23

Pipe-joint compounds suitable for use with Natural and LP

gas must be used. Do not use Teflon

®

tape.

6. Turn off the gas supply at the manual gas shutoff valve.

7. Remove the inlet pressure tap plug on the gas control valve

and connect pressure gauge to the

¹⁄₈

" NPT inlet

pressure tap.

8. Turn on the gas supply at the manual gas shutoff valve.

9. Observe the inlet pressure.

The minimum inlet gas supply pressure is 5" (12.7 cm) W.C.

for Natural gas and 11" (27.9 cm) W.C. for propane gas.

The maximum inlet gas supply pressure is 10

¹⁄₂

" (26.7 cm)

W.C. for Natural gas and 13" (33 cm) W.C. for propane gas.

10. Turn off the gas supply at the manual gas shutoff valve.

IMPORTANT: If the inlet gas supply pressure is not within the

minimum and maximum range as shown on the rating plate,

contact your gas supplier.

11. Disconnect the pressure gauge from the

¹⁄₈

" (3.2 mm) NPT

inlet pressure tap.

12. Replace the inlet pressure tap plug on the gas control valve.

13. Turn on the gas supply at the manual gas shutoff valve.

14. Test all connections by brushing on an approved

noncorrosive leak-detection solution. Bubbles will show a

leak. Correct any leak found.

■

At test pressures greater than

¹⁄₂

psig (3.5 kPa), the

furnace and the manual gas shutoff valve must be

disconnected from the gas supply piping system.

■

At test pressures less than or equal to

¹⁄₂

psig (3.5 kPa),

the furnace must be isolated from the gas supply piping

system by closing the manual gas shutoff valve.

15. Replace the burner access door.

Check the Furnace Input Rate

(if required)

IMPORTANT:

■

The furnace input rate must not exceed the input rating on

the furnace rating plate.

■

This furnace is equipped for rated input at manifold pressures

of 3

¹⁄₂

" (8.9 cm) W.C. for natural gas and 10" (25.4 cm) W.C.

for propane gas.

■

For natural gas, check the furnace rate by observing the gas

meter, making sure all other gas appliances are turned off.

The test hand on the meter should be timed for at least one

revolution.

■

At altitudes from 2,000 to 7,500 ft (609.6 m to 2,286 m) the

furnace input rate must not exceed that on the rating plate.

NOTE: The actual heating value of your gas can be obtained from

your local utility company. Typical values are shown in the

Manifold Pressure vs. Altitude Chart in “Adjust the Furnace Input

Rate.”

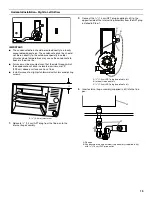

Adjust the Furnace Input Rate

(if required)

For Altitudes 4,500 to 7,500 ft (1,371.6 m to 2,286 m)

Above Sea Level

1. Remove the burner access door.

2. Move the gas control to the OFF position. Use only your hand

to move the gas control; tools are not required.

3. Remove the outlet pressure tap plug on the gas control valve

and connect pressure gauge to the

¹⁄₈

" (3.2 mm) NPT outlet

pressure tap.

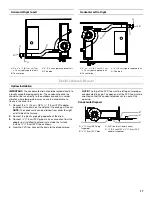

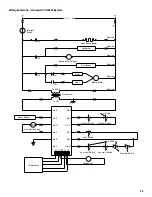

Gas Control Valve

A.

¹⁄₈

" (3.2 mm) NPT plugged tap

B. Manual gas shutoff valve

C. Ground joint union

D. Tee

E. Sediment trap

F. Cap

G. Gas control valve

(inside furnace)

A. Closed valve

B. Open valve

®Teflon is a registered trademark of E.I. Dupont de Nemours and

Company.

B

C

D

E

F

G

A

WARNING

FIRE OR EXPLOSION HAZARD

Failure to follow the safety warnings exactly could result

in serious injury, death or property damage.

Never test for gas leaks with an open flame. Use a

commercially available soap solution made specifically

for the detection of leaks to check all connections. A fire

or explosion may result causing property damage,

personal injury or loss of life.

A

B

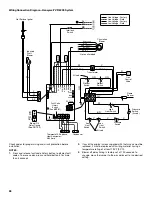

Btu/h

Input

=

Cu. ft per Revolution

x 3600 x Heating

Value

# Seconds per Revolution

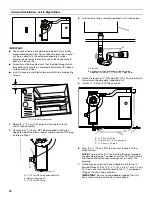

A. Gas control

B. Alternate gas control switch

C.

¹⁄₈

" (3.2 mm) NPT inlet

pressure tap

D.

¹⁄₂

" (1.3 cm) NPT inlet

E. Regulator adjusting burner box

reference tap

F.

¹⁄₈

" (3.2 mm) NPT outlet

pressure tap

G.

¹⁄₂

" (1.3 cm) NPT outlet

OFF

ON

A

F

C

E

D

G

B

Summary of Contents for WFCT

Page 31: ...31 Notes ...