Page 10

Page 11

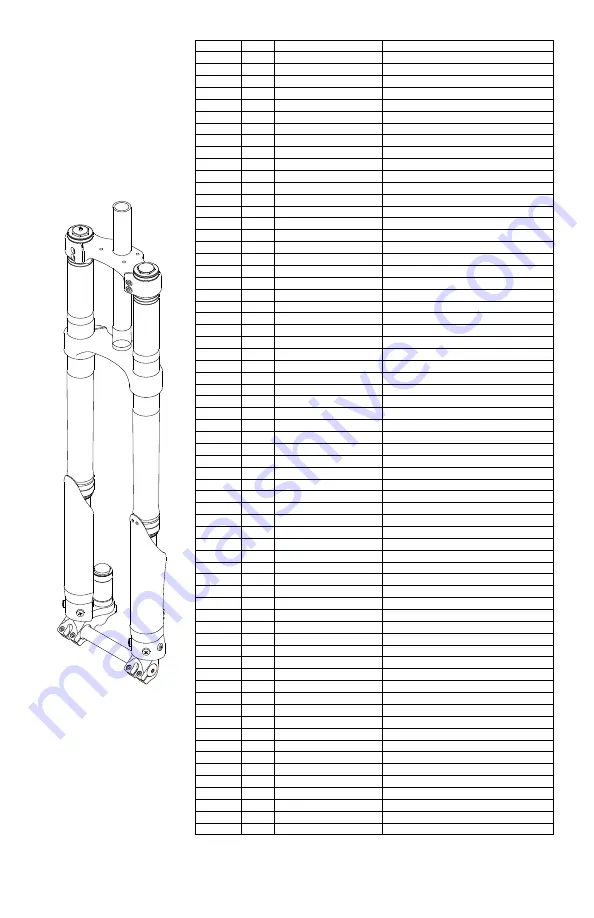

ITEM NO.

QTY. PART NO.

DESCRIPTION

1

2 100021-100022

DH Outer Leg

2

1 P1159-1

Crown Assm.

3

1 P1157-110

Upper Crown

4

1 100046

Main Spring

5

1 100609

Spring Leg Assm.

6

1 100610

Damper Leg Assm.

7

1 97-3677

Axle

8

2 97-1351

Wiper Seal

9

1 101468

Seal Head

10

1 100600

DH Air Cap

11

1 P2348

DH Damping Cap

12

1 97-3500

Bottom Out Spring

13

1 100612

Spring Seperator Seal

14

1 100613

Control Rod

15

1 100043

Negative Spring VT

16

1 100614

Control Rod End

17

1 97-3342

Bumper Soft

18

1 P3321

Rebound Bumper Spacer

19

2 100262

O-Ring 211

20

2 100054

Schreader Valve Assembly

21

1 P3220

Spring Progression

22

1 100615

Seal Head

23

1 100616

Top Cap Plug

24

1 P3290

Compression Bumper Medium

25

1 97-3914

Spring Spacer 5mm

26

1 P2028

DH Damper Shaft

27

1 P2035

Needle Assm.

28

1 97-1409

Shaft Seal

29

1 P2014

Check Valve Guide

30

1 P2015

Check Valve Spring

31

1 P2004

Check Valve 22x12x0.02

32

1 P2012

Piston

33

1 P3000

Piston Band

34

1 P2006

Low Spd Shim 22x8x0.02

35

1 P2005

Belvil Washer

36

1 P4010

Shim Stack Bolt

37

1 P3026

O-Ring 024

38

1 P1515-1

Reservoir Can

39

1 P2001B

Shim

40

1 29-136

Shim

41

1 P2016

Compression Piston

42

1 P3028

O-Ring 021

43

3 29-127

Shim

44

1 P4011

Piston Bolt

45

2 P3021

O-Ring 118

46

1 P2010

Floating Piston Assm.

47

1 100162

O-Ring 2x22.5

48

1 100627

Air Cap Triple Clamp Series

49

2 P4650

Dust Cap

50

1 98-406-1

LH Stone Guard

51

1 98-406-2

RH Stone Guard

52

6 P4005

Screw Nylon Guard

53

4 97-9200

M5x16mm Screw

54

11 97-852

Bolt M6

55

1 97-9300

Star Nut

56

2 P4301

C Clip

57

2 P3060

Oil Seal

58

8 97-986

DU Bushing

59

1 100617

Spacer

60

1 100618

Topout Stop

61

2 100033

O-Ring 010

62

1 P4015

Retaining Pin

63

1 P4004

Compression Adjuster Screw

64

2 97-1418

O-Ring 006

65

2 P4051

Set Screw 6mm x 6

66

1 100531

Axle End Bolt

MAINTENANCE LOG

Date

Service Performed