6

SECTION 5: ASSEMBLY INSTRUCTIONS

IMPORTANT:

This unit is shipped WITHOUT

GASOLINE or OIL. After assembly, see separate

engine manual for proper fuel and engine oil

recommendations.

NOTE:

Left and right is determined from the

operator’s position, standing behind the tiller.

TOOLS REQUIRED FOR ASSEMBLY

Adjustable Wrenches

Pair of Pliers

TO REMOVE UNIT FROM CARTON

1.

Remove staples, break glue on top flaps, or cut

tape at carton end and peel along top flap to

open carton.

2.

Remove loose parts included with unit (i.e.,

operator’s manual, etc.).

3.

Cut along dotted lines and lay carton down flat.

4.

Remove packing material.

5.

Roll or slide unit out of carton. Check carton

thoroughly for loose parts.

6.

Extend control cable and lay on the floor. Be

careful not to bend or kink control cable.

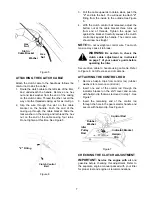

Figure 3

ATTACHING DEPTH STAKE ASSEMBLY

1.

Tip the tiller forward so it rests on front

counterweight.

2.

Raise the tine shield hinge flap assembly.

Remove "T" knob, flat washer and hex bolt from

depth stake. Insert the depth stake assembly in

front of spacer (under the tine shield) and up

through the tine shield assembly as shown in

Figure 3.

3.

Insert clevis pin through the tine shield and the

second hole from top of the depth stake. Secure

with hairpin clip.

4.

Insert hex bolt into the top hole of the depth

stake assembly. Place flat washer on hex bolt

and thread “T” knob onto the hex bolt. See

Figure 3. Tighten securely.

5.

Tip the tiller back down so it rests on the depth

stake (transport position).

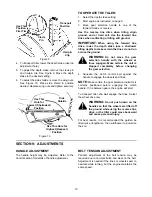

ATTACHING THE HANDLE ASSEMBLY

Figure 4

1.

Remove top two bolts and flange lock nuts from

handle mounting brackets as shown in Figure 4.

Do not remove the bottom bolt and nut.

2.

Place handle assembly in position between the

handle mounting brackets. See Figure 4.

3.

Line up holes in handle with holes in handle

mounting brackets. Secure with hardware

removed in step 1.

T-Handle

Hex Bolt

Washer

Depth

Stake

Stake

T-Knob

Hex Bolt

Washer

Clevis Pin

Hairpin Clip

Depth Stake

Remove

Handle

Ass’y

Handle

Bracket

Summary of Contents for 21A-458B190

Page 14: ...14 Model 458 ...