6

Final Adjustments

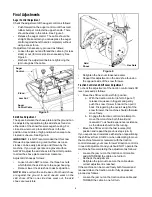

Auger Control Adjustment

Check the adjustment of the auger control as follows:

•

Push forward on the auger control until the small

rubber bumper contacts the upper handle. There

should be slack in the cable. See Figure 5 .

•

Release the auger control. The cable should be

straight. Make certain you can depress the auger

control against the left handle completely without

using excess force.

If adjustment is necessary, proceed as follows:

•

Loosen the jam nut and thread the cable in (for less

slack) or out (for more slack) as necessary. See

Figure 5 .

•

Recheck the adjustment before retightening the

jam nut against the cable.

Figure 5

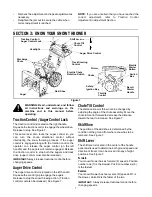

Skid Shoe Adjustment

The space between the shave plate and the ground can

be adjusted by repositioning the skid shoes found on

either side of the snow throwers auger housing. For

close snow removal, place skid shoes in the low

position. Use middle or high position when area to be

cleared is uneven. See Figure 6.

IMPORTANT:

It is NOT recommended that this snow

thrower be operated on a gravel surface, as loose

stones can be easily picked up and thrown by the

machine. If you must operate on a gravel surface,

ALWAYS adjust the skid shoes into the HIGH position

to allow the shave plate maximum clearance.

Adjust skid shoes as follows:

•

Loosen, but do NOT remove, the three hex nuts

which fasten the skid shoe to the auger housing.

•

Raise or lower the skid shoe to desired position.

NOTE: Make certain the entire base of both skid shoes

are against the ground to avoid uneven wear on the

skid shoes. When one side does wear out, the skid

shoes are reversible.

Figure 6

•

Retighten the hex nuts loosened earlier.

•

Repeat this adjustment on the skid shoe found on

the opposite side of the snow thrower.

Traction Control and Shift Lever Adjustment

To check the adjustment of the traction control and shift

lever, proceed as follows:

•

Move the shift lever into sixth (6) position.

a. With the traction control (refer to Figure 7)

released, squeeze in triggers and gently

push the snow thrower forward, then pull it

back. Disregarding the overall weight of the

snow thrower, the machine should otherwise

move freely.

b. Engage the traction control and attempt to

move them machine both forward and

rearward. You should experience resistance

as the wheels should not be turning.

•

Move the shift lever into the fast reverse (R2)

position and repeat the previous steps (a & b).

If you experienced resistance either when repositioning

the shift lever from 6 to R2 or when attempting to move

the machine forward or rearward with the traction

control released, your snow thrower’s traction control is

in need of adjustment and you should NOT operate the

machine before completing the adjustment as follows:

•

Loosen the jam nut on the traction control cable

and UNTHREAD the cable one full turn.

•

Recheck the adjustment.

•

Retighten the jam nut to secure the cable when

correct adjustment is reached.

If the machine can be moved freely both forward and

rearward when the traction control fully depressed,

proceed as follows:

•

Loosen the jam nut on the traction drive cable and

THREAD the cable in one full turn.

Auger

Control

Z-End

Jam Nut

Auger

Control Cable

Skid

Hex Nuts

Shoes