machine. Set the Water level and Water inlet Selector (as applicable) to the desired settings.

5. Select the appropriate Course and Program.

6. Press the Start button to commence the operation.

7. At the completion of the cycle, the user will get a intermittent beep sound lasting for 20 seconds. STATUS

INDICATORS

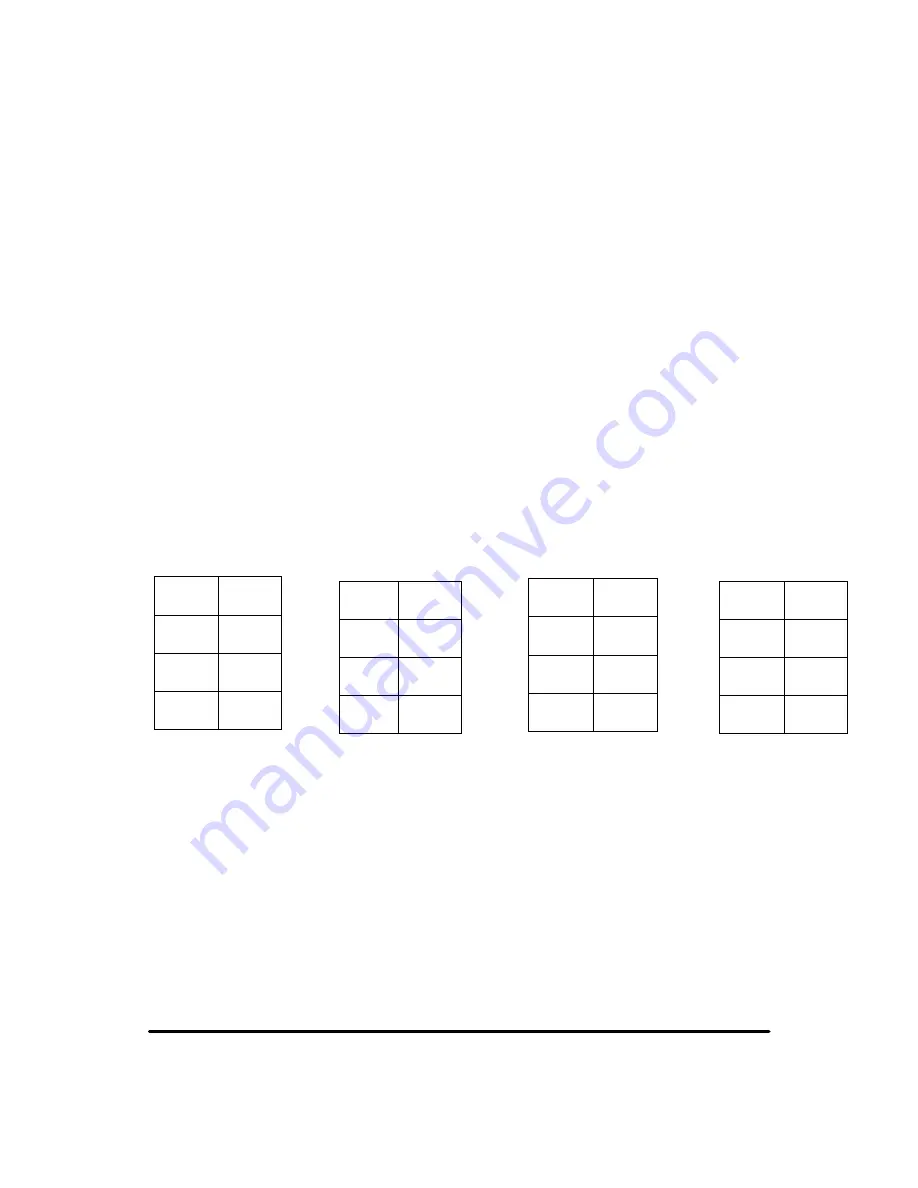

As you are aware, LED indicators are provided in the Control Panel to indicate the status of the wash cycle. Whenever the

Program and Course is selected, the corresponding LED indicators will glow. Once the operation is commenced, the LED

corresponding to the first operation (Soak or Wash or Rinse or Spin) will blink indicating that the particular process is on.

Once the process is completed, the corresponding LED will go off and the LED corresponding to the next operation will

start blinking. Thus by a look at the Control Panel, the user can come to know of the process in progress (indicated by the

blinking LED) and the pending processes for the completion (indicated by glowing LED/s) of the cycle. Let us take an

example of a cycle wherein WASH, RINSE & SPIN is selected. The sequence of LED display will be as follows:

1.At the time of setting 2.During Washing 3.At the time of setting 4.During Washing

SPECIAL FEATURES IN ET MODES:

• DOUBLE RINSE FACILITY IN HEAVY WASH PROGRAME

Whenever the user chooses Heavy Program, after washing the clothes the machine takes in water twice for rinsing. This is

to increase the effectiveness of rinsing. However, it is worth noting here that no SIS and Spin is provided before the first

rinse. This has been thoughtfully designed such that the liquid blue from the dispenser gets dispensed only after the second

rinsing is completed.

• DYNAMIC SOAK:

Whenever the user selects SOAK in the wash cycle, during this soaking period the machine alternatively stirs (agitates) for

sometime and soaks for sometime. This aids better mixing of detergent in the water thereby aiding dirt removal. The total

OFF

SOAK

ON

WASH

ON

RINSE

ON

SPIN

OFF

SOAK

BLINK

WASH

ON

RINSE

ON

RINSE

OFF

SOAK

ON

WASH

BLINK

RINSE

ON

SPIN

OFF

SOAK

OFF

WASH

OFF

SPIN

BLINK

SPIN