2

IMPORTANT: The United States Environmental Protection

Agency (EPA) has issued various regulations regarding the

introduction and disposal of refrigerants in this unit. Failure to

follow these regulations may harm the environment and can lead

to the imposition of substantial fines. These regulations may vary

by jurisdiction. A certified technician must perform the installation

and service of this product. Should questions arise, contact your

local EPA office.

This product is designed and manufactured to permit installation

in accordance with national codes. It is the installer’s

responsibility to install this unit in accordance with national codes

and/or prevailing local codes and regulations.

INSTALLATION REQUIREMENTS

These instructions are intended as a general guide only and do

not supersede any national or local codes in any way.

Compliance with all local, state, or national codes pertaining to

this type of equipment should be determined prior to installation.

Read this entire instruction manual, as well as the instructions

supplied in separate equipment, before starting the installation.

All models are designed for indoor installation only.

The installation of the air handler, field wiring, warm air ducts, etc.

must conform to the requirements of the National Electrical

Code, ANSI/NFPA No. 70 (latest edition) in the United States, and

any state laws, and local ordinances (including plumbing or

wastewater codes). Local authorities having jurisdiction should

be consulted before installation is made. Such applicable

regulations or requirements take precedence over the general

instructions in this manual.

Install the conditioned air plenum, ducts and air filters (not

provided) in accordance with NFPA 90B Standard for the

Installation of Warm Air Heating and Air-Conditioning Systems

(latest edition).

The air handler is provided with flanges for the connection of the

plenum and ducts.

Air filters (not provided) must be listed as Class 2 furnace air

filters.

The air handler may be used with an optional modular evaporator

coil (WMAH) in upflow, counterflow, or horizontal applications.

See “Installation Configuration Options” in “Installation

Configurations” for acceptable system configurations. The

mounting plates and the necessary hardware to connect the air

handler and modular evaporator coil cabinets together are

included with this air handler.

Goodman 33

WARNING

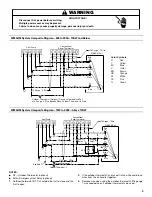

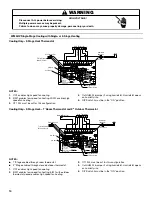

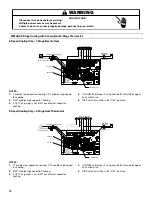

This product is factory-shipped for use with 208/240/1/60

electrical power supply. DO NOT reconfigure this air

handler to operate with any other power supply.

Goodman 34

WARNING

To avoid property damage, personal injury or death due to

electrical shock, this unit MUST have an uninterrupted,

unbroken electrical ground. The electrical ground circuit

may consist of an appropriately sized electrical wire

connecting the ground lug in the unit control box to the

building electrical service panel.

Other methods of grounding are permitted if performed

in accordance with the National Electric Code (NEC)

/American National Standards Institute (ANSI) /National

Fire Protection Association (NFPA) 70 and local/state

codes. In Canada, electrical grounding is to be in

accordance with the Canadian Electric Code (CSA) C22.1.

Goodman 35

When installing or servicing this equipment, safety

clothing, including hand and eye protection, is strongly

recommended. If installing in an area that has special

safety requirements (hard hats, etc.), observe these

requirements.

CAUTION

Goodman 37

WARNING

To prevent the risk of property damage, personal injury, or

death, do not store combustible materials or use gasoline

or other flammable liquids or vapors in the vicinity of this

unit.

Goodman 38

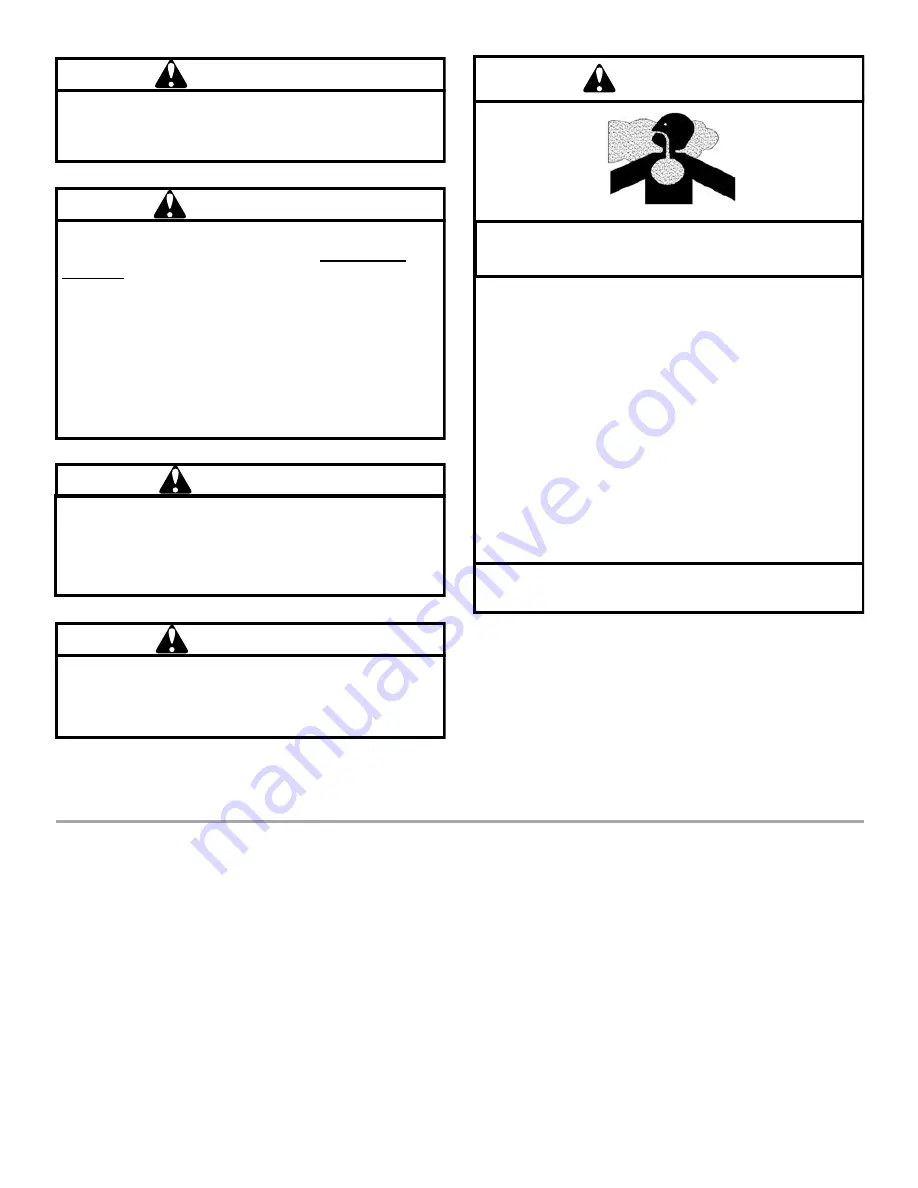

CARBON MONOXIDE POISONING HAZARD

Special Warning for Installation of Furnace or Air Handling

Units in Enclosed Areas such as Garages, Utility Rooms or

Parking Areas.

Carbon monoxide producing devices (such as an

automobile, space heater, gas water heater, etc.) should

not be operated in enclosed areas such as unventilated

garages, utility rooms or parking areas because of the

danger of carbon monoxide (CO) poisoning resulting from

the exhaust emissions. If a furnace or air handler is

installed in an enclosed area such as a garage, utility room

or parking area and a carbon monoxide producing device is

operated therein, there must be adequate, direct outside

ventilation.

This ventilation is necessary to avoid the danger of CO

poisoning which can occur if a carbon monoxide producing

device continues to operate in the enclosed area. Carbon

monoxide emissions can be (re)circulated throughout the

structure if the furnace or air handler is operating in any

mode.

CO can cause serious illness including permanent brain

damage or death.

DANGER