01/09

FOR SERVICE TECHNICIAN’S USE ONLY

PART NO. W10198666B

TECH SHEET - DO NOT DISCARD

PAGE 12

P8-2

GND

L1 LINE – BK

BK

LBU

P8-4

P8-3

P9-1

P8-5

DOOR

NEUTRAL

MOTOR

MTR CS

MOIST.

MOIST RTN

MODEL

MODEL RTN

P14-5

P14-3

P14-6

R-W

R-W

BK-W

HEATER RELAY 1

V

HEATER RTN

N.O.

COM

BK

P9-2

BK

L1

W

W – NEUTRAL N

T

W

5M

6M

3M

BU

BELT

SWITCH

MAIN

3.3–3.6

START

2.7–3.0

OUTLET THERMISTOR

10 k

2M

1M

R

R-W

TF2

NC

1V

2

1

IG

IGR

50–500

3

4

FS1

FS2

VALVE

MOV

HOLD

ASSIST

MAIN

IGNITOR

VALVE

NO. 1

VALVE

NO. 2

FLAME SENSOR

P2-1 VDD

P2-2 DATA

P2-3 VSS

THERMAL FUSE

196°F (91°C)

BK

(0.25 TERMINAL)

R

R

G-Y

P14-1

P14-2

N.C.

N.C.

LBU

120 VOLTS

4M

DRIVE MOTOR

1/3 H.P.

DOOR

SWITCH

G-Y

Y-R

P13-1

P13-2

P14-4

Y-R

SENSOR

G-Y

SENSOR MOVS

Y-R

BK

TEMP.

TEMP RTN

THERMAL

CUT-OFF

352°F (178°C)

MACHINE

CONTROL

ELECTRONICS

NC

NO

W

BU

LBU

TF1

(0.25 TERMINAL)

CONSOLE

ELECTRONICS

P005-3 VDD

P005-2 DATA

P005-1 VSS

SERIAL

COM

BK

R

HIGH LIMIT

THERMOSTAT

255°F (124°C)

P8-2

GND

R

CENTRIFUGAL

SWITCH

2M

1M

5M

6M

3M

R – LINE L2

W

DOOR

SWITCH

W – NEUTRAL N

T

LBU

LBU

W

P8-4

P8-3

P9-1

P8-5

BK-W

THERMAL FUSE

196°F (91°C)

4M

DRIVE MOTOR

1/3 H.P.

MAIN

3.3–3.6

START

2.7–3.0

SENSOR

DOOR

NEUTRAL

MOTOR

MTR CS

MOIST.

MOIST RTN

MODEL

MODEL RTN

OUTLET TEMP.

OUTLET

TEMP. RTN

MACHINE

CONTROL

ELECTRONICS

Y-R

P13-1

P13-2

P4-4

P4-5

P4-3

P4-6

R

OUTLET THERMISTOR

10 k

P9-2

L1

BR

L1 LINE – BK

V

HEATER RTN

N.O.

COM

BK

BK

BK

R

R-W

NC

HIGH LIMIT

THERMOSTAT

295°F (146°C)

THERMAL CUT-OFF

352°F (178°C)

HEATER

7.8–11.8

DRUM LAMP

G-Y

P4-2

INLET

TEMP. RTN

R

240 VOLTS

120 VOLTS

P2-1 VDD

P2-2 DATA

P2-3 VSS

CONSOLE

ELECTRONICS

BELT

SWITCH

HEATER RELAY 1

G-Y

G-Y

SENSOR MOVS

Y-R

Y-R

BK

W

P8-1

SERIAL

COM

INLET TEMP.

P4-1

R

R

R

BU

NC

NO

INLET THERMISTOR

50 k

COMBINED PART

R-W

W

(0.25 TERMINAL)

(0.25 TERMINAL)

P005-3 VDD

P005-2 DATA

P005-1 VSS

R

NEUTRAL

TERMINAL

LINKED TO

CABINET

LAMP LOAD

5

BR

BK

DRUM LAMP

P8-1

CENTRIFUGAL

SWITCH

LBU

+5 V

Gnd

N.C.

P003-1

P003-2

P003-3

P5-1 VDD

P5-5 DATA OUT

P5-8 12 VDC

P5-2 DATA IN

P5-3 VSS

P5-4 STROBE

P5-6 CLOCK

P5-7 BUZZER

+5 V

Gnd

N.C.

P003-1

P003-2

P003-3

P5-1 VDD

P5-5 DATA OUT

P5-8 12 VDC

P5-2 DATA IN

P5-3 VSS

P5-4 STROBE

P5-6 CLOCK

P5-7 BUZZER

5400 W

FILTER

MOV

BK

W

BK

W

LAMP LOAD

FILTER

MOV

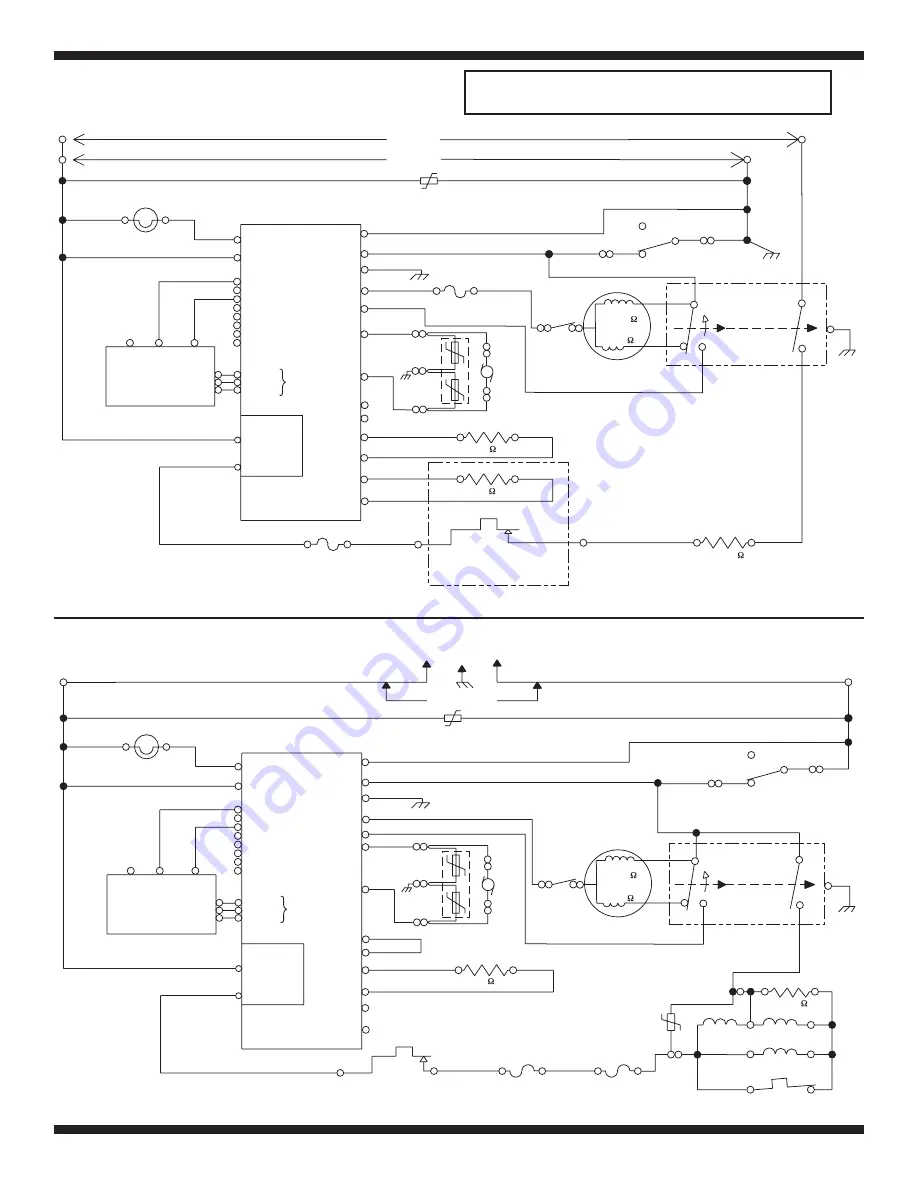

ELECTRIC DRYER WIRING DIAGRAM

IMPORTANT:

Electrostatic (static electricity) discharge may cause

damage to machine control electronics. See page 1 for details.

GAS DRYER WIRING DIAGRAM

LBU