25

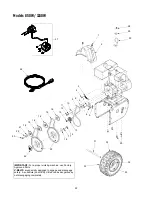

Models 850W / 1150W

Ref.

No.

Part No.

Part Description

1.

618-0043

Dogg Assembly: RH

2.

618-0044

Dogg Assembly: LH

3.

618-0303B

Shift Assembly: Steerable Drive

4.

656-0012A

Friction Wheel Disc Assy.

5.

684-0014B

Shift Rod Assembly

6.

684-0042B

Bearing

7.

784-5731A

Transmission Frame Assembly

8.

684-0131A

Support Bracket Assembly

9.

710-0599

Hex Washer Screw 1/4-20 x .5

10.

710-0809

Hex Washer Screw 1/4-20 x 1

11.

710-1652

Hex Screw 1/4-20 x .625”

12.

711-1267

Drive Shaft

13.

711-1268

Actuator Shaft

14.

711-1364

Pin

15.

712-0711

Jam Nut 3/8-24 Gr.8

16.

712-3017

Hex Nut: 3/8-16

17.

713-0233

Chain

18.

713-0374

Chain

19.

713-0413

Sprocket: 10T

20.

713-0472

Sprocket

21.

714-0104

Cotter Pin

22.

736-0142

Flat Washer

23.

714-0474

Cotter Pin

24.

716-0102

Snap Ring

25.

721-0263

Adhesive: Loctite

26.

732-0209

Extension Spring

27.

732-0264

Extension Spring

28.

736-0105

Bell Washer

29.

736-0160

Flat Washer

30.

736-0169

Lock Washer

31.

784-5740

Drive Cover LH

32.

736-0351

Flat Washer

33.

736-0626

Flat Washer

34.

737-0170

Lubricant: 6 in 1

35.

737-0318

Grease

36.

738-0924

Shoulder Screw

37.

741-1111

Hex Flange Bearing

38.

741-0598

Hex Flange Bearing

39.

741-0600

Ball Bearing

40.

741-0701

Flange Bushing

41.

746-0897

Auger Clutch Cable

42.

746-0898

Drive Clutch Cable

43.

746-0956

Steering Cable

44.

748-0190

Spacer

45.

750-1161A

Axle Support Tube

46.

750-1162

Spacer

47.

756-0625

Roller Cable

48.

784-5590

Shift Bracket

49.

784-5687A

Auger Cable Guide Bracket

50.

784-5689A

Front Support Guide Bracket

51.

784-5730A

Drive Cover RH

52.

784-5732

Frame Cover

53.

784-5733

Roller Bracket: Drive Cable

54.

710-1233

Oval C-Sunk Machine Screw

55.

712-0127

Weld Nut

56.

725-0157

Cable Tie

57.

746-0950

Turn Trigger

58.

714-0104

Cotter Pin

Ref.

No.

Part No.

Part Description

NOTE: For painted parts, please refer to the list of

color codes below. Please add the applicable color

code, wherever needed, to the part number to order

a replacement part. For instance, if a part, numbered

700-xxxx, is painted Oyster Gray, the part number to

order would be 700-xxxx-0662.

Oyster Gray: 0662

Powder Black: 0637

Red Metallic: 0650