Cleaning and Disinfecting the Whirlpool

After draining the Whirlpool:

1. Verify that the turbine is OFF.

2. Remove any loose objects or debris that may be

present in whirlpool.

3. To Disinfect:

*Whitehall recommends that you disinfect the

whirlpool after each patient.

*Spray or wipe all surfaces of the whirlpool tank and

thermometer with a hard surface disinfectant,

following the disinfectant manufacturer's instructions.

*Rinse away disinfectant residue with warm, clean

water. If needed (or after the last patient of the day)

wipe the inside and outside surfaces of the whirlpool

with a towel to reduce streaking and spotting.

4. To Clean:

*Clean as needed, or weekly at minimum.

*Hand-wash all surfaces of the whirlpool and

thermometer with a non-abrasive stainless steel

cleaner. Scrub only in the direction of the polish lines

on the whirlpool. Follow the manufacture's

instructions for use.

*Rinse with cold water.

*Wipe inside and outside surfaces with a towel to

reduce streaks and spotting.

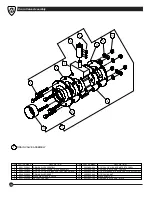

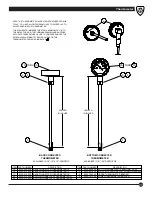

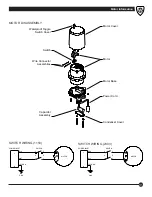

Disinfecting and Cleaning of the Turbine

1. Drain the tank.

2. Place an empty bucket beneath the turbine. Fill with

water and add disinfectant solution per manufacturers

recommended use.

3. Turn the control valve to the slow position.

4. Turn on the turbine for 5 seconds and turn it off. Allow

the turbine to soak for a 10 minute contact time.

5. Spray or wipe all exposed surfaces with a mixture of

suitable disinfectant solution per manufacture’s

recommended use. Exposed surfaces should remain

wet for at least 10 minutes.

6. Drain the turbine bucket into the tank and open drain.

7. Rinse all exposed surfaces with warm/hot water.

8. Fill the bucket with water and run turbine for five

seconds to rinse impeller cavity.

*Whitehall recommends the use of Hydrochlor® Whirlpool Antiseptic with all patient treatments.

This simplifies cleaning of equipment by eliminating need for repeated rinsing and scrubbing.

Important

The following chemicals are NOT recommended:

Sodium or calcium hypochlorite, chlorines, or

bleach:

Chloride ions are a major cause of

stainless steel pitting and are highly caustic and

corrosive. If used, wear skin, eye and respiratory

protection. Immediately rinse off residue.

Phenolics:

Phenolics damage metal parts and

plastics and distort the water-lubricated hard-

rubber bearing in turbine.

DO NOT USE.

Glutaraldehydes

: These chemicals are good

disinfectants but poor cleaners. Exposure to

vapors is harmful.

DO NOT USE.

Iodines:

Iodines are good disinfectants but poor

cleaners. Iodines corrode metal surfaces

including stainless steel. If used wear respiratory

protection. Immediately rinse off residue.

Alcohol:

Alcohol-based cleaners have limited

effectiveness against some common

microorganisms. They are also extremely

flammable and corrosive. DO NOT USE.

Ÿ

Ÿ

Ÿ

Ÿ

Ÿ

Important

Using abrasive compounds or applicators can

damage the whirlpool's appearance. Do not use

abrasive materials to clean the whirlpool.

Cleaning and Disinfecting

28