25233-0-0109

Page 9

oPtionaL SingLE SPEED BLoWER inStaLLation inStRUctionS

Attention:

install blower assembly before connecting gas inlet

supply line.

wiring

the appliance, when installed, must be electrically grounded in

accordance with local codes or, in the absence of local codes,

with the

National Electrical Code, ANSI/NFPA 70

, if an exter-

nal electrical source is utilized.

This appliance is equipped with

a three-prong [grounding] plug for your protection against

shock hazard and should be plugged directly into a properly

grounded three-prong receptacle. Do not cut or remove the

grounding prong from this plug.

For an ungrounded receptacle,

an adapter, which has two prongs and a wire for grounding, can

be purchased, plugged into the ungrounded receptacle and its wire

connected to the receptacle mounting screw. With this wire com-

pleting the ground, the appliance cord plug can be plugged into

the adapter and be electrically grounded.

caution:

Label all wires prior to disconnection when servic-

ing controls. Wiring errors can cause improper and dangerous

operation. Verify proper operation after servicing.

Note:

Junction box on right side of firebox must be pre-wired at

time of firebox installation for use with blower assembly. A

standard wall on/oFF wall switch or optional ScV1 Vari-

able Speed control Kit should be installed to activate pow-

er to the Firebox, and control the operation of the FBB5

Blower assembly. it is recommended that installation of the

wiring be performed by a qualified electrician.

See Figure

12.

1. If installed, turn OFF gas supply to firebox/gas log.

2. If applicable, turn OFF electric supply to firebox.

cAuTION:

aLL WiRing SHoULD BE DonE BY

a QUaLiFiED ELEctRician anD SHaLL BE in

coMPLiancE WitH aLL LocaL, citY anD StatE

BUiLDing coDES. BEFoRE MaKing tHE ELEctRi-

caL connEction, MaKE SURE tHat Main PoWER

SUPPLY iS DiSconnEctED. tHE aPPLiancE, WHEn

inStaLLED, MUSt BE ELEctRicaLLY gRoUnDED

in accoRDancE WitH LocaL coDES, WitH tHE

nationaL ELEctRicaL coDE anSi/nFPa 70 (Lat-

ESt EDition).

a factory installed junction box is located on the lower right

side of the firebox. Wiring must be fed to the junction box and

attached to the receptacle that is provided. From right side of

the firebox, remove the screw securing the junction box as

-

sembly. Leave approximately 6” of wire in the junction box

for connection.

attach black wire to one side of the receptacle and white wire

to opposite side of receptacle. the ground wire should be at-

tached to the green (ground) screw.

install the receptacle into the junction box. attach cover

plate.

Attention:

if installed, do not damage gas inlet supply line

when blower assembly is inserted into firebox. In some cases,

removal the gas inlet supply line may be necessary.

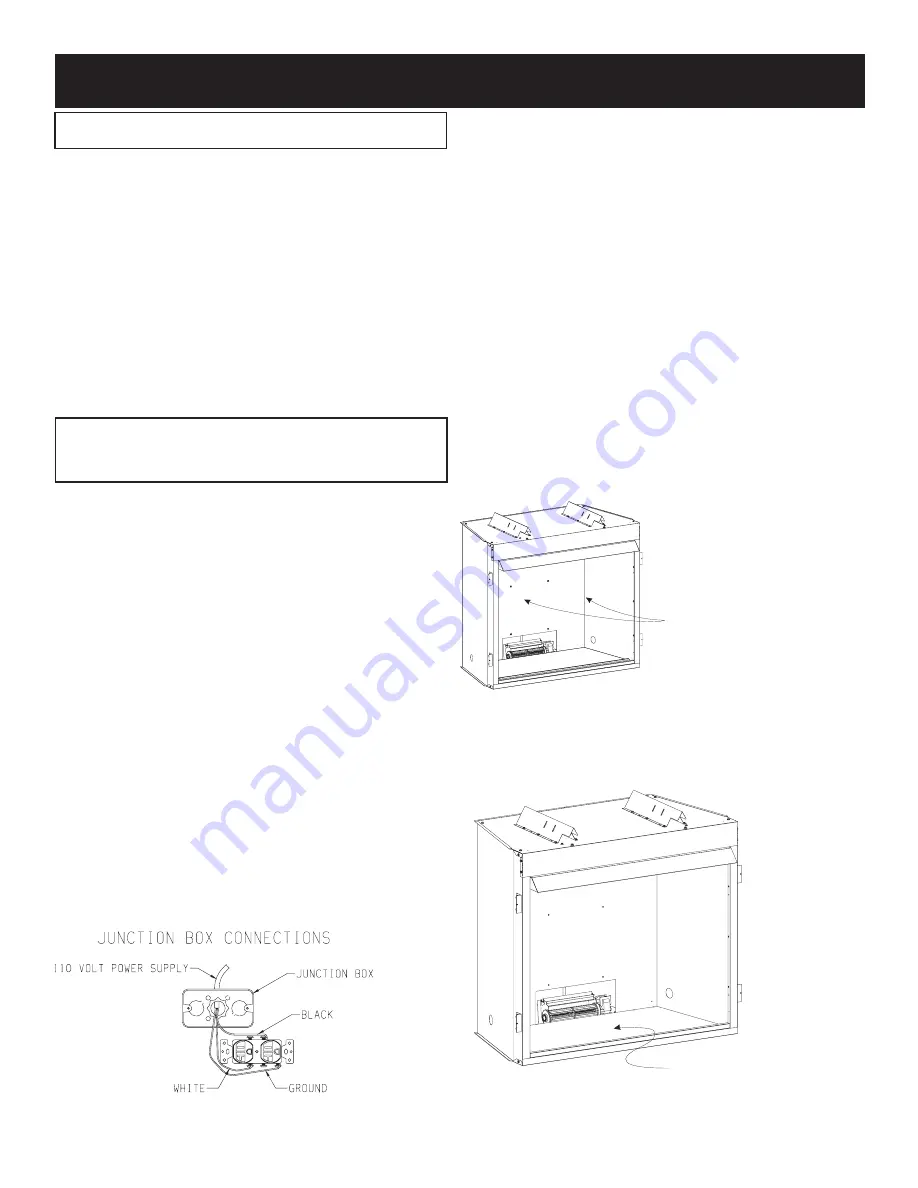

Figure 12

REMOVE SIDE BRICK AND BACK BRICK

PANELS TO GAIN ACCESS FOR BLOWER

INSTALLATION.

NOTE: IF THE BLOWER CAN BE INSTALLED

PRIOR TO FIREBOX INSTALLATION, IT MAY

BE EASIER TO REMOVE THE REAR COVER

PLATE PANEL ON THE BACK OF THE FIREBOX

RATHER THAN REMOVING BRICK PANELS.

Select Firebox Models

Figure 13

NOTE: BRICK LINERS REMOVED

TO SHOW INSTALLATION

OF BLOWER ACCESSORY.

Figure 14