10

Vertical Venting

Category I furnaces must be vented vertically or nearly vertically.

Common venting and multistory venting are permitted when

done in accordance with applicable codes, such as local and

national codes.

The venting system should be designed in accordance with the

“FAN” columns in the venting tables in the latest editions of the

National Fuel Gas Code, ANSI Z223.1/NFPA 54.

■

Consult local building codes for installation requirements.

■

The vent connector should be as short as possible with the

least number of elbows and angles to do the job.

■

It is recommended that a minimum of 26 gauge galvanized

flue pipe be used. Use of single-wall vent pipe for the vent

connector is permissible only in conditioned space. The vent

material used should be in accordance with the National Fuel

Gas Code, ANSI Z223.1/NFPA 54 (latest edition) and local

codes. Fan-assisted combustion system Category I furnaces

shall not be vented into single wall metal vents.

NOTE: Use Doublewall Type B vent pipe through

unconditioned space such as attics and crawl spaces.

■

The vent connector must have an upward slope toward the

chimney on all horizontal runs of at least

¹⁄₄

" per ft of

horizontal run and should be supported by a sheet metal

strap. The vent pipe connection must be secured to the

induced draft blower outlet.

■

All vents passing through floors, ceilings, and walls must be

fire stopped according to the requirements of the National

Fuel Gas Code. See vent options.

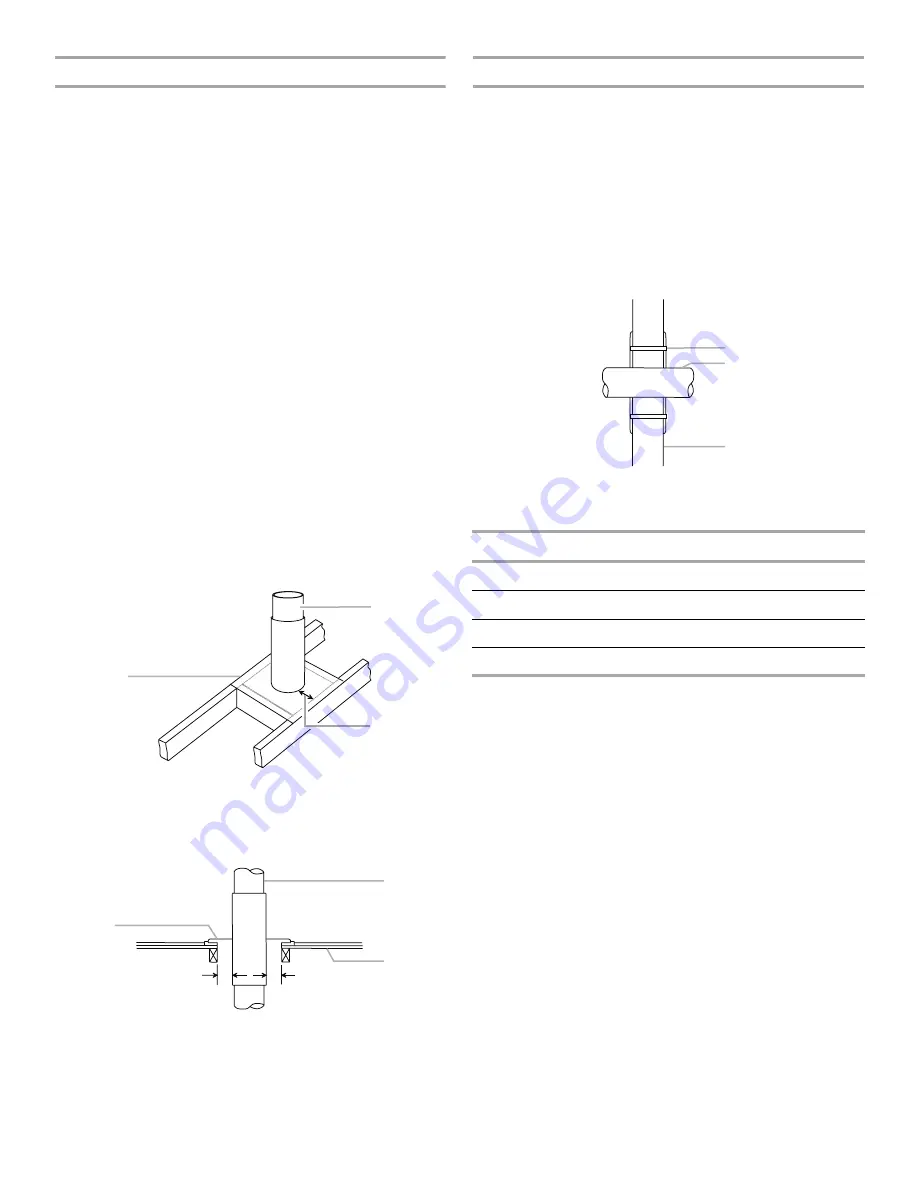

Vent Option—Vent Through Ceiling

Vent Option—Vent Through Floor

Sidewall Venting

This furnace can be sidewall (horizontally) vented with a listed

sidewall venter such as Field Controls Model SWG-4HD with CK-

43 Control Kit, or Tjernlund Model GPAK-JT. See the Sidewall

Venter Limitations Chart following.

Category I venting classification is maintained when vented in

this manner. The furnace, power venter and control kit (where

applicable) must be installed in accordance with their installation

instructions and all applicable codes.

For horizontal runs of vent pipe, supports are required at 5 ft

intervals.

Vent Through Wall

A. 26 gauge galvanized firestop on top of framed opening

B. Flue pipe

C. 1" clearance between flue pipe and frame

A. Pipe collar (firestop)

B. Flue pipe

C. Floor

A

B

C

1"

1"

A

B

C

A. Thimble

B. Flue pipe

C. Combustible wall

Sidewall Venter Limitations Chart

Vent pipe diameter

4"

Minimum vent pipe length

4 ft

Maximum vent pipe length

25 ft*

Maximum number of 90° elbows

4

*When fewer than 4 elbows are used, maximum vent pipe

length can be increased by 5 ft per unused elbow.

A

B

C

Summary of Contents for WGFBLT

Page 23: ...23 Wiring Schematic DRAIN LOW ...

Page 25: ...25 ...

Page 26: ...26 Notes ...

Page 27: ...27 Notes ...