21

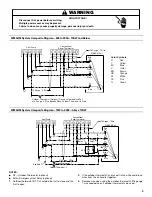

Motor Speed Adjustment

Each WMAHV blower motor has been preprogrammed for

operation at 4 distinct airflow levels when operating in cooling/

heat pump mode or electric heat mode. These 4 distinct levels

may also be adjusted slightly lower or higher if desired.

The adjustment between levels and the trim adjustments are

made by changing the DIP switch(s) either to an OFF or ON

position.

DIP Switch Functions

The WMAHV blower motor has an electronic control that contains

an 8-position DIP switch. The functions of these DIP switches are

shown in the following chart.

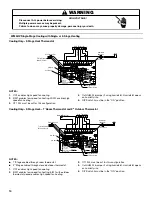

CFM Delivery

The following table shows the CFM output for DIP switch combinations 1 and 2, and for 5 and 6.

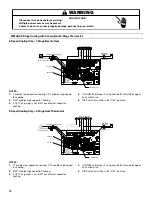

Thermostat—Fan Only Mode

During Fan Only Operations, the CFM output is 30% of the

cooling setting.

CFM Trim Adjustment

Minor adjustments can be made through the DIP switch

combination of 7 and 8. The following table shows the DIP switch

position for this feature.

NOTE: The airflow will not make the decreasing adjustment in

Electric Heat mode.

NOTE: If no adjustment is required, DIP switches 7 and 8 should

be left in the OFF position.

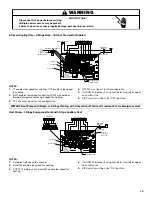

Humidity Control

When using a humidistat (normally closed), cut jumper PJ6 on the

control board. The humidistat will only affect the cooling airflow

by adjusting the airflow to 85%.

2-Stage Heating

When using staged electric heat, cut jumper PJ4 on the control

board.

DIP Switch Number

Function

1

Electric Heat

2

3

N/A

4

Indoor Thermostat

5

Cooling/Heat Pump CFM

6

7

CFM Trim Adjust

8

Model

Switch 1

Switch 2

Electric Heat CFM

Switch 5

Switch 6

Cooling/Heat Pump CFM

WMAHV 1200

Off

Off

1,200

Off

Off

1,200

On

Off

1,000

On

Off

1,000

Off

On

800

Off

On

800

On

On

600

On

On

600

WMAHV 1600

Off

Off

1,600

Off

Off

1,600

On

Off

1,400

On

Off

1,400

Off

On

1,200

Off

On

1,200

On

On

1,000

On

On

1,000

WMAHV 2000

Off

Off

1,900

Off

Off

2,000

On

Off

1,600

On

Off

1,800

Off

On

1,400

Off

On

1,600

On

On

1,200

On

On

1,200

CFM

Switch 7

Switch 8

+10%

On

Off

-15%

Off

On