19

Routine Maintenance

FIG. 36

Broom

Handle

Pencil

Mark

1” - 2”

Salt

Salt

Bridge

Water

Level

Push Tool into

Salt Bridge to

Break

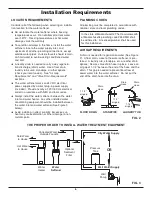

FIG. 37

Cap

O-ring Seal

Screen Support

Screen

Gasket

*Flow Plug (HVDC)

Housing

Ferrule

Nut

Cone Screen

*Flow Plug

*Install with lettered

side up, concave

side down.

CLEANING THE NOZZLE & VENTURI

A clean nozzle & venturi (See Figure 37) is a necessity

for the water softener to work properly. This small

component creates the suction to move brine from the

brine tank, into the resin tank. If it should become

plugged with sand, silt, dirt, etc., the water softener will

not work, and hard water will result.

Nozzle & Venturi Disc

IMPORTANT: Be sure small hole in the gasket is cen-

tered directly over the small hole in the nozzle & ven-

turi housing. Be sure the numbers are facing up

ADDING SALT

Lift the salt lid and check the salt storage level fre-

quently. If the water softener uses all the salt before

you refill it, you will experience hard water. Until you

have established a refilling routine, check the salt

every two or three weeks. Always add if less than 1/4

full. Be sure the brinewell cover is on.

NOTE:

If using potassium chloride (KCl), do not fill

above level 4 on the brinewell scale.

NOTE:

In humid areas, it is best to keep the salt stor-

age level lower, and to refill more often to

avoid salt “bridging”.

Recommended Salt: Nugget, pellet or coarse solar

salts with less than 1% impurities.

Salt Not Recommended: Rock salt, high in impurities,

block, granulated, table, ice melting, ice cream making

salts, etc.

BREAKING A SALT BRIDGE

Sometimes, a hard crust or salt “bridge” forms in the

brine tank. It is usually caused by high humidity or the

wrong kind of salt. When the salt “bridges,” an empty

space forms between the water and the salt. Then,

salt will not dissolve in the water to make brine.

Without brine, the resin bed is not recharged and hard

water will result.

If the storage tank is full of salt, it is difficult to tell if

you have a salt bridge. A bridge may be underneath

loose salt. Take a broom handle, or like tool, and hold

it next to the water softener. Measure the distance

from the floor to the rim of the water softener. Then,

gently push the broom handle straight down into the

salt. If a hard object is felt before the pencil mark is

even with the top, it is most likely a salt bridge. Gently

push into the bridge in several places to break it. Do

not use any sharp or pointed objects as you may

puncture the brine tank. Do not try to break the salt

bridge by pounding on the outside of the salt tank.

You may damage the tank.

To get access to the nozzle & venturi, remove the

water softener’s top cover. Put the bypass valve(s)

into the bypass position. Be sure the water softener is

in soft water (service) cycle (no water pressure at noz-

zle & venturi). Then, holding the nozzle & venturi

housing with one hand, un screw the cap. Do not lose

the o-ring seal. Lift out the screen support and screen.

Then, remove the nozzle & venturi disc, gasket and

flow plug(s). Wash the parts in warm, soapy water

and rinse in fresh water. Be sure to clean both the top

and bottom of the nozzle & venturi disc. If needed,

use a small brush to remove iron or dirt. Do not

scratch, misshape, etc., surfaces of the nozzle & ven-

turi.

Gently replace all parts in the correct order. Lubricate

the o-ring seal with silicone grease and locate in place.

Install and tighten the cap by hand, while supporting

the housing. Overtightening may break the cap or

housing. Put the bypass valve(s) into service (soft

water) position.

Recharge the softener to reduce water level in the

tank. This will also assure that the softener is com-

pletely recharged and ready to provide softened water

again. Check the water level in the tank by looking

down the brinewell. If the water level does not drop

after a recharge, the problem has not been resolved.

Call 1-866-986-3223, Monday - Friday, 8 am to 7 pm,

EST.