6

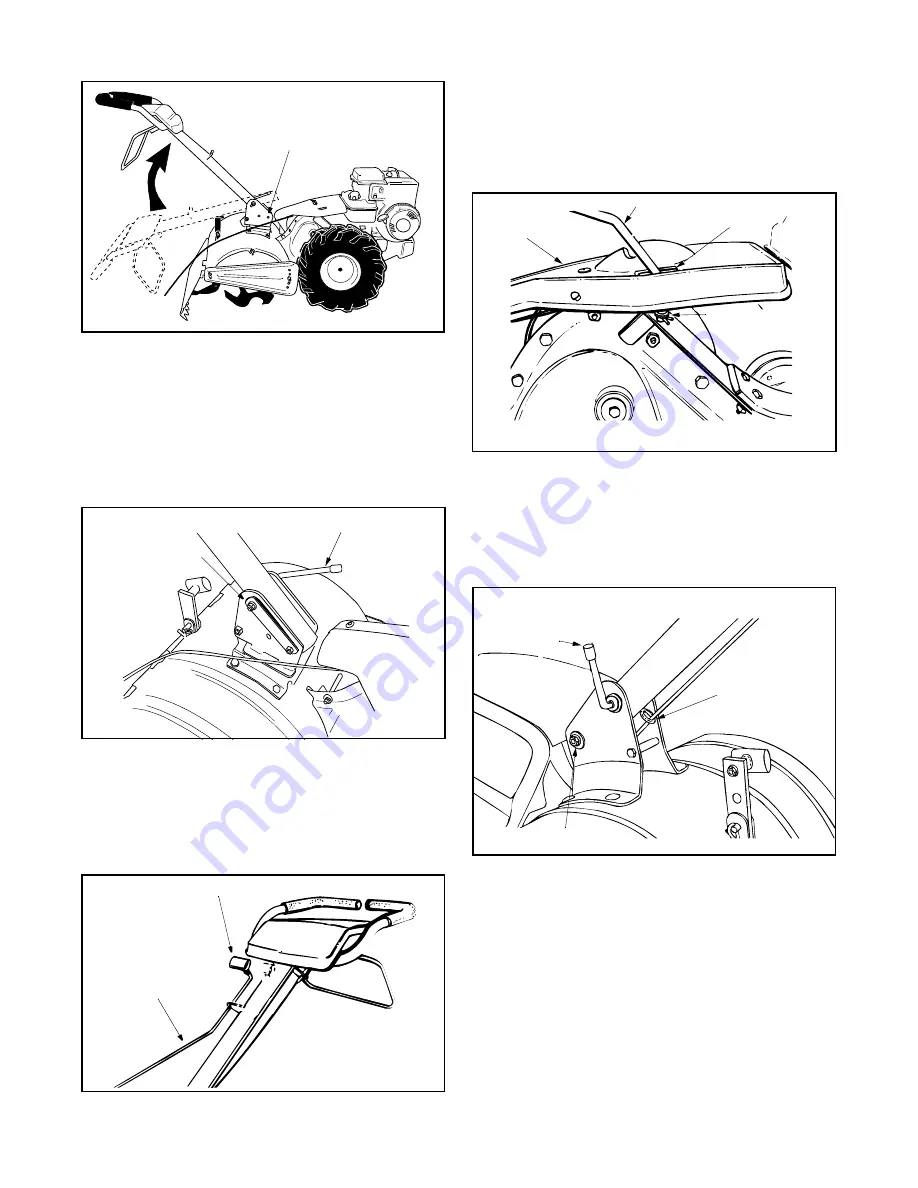

Figure 3

•

Place the hex opening of the hex nut retainer

bracket over the flange nut securing the handle

adjustment lock and install the lock nut on the lower

shoulder bolt. See Figure 4.

•

Pivot handle assembly into the highest position

possible. Tighten the bottom bolt and nut securely.

Tighten the handle adjustment lock.

Figure 4

Attaching The Gear Shift Rod

•

Remove the T-handle, nut, hairpin clip, flat washer

and rubber washer from the end of the gear shift

rod. Slide the rod up through the bracket on the

front of the handle assembly. See Figure 5.

Figure 5

•

Insert the end of the gear shift rod through the

opening in the top of the shift cover, and into the

shift bracket. Secure with rubber washer first, then

flat washer and hairpin clip. See Figure 6.

•

Install the nut and T-handle on the gear shift rod.

Figure 6

Attaching The Clutch Cable

•

Route the clutch cable underneath the handle and

through the cable clip. Be careful not to bend or

kink the cable. See Figure 7.

Figure 7

•

Remove one hex nut from the threaded casing on

the end of the cable and slip the wire up through the

slot on the cable bracket underneath the handle.

See Figure 8.

•

Push the end of the casing up through the cable

bracket. Rethread the hex nut on the end of the

cable. Do not tighten at this time.

•

Pull the cable upwards to obtain slack and from

right to left hook the “Z” end of the cable into the

bracket on the clutch control (beneath the handle

panel). Tighten the nut against the cable bracket.

See Figure 8.

Lift up

Handle

Flange Nut Retainer Bracket

Shoulder Bolt

Lock Nut

Hex Hole in

Retainer Bracket

over Flange Nut

Handle Adjustment

Lock

T-Handle

Gear Shift

Rod

Shift Cover

Gear Shift Rod

Opening

Rubber Washer

Flat Washer

Hairpin Clip

Handle

Adjustment

Lock

Cable

Clip

Flange Lock Nut