Page 25

19400-3-0406

With proper installation and maintenance, your new Gas Fireplace will provide years of trouble-free service. If you do experience a

problem, refer to the troubleshooting guide below. This guide will assist a qualified service person in the diagnosis of problems and

the corrective action to be taken. Refer to page 24 for initial startup and GAS Line purge instructions.

SYMPTOM

CHECK

ACTION

No spark when system is turned to “ON”

and reset cycle* has been completed.

Check for 120V between black “hot” line

at control module and “white” return at

module.

If 120V not present, check fuse or circuit

breaker or repair wiring leading to

fireplace.

Spark for six (6) seconds at ignitor, but no

ignition of burner.

a. Check that gas is turned on and system

purged.

Turn gas on and/or purge system.

b. Check that tips of ignitor are directly

above ports on main burner. Spark is

between electrodes and not from one

electrode to burner.

Position electrodes so tips are directly

above burner port ports and about ¼" to

3

/

8

" above burner.

c. Check for 120V at each coil on the gas

valve and listen for click, indicating gas

valve is opening.

If 120V present, but gas valve does not

click, replace gas valve.

Spark for six (6) seconds, main burner

lights, but goes out when spark stops.

Check for clean ground path between

electrode bracket and fireplace chassis.

Check wiring to wiring diagram label.

Check for broken electrode on high-tension

lead attachment to module.

Clean, position according to wiring diagram,

and repair defective electric connections. If

all electrical connections are clean and

correct, replace module.

Main burner lights normally and then goes

out.

a. Check ignitor to burner gap.

Igniter should be located 1/4" to 3/8" above

burner area.

b. Check high-tension lead and connector

for shorts.

Replace spark electrode assembly.

c. Refer to installation instructions

troubleshooting guide for issues such

as venting.

Repair as required.

The conversion shall be carried out in accordance with the

requirements of the provincial authorities having jurisdiction

and in accordance with the requirements of the CSA B149.2

installation code (Canada) and with the requirements of the

National Fuel Gas Code Z223.1/NFPA 54 (United States).

WARNING: This conversion kit shall be installed by a

qualified service agency in accordance with the manufacturer's

instructions and all applicable codes and requirements

of the authority having jurisdiction. If the information in

this instruction is not followed exactly, a fire, explosion, or

production of carbon monoxide may result causing property

damage, personal injury, or loss of life. The qualified service

agency is responsible for the proper installation of this kit.

The installation is not proper and complete until the operation

of the converted appliance is checked as specified in the

manufacturer's instructions supplied with the kit.

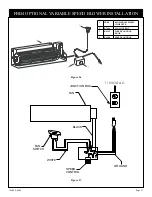

Installer notice:

Using an ink pen, fill out the required information

on the conversion label. Remove the backing from label and stick

label in a visible position on bottom of fireplace close to gas

valve.

Installer notice:

These instructions must be left with the

appliance.

Instructions for converting your direct ignition fireplace from

natural gas to propane/LP gas.

All direct ignition fireplaces are shipped from the factory equipped

to operate on natural gas. To convert the direct ignition fireplace

to operate on propane/LP gas, follow the instructions on Page

26. Please see the appropriate parts list for your model for parts

included with the direct ignition fireplace.

Check the items in the kit with the parts list. Notify the supplier of

any items that are missing before installing the conversion kit.

DIRECT IGNITION TROUBLESHOOTING

DIRECT IGNITION PROPANE/LP GAS CONVERSION