5

Installation Configurations

WGFDU and WFCU models must be installed only as upflow

furnaces.

WGFDC and WFCC models must be installed only as

counterflow (downflow) furnaces.

IMPORTANT: To ensure access to parts for servicing, install

upflow and counterflow furnaces so that the burner and blower

access panels are readily accessible.

Upflow Installations

Furnaces can be installed with either a side or bottom air return.

For bottom air return the bottom air return knockout plate must

be removed. For furnaces that do not include a side or bottom

return filter rack, kit no. AFILT524-1 (side return) or kit no.

AFILT529-1 (bottom return) can be used.

To provide sufficient filter area for installations requiring more

than 1,600 CFM nominal air delivery, return air will have to be

brought through both sides of the furnace, or through one side

and the bottom.

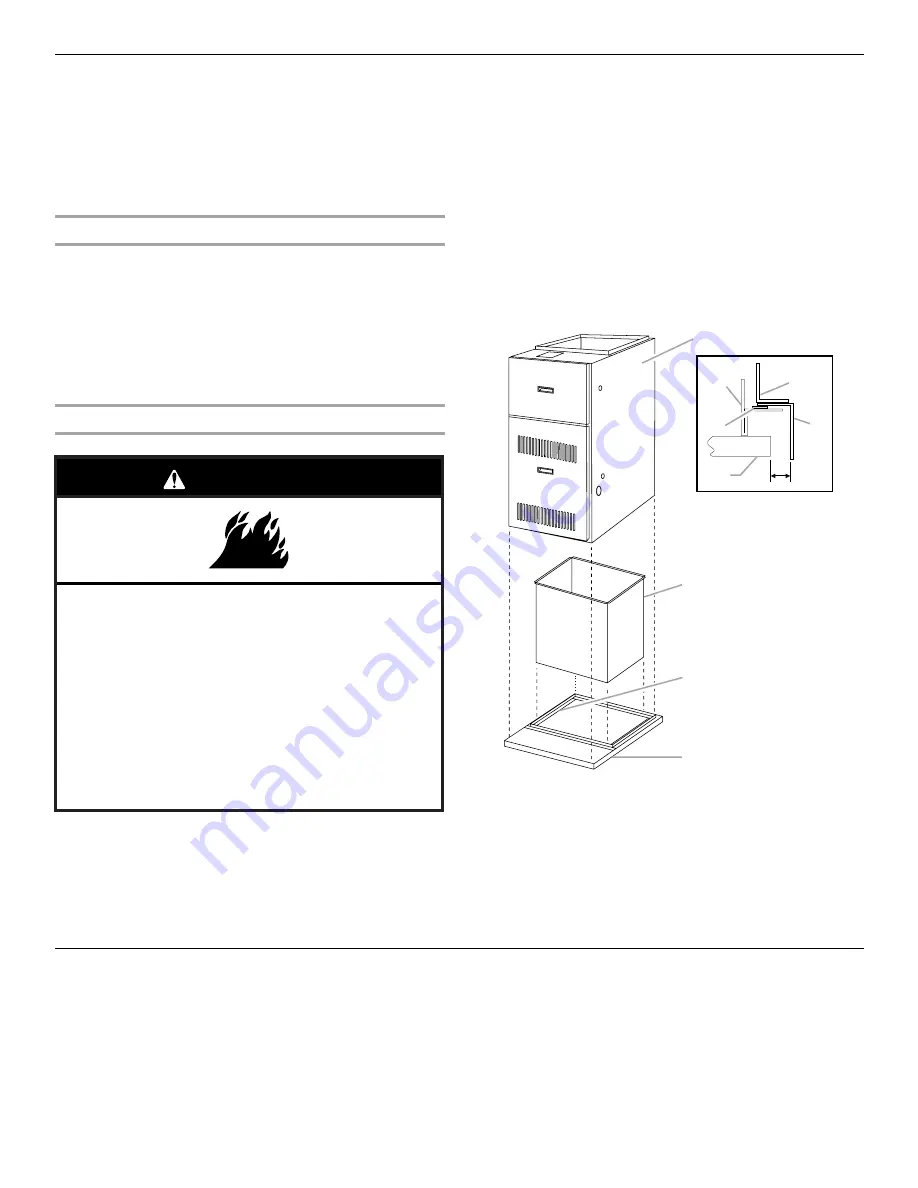

Installation for Counterflow (Downflow) Models

IMPORTANT:

■

The furnace may be installed directly on the supply plenum or

coil cabinet if the furnace is installed on a noncombustible

floor.

■

For installations on combustible flooring, a special base must

be ordered and used. See the “Accessories” section.

1. Cut a hole in the floor, sized to provide 1" (2.5 cm) clearance

between all 4 sides of the duct and the edge of the flooring.

The 4 angles on the base assembly should be recessed into

the floor joists, and the base should rest on all 4 outside

flanges.

2. Construct duct connections with 1" to 1

³⁄₄

" (2.5 cm to 4.4 cm)

right angle flanges, and long enough to extend below the

floor joists.

3. Drop the duct connections through the top of the base

assembly with the right angle flanges in good contact with

the glass tape on top of the base assembly.

4. Position the furnace over the right angle duct flanges.

Combustible Floor Installation (Counterflow Models only)

Filters

If a filter other than the one supplied by the furnace manufacturer

is used, see Minimum Filter Requirements in “Filter

Specifications.”

Ductwork Requirements

■

Install all conditioned air plenums, ducts and air filters (if not

provided on the furnace) in accordance with NFPA 90B

Standard for the Installation of Warm Air Heating and Air-

Conditioning Systems (latest edition).

■

The furnace is provided with flanges for the connection of the

plenum and ducts.

■

All air filters must be listed as Class 2 furnace air filters.

■

All ductwork must be made of materials and insulated to

meet local, state and national codes. Ductwork installed

outdoors must be sealed, weatherproofed and protected

against physical damage. Caulking, flashing or other means

of adequately providing a permanent weather seal should be

used where duct penetrates a building or structure opening.

WARNING

Fire Hazard

Before installing counterflow (downflow) furnace on

combustible surface, such as wood, install one of the

following kits:

WABASE 511 (14.5" cabinets)

WABASE 512 (17.5" cabinets)

WABASE 568 (21" cabinets)

WABASE 569 (24.5" cabinets)

Contact your local dealer.

Failure to do so can result in death or fire.

A. Base assembly

B. Furnace

C. Outlet duct (drops into base

assembly)

D. Combustible floor

E. Woven glass tape (between

flanges of outlet duct and

base assembly)

1"

A

B

C

D

E

C

E

A

B