June 2021 W-SQ-Pro 15 and W-SQ-Pro 18

19

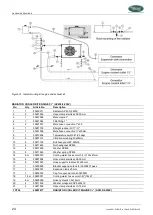

3 INSTALLATION SPECIFICATIONS

3.1

GENERAL

1

Make a hole for combustion air in the sound shield.

Mount an air inlet filter (if required).

2

Mount the generating set directly, without additional

vibration dampers, on a solid surface.

3

Mount the cooling system for the engine.

4

Connect exhaust system.

5

Connect ‘fuel supply line’ to the water separator/ fuel

filter.

6

Connect ‘fuel return line’ to the fuel tank.

7

Connect remote panel (just plug in).

8

Connect the AC cable from the AC box to the power

source selector.

9

Connect plus and minus from the 12V starter battery to

the battery cables.

10 Connect the power supply of the radiators.

11 Install a WhisperPower battery charger (optional).

3.2

COMMISSION TABLE

1

Check if a hole for combustion air intake is in the sound

shield. Also check if an air inlet filter for combustion air

is necessary and has been installed.

2

Check if the cooling system for the engine is properly

installed. Note that air traps must be avoided.

3

Check if the exhaust system is properly installed.

Check maximum length of exhaust hose, diameter of

exhaust piping.

4

Check all coolant connections.

5

Check the AC cables and the grounding.

6

Check if an AC breaker is installed before or after the

power source selector. When there is only a circuit

breaker, use it to disconnect the generating set from

the grid.

7

Check all DC connections, check if the battery switch/

circuit breaker is closed.

8

Open the fuel valve. Check if there are no air leaks in

the fuel supply line, and check if the lift of the fuel is

less than 1 meter. Check if there is no air in the water

fuel separator.

9

Check if the air intake in the canopy is not blocked.

10 Check the oil level and color of the oil. Check the

coolant level of both the alternator cooling and the

engine cooling.

11 To bleed the fuel system:

•

W-SQ- PRO 15 1phase / 3phase: push the “Start”

button on the local control (not on the remote

panel) and hold at least 5 seconds or as long as

necessary to bleed the system.

•

W-SQ- PRO 18 1phase / 3phase: use the manual

pump by turning the cap loose and pumping as

long as necessary to bleed the system. See

chapter 4.2.2 of the User Manual.

12 Start the engine by pushing the start button.

13 Check when the generating set is running, the delay of

5 to 10 seconds in the power source selector transfer.

14 Check voltage and frequency under ‘no load’

conditions.

15 Check voltage and frequency under ‘full load’

conditions.

16 Check if the battery charger of the generating set is

working (max. 14.5 Volt).

17 Close the sound shield and check the noise level.

18 Stop the generating set and check the engine again for

leakages of oil, fuel or coolant.