Page 52

23835-1-0607

Please Note

It is normal for appliances fabricated of steel to give off

some expansion and/or contraction noise during the start

up or cool down cycle. Similar noises are found with your

furnace heat exchanger or car engine.

It is not unusual for your gas fireplace to give off some odor the

first time it is burned. This is due to the curing of the paint and any

undetected oil from the manufacturing process.

Please ensure that your room is well ventilated - open all

windows.

It is recommended that you burn your fireplace for at least

six (6) hours the first time you use it. Place fan in the “OFF”

position during this time.

IMPORTANT:

Turn off gas before servicing appliance. It is

recommended that a qualified service person perform these check-

ups at the beginning of each heating season.

• Clean Burner and Control Compartment

Keep the control compartment, logs, and burner areas surrounding

the logs clean by vacuuming or brushing at least twice a year.

Cleaning Procedure

1. Turn off pilot light at gas valve.

2. Remove glass front. (See Glass Removal)

3. Vacuum burner compartment.

4. Reinstall glass front.

5. Ignite pilot. (See Lighting Instructions)

6. Operate the pilot burner. If it appears abnormal call a service

person.

• Check Vent System

The appliance and venting system should be inspected before

initial use and at least annually by a qualified service person.

Inspect the external vent cap on a regular basis to make sure

that no debris is interfering with the air flow.

Glass Cleaning

It will be necessary to clean the glass periodically. During start-up

condensation, which is normal, forms on the inside of the glass and

causes lint, dust and other airborne particles to cling to the glass

surface. Also initial paint curing may deposit a slight film on the

glass. It is therefore recommended that the glass be cleaned two or

three times with a non-abrasive household cleaner and warm water

(we recommend gas fireplace glass cleaner). After that the glass

should be cleaned two or three times during each heating season

depending on the circumstances present.

General Glass Information

Warning: Do not operate appliance with the glass front

removed, cracked or broken. Replacement of the glass should

be done by a licensed or qualified service person.

Only glass approved for use by the manufacturer in fireplace may

be used for replacement. The glass replacement should be done by

a licensed or qualified service person.

WARNING:

1. The use of substitute glass will void all product warranties.

2. Care must be taken to avoid breakage of the glass.

3. Under no circumstances should this appliance be operated without

the glass front or with a broken glass front. Replacement of the

glass (with gasket) as supplied by the manufacturer should be

done by a qualified service person.

4. Do not abuse the glass by striking or hitting the glass.

WARNING: Do not use abrasive cleaners on glass. Do not

attempt to clean glass when glass is hot.

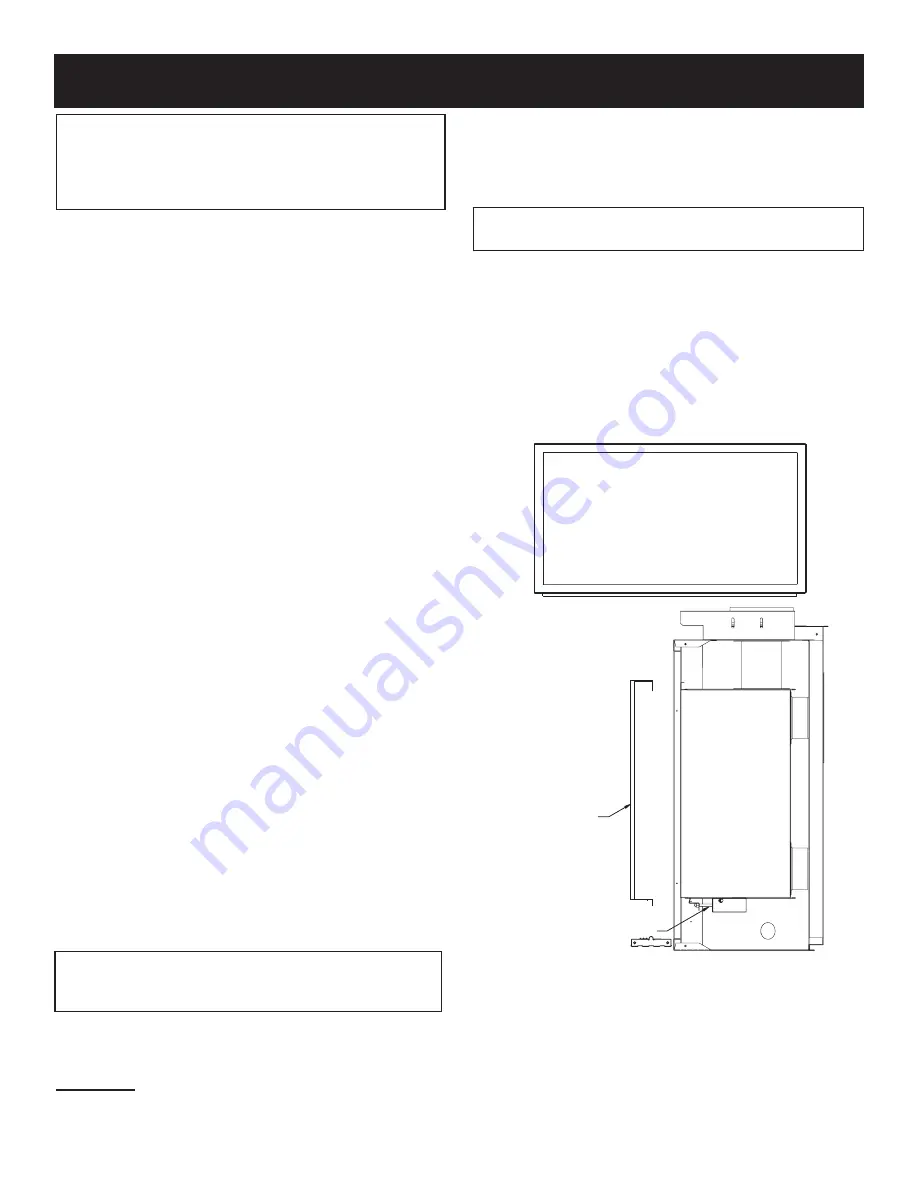

Glass Removal and Replacement (Figure 68)

1. Remove top louver, grasp louver and pull forward.

2. Lower bottom louver.

3. Release two glass frame clamps at bottom of firebox.

4. Remove glass frame.

5. Place glass frame onto firebox.

6. Attach two glass frame clamps at bottom of firebox.

7. Align clips on top louver with slots on front posts. Replace top

louver into fireplace.

8. Close bottom louver.

Louver Removal and Installation

1. Remove top louver, grasp louver and pull forward.

2. Lower bottom louver.

3. Align clips on top louver with slots on front posts. Replace top

louver into fireplace.

4. Close bottom louver.

GLASS FRAME

ASSEMBLY

GLASS FRAME CLAMP

Figure 68

MAINTENANCE AND SERVICE