Page

181-887-14

9

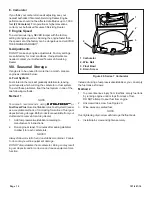

B. Removing Debris from Engine

Before each use, remove grass clippings, dirt and debris

from the following areas:

• Cooling fins

• Air intake screen

• Levers

• Linkage

• Air Inlet

NOTES

See “III. Filter Removal/Installation” instructions before re-

moving Air Cleaner Cover. Special care should be taken to

prevent damage when removing air cleaner cover. See Figure

16.

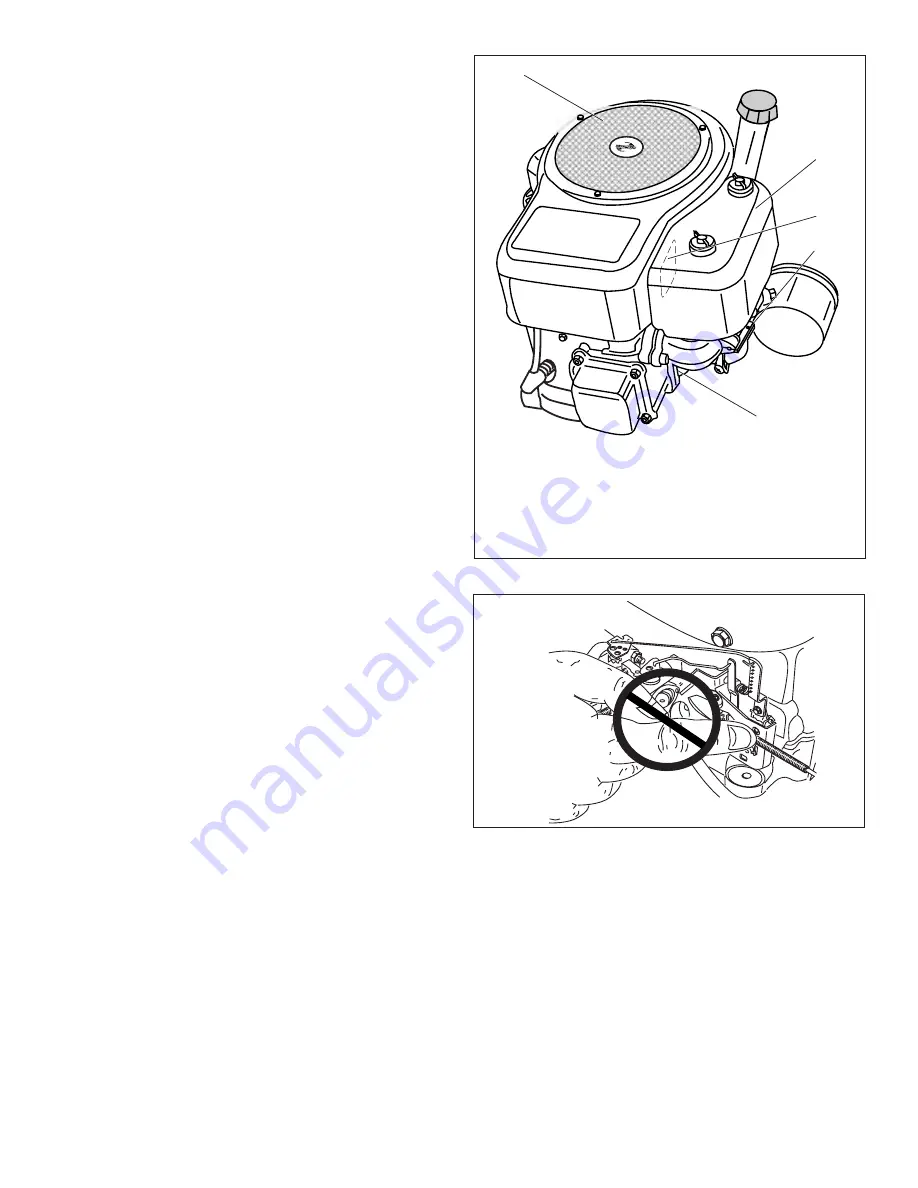

DO NOT bend levers and linkage with fingers. See Figure 17.

1.

See “III. Filter Removal/Installation” instructions.

2.

Remove Air Cleaner Cover and filters. See Figure 16.

3.

Remove debris from air inlet, air cleaner cover and air

intake screen.

4.

Inspect filter(s) for discoloration or dirt accumulation. If

either is present, see “Servicing Filters” instructions.

5.

Replace Air Cleaner Cover and Filters.

Removing debris will insure adequate cooling, correct engine

speed and reduce the risk of fire.

Figure 17. Linkage and Lever Bending

1. Cooling Fins

2. Levers and Linkage

3. Air Inlet

4. Air Cleaner Cover

5. Air Intake Screen

5

3

2

1

4

Figure 16. Debris Locations