MAINTENANCE

EN / M-SQ20 / 25 / November 2010

25

4.3 Regular

maintenance

CHECK DAILY:

•

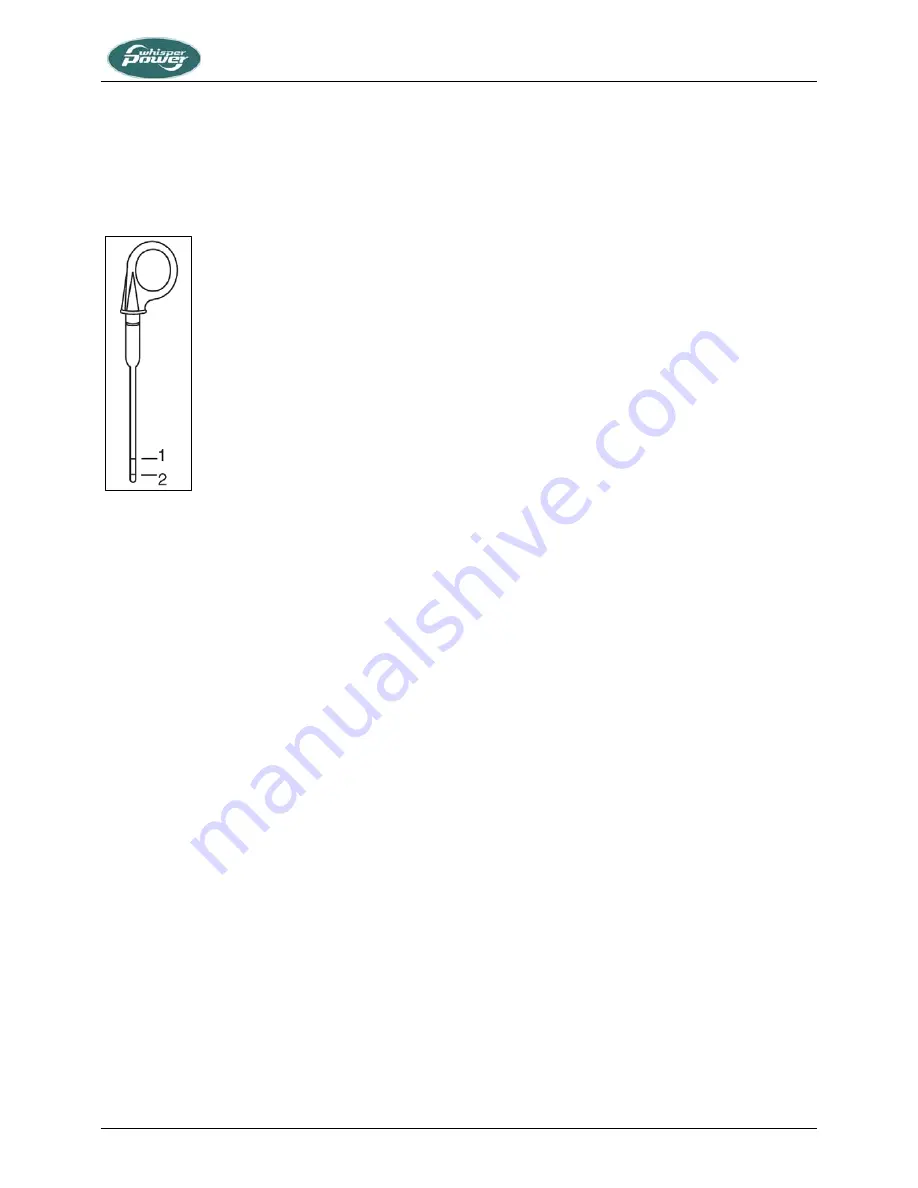

Oil level

Take care the oil level is never below the mark. Do not add

oil when the level is still above the mark.

1 Max. oil level;

2 Min. oil level.

Fig. 23. Engine oil dipstick markings

•

Level cooling liquid

•

Hoses for loose connections or deterioration.

•

Water inlet filter.

•

V-belt

tension

AFTER FIRST 50 HOURS:

•

Change oil and replace the oil filter.

Have the engine run until it is on temperature and

stop it. Replace the filter. Drain oil by the sump

pump into a suitable retainer and fill up with fresh

oil. Start the engine again and have it run for 5

minutes. Stop the engine again and pause for a

few minutes to let the oil gather in the crankcase.

Check the level again and add oil when

necessary.

•

Check and tighten nuts, bolts, and unions, paying

particular attention to the fuel system.

•

Observe the exhaust at the normal full load. The

exhaust must be free from soot. Do not allow the

engine to run with a dirty exhaust without

investigating the cause as this may result in an

expensive breakdown.

•

Check air vent (siphon breaker valve) on a

regular basis. When the air vent it not working

properly, the engine can fill up with water by

siphoning. Water in the combustion chamber

causes serious damage to the engine.

•

Check and readjust V-belt.

•

Check the electrical connections

EVERY 150 HOURS:

•

Change oil.

•

Check the battery acid level (not for

WhisperPower batteries).

•

Check battery terminals for corrosion

•

Check and readjust V-belt

•

Check impeller raw water pump (durability

depends on the purity of the sea water. In sandy

water and warm water wear will increase).

When replacing the impeller the gasket between the pump

case and the cover should be replaced as well. So when

ordering a spare impeller order a gasket as well. Remove

the cover to get access to the impeller. Remove the old

impeller with the help of two screwdrivers. Install the new

impeller and add some grease. Turn the blades in the

direction of rotation of the pump.

EVERY 300 HOURS:

•

Replace the impeller of the raw water pump.

•

Retighten the cylinder head bolts and adjust the

valve clearance. (See paragraph 5.4.2).

•

Check air cleaner element.

•

Replace the oil filter.

•

Replace the fuel filter

Replacement depends or the condition of the

fuel. We recommend replacement every 300

hours.

EVERY 1000 HOURS:

•

Replace the V-belt.

•

Retighten cylinder head bolts/ check and

adjust valve clearance.

EVERY 2000 HOURS:

•

Check lubricating oil pressure

•

Clean and check or replace fuel injector nozzles

and check injection pressure.

•

Check the air cleaner element:

The air is taken from the section between the

alternator and the engine

•

Check the cooling system:

The engine cooling liquid is indirectly cooled by

raw water via a heat exchanger. The seawater is

pumped by the PTO driven impeller pump. All

parts of the cooling system are of corrosion free

and seawater resistant materials such as naval

brass and copper/nickel. In case of gathering of

dirt in the system it could be cleaned by

compressed air. When overhauling the engine

one could clean the parts thoroughly or replace.

When the generator set runs less than 150 hours a year

the oil should be changed yearly