80% GAS FURNACE INSTALLATION INSTRUCTIONS

GAS FURNACE SAFETY

Table of Contents

GAS FURNACE SAFETY................................................................1

INSTALLATION REQUIREMENTS ................................................3

Tools and Parts ............................................................................3

Location Requirements ................................................................4

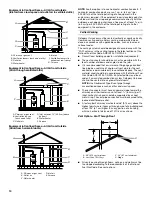

Installation Configurations ...........................................................5

Ductwork Requirements ..............................................................7

Electrical Requirements ...............................................................7

Gas Supply Requirements ...........................................................7

Venting Requirements..................................................................7

INSTALLATION INSTRUCTIONS ..................................................9

Inspect Shipment .........................................................................9

Plan Vent System .........................................................................9

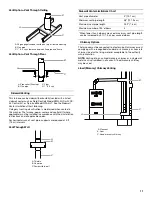

Determine Vent Pipe Direction...................................................12

Connect Venting.........................................................................14

Install Duct Work ........................................................................14

Filter Specifications ....................................................................14

Make Electrical Connections .....................................................15

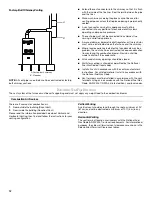

Make Gas Connections..............................................................16

Check the Furnace Input Rate (if required) ................................17

Adjust the Furnace Input Rate (if required) ................................17

Complete Installation..................................................................18

Shut Down..................................................................................19

SEQUENCE OF OPERATION ......................................................19

Heating .......................................................................................19

Fan On ........................................................................................19

Cooling .......................................................................................20

CONTROLS ...................................................................................20

TROUBLESHOOTING ..................................................................21

ASSISTANCE OR SERVICE .........................................................24

Accessories ................................................................................24

46924B008

Whirlpool

®

Home Cooling and Heating

14610 Breakers Drive

Jacksonville, FL 32258

Whirlpool

®

Models

WFAU, WFAR, WFAT

,

WFLU, WFLR, WFLT

You can be killed or seriously injured if you don't immediately

You

can be killed or seriously injured if you don't follow

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING.”

These words mean:

follow instructions.

instructions.

DANGER

WARNING