700 SERIES LAWN TRACTORS

44

17.46.Individually, these readings should lead a techni-

cian to inspect the connection between the sole-

noid and the ground path (e.g. mounting

hardware, green wire with eyelet beneath head

of solenoid mounting bolt), or the engine and the

frame (e.g. loose or rusty engine mounting

bolts).

17.47.If both of these readings were found on the

same tractor, a common point in the system

would be the primary suspect (e.g. poor connec-

tion between negative battery cable and frame).

17.48.Applying this principle to the positive side of the

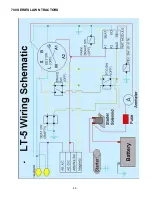

system: See Figure 17.48.

•

Ultimately, any positive current should find its

way from the positive post of the battery to its

destination through the wiring harness.

•

To check hot-side voltage drop: set-up a multim-

eter to measure 12V DC.

•

Make a good electrical connection between the

red ( + ) probe and the positive post on the bat-

tery.

•

Make a good electrical connection between the

black ( - ) probe and the suspect point of the cir-

cuit.

•

Power-up the circuit in question.

•

The voltage that shows-up on the meter is the

power that is not following the intended path

back to the negative battery post.

•

Voltage drop on a good circuit should be less

than 0.1 volts. A voltage drop reading on the

meter of greater than 0.2 volts indicates a fairly

substantial problem that demands attention.

17.49.As an example, if the tractor had a slow-turning

starter, the ground-side voltage drop measured

below 0.1 volts, and there was not a parasitic

load on the engine (e.g. PTO clutch that is not

fully disengaged), it would be logical for the tech-

nician to check voltage drop to the starter.

See Figure 17.49.

17.50.With the starter motor engaged, the voltage drop

reading here is nearly 0.6 volts, indicating a seri-

ous problem in the heavy-gauge circuit between

the starter and the battery.

17.51.Checking voltage-drop at various points along

the circuit can help pin-point the problem.

•

Check voltage-drop at the output lug on the

starter solenoid:

If there is a significant difference, the problem

lies between the lug on the solenoid and the lug

on the starter.

If there is little change, the problem lies further

up-stream.

•

Check voltage drop at the input lug on the sole-

noid:

If there is significant difference between the

reading there and the reading at the output lug

(greater than 0.10 volt), then the contacts inside

the solenoid may be burned.

If there is little change, the problem lies further

up-stream, between the battery and the sole-

noid.

•

Results may be cross-checked by testing volt-

age drop across the two posts of the starter sole-

noid while cranking the starter motor.

Figure 17.48

Figure 17.49

Summary of Contents for 700 Series

Page 2: ......

Page 4: ......

Page 50: ...700 SERIES LAWN TRACTORS 46 ...

Page 52: ...700 SERIES LAWN TRACTORS 48 ...