INSTALLATION

Note: Greater back clearance will improve the ease of serviceability of the stove.

PAGE 16

INSTALLING YOUR FREESTANDING PELLET STOVE

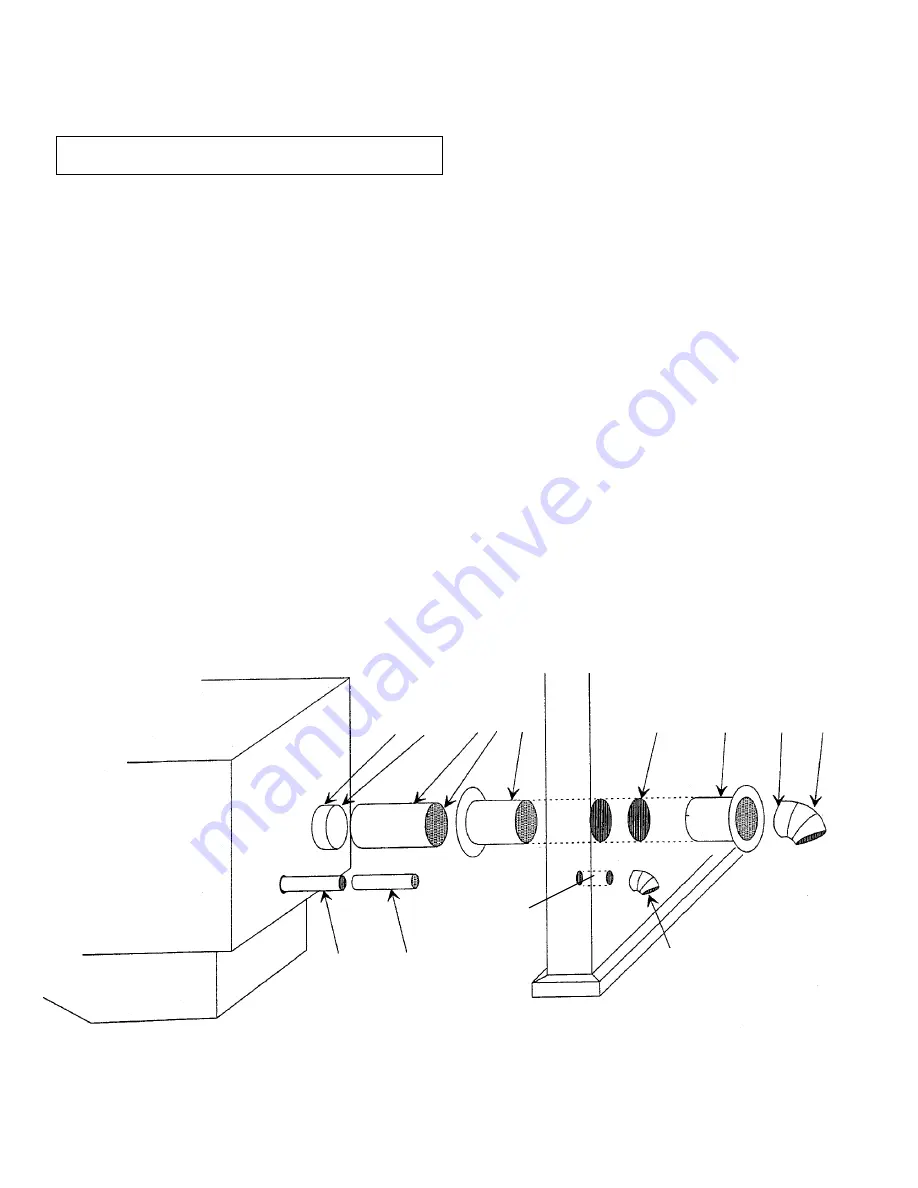

Standard Horizontal Vent Installation

All PL Venting Components must be listed to UL 641

or ULC S609

1. Locate the proper position for the listed type “PL” wall

thimble. Avoid cutting wall studs when installing your

pipe. Use a saber saw or keyhole saw to cut the

proper diameter hole through the wall to accommo-

date the wall thimble. Use extreme caution to avoid

cutting into power lines within the wall of the home.

The hole size will depend on the brand of pellet vent

that you are using. Install the wall thimble in the hole.

2. ALL INTERLOCKING PIPE CONNECTIONS WITH-IN

THE ROOM MUST BE SEALED WITH HIGH TEM-

PERATURE RTV AND SECURED WITH A MINIMUM

OF 3 FASTENERS PER CONNECTION. Position the

stove approximately 12” (305 mm) from the wall on

the floor pad. Push the “PL” pipe through the wall

thimble. Squeeze a bead of high temperature silicone

(RTV) sealer around the end of the machined portion

of the 3” (76mm) pipe connector on the back of the

stove. Firmly push on a section of “PL” pipe until in-

ner pipe liner pushes into the bead of RTV sealer.

3. Push the stove with pipe attached towards the wall

(the pipe will go through the wall thimble). Do not

position the back of the stove closer than 2” (51mm)

from the wall (see clearances, page 6). Note:

Greater back wall clearance will improve the ease of

serviceability of the stove.

4. Install listed type “PL” 45 degree elbow with optional

rodent screen or cap (recommended) on outside end

of pipe. The rodent screen should be no less than

1/2” (13 mm) mesh and may clog with soot and ash if

left unattended during the burn season.

NOTE: The end of the exhaust pipe must extend a

minimum of 12” (305 mm) from the outside of the

building.

5. If the installation includes a source of outside com-

bustion air; cut a separate hole through the wall for

the fresh air tube. Use a galvanized or stainless steel

pipe for the duct. The minimum size for the duct

shall be not less than 50% of the cross sectional flue

area. Connect outside air pipe to air inlet on stove.

This tube must be terminated with a 45 degree elbow

or hood.

NOTES:

Combustion air may also be drawn from a vented crawl

space under the home.

All joints for connector pipe are required to be fastened

with at least three screws. If vented horizontally, joints

shall be made gas-tight (air tight, sealed connection) in a

manner as specified on this page (see instruction #2).

Install vent at clearances specified by the vent manufac-

turer.

Inlet Air

Port

Metal

Fresh Air

Pipe

45 Degree Elbow Joint

For Fresh Air Pipe

Hole Through the Wall for the Thimble

Pipe Connector on Stove

Wall T

himble

Use RTV High Temp Silicone

Hole

Through

the Wall for

the Fresh

Air Pipe

Use RTV High

Temp Silicone

45

°

Elbow

Horizontal l Pipe Use RTV High T

emp Silicone

Wall T

himble

www.PelletKing.com

Summary of Contents for Advantage II-T C FS

Page 34: ...WIRING DIAGRAM PAGE 34 www PelletKing com ...

Page 44: ...ADVANTAGE II T C EPA LABEL COLORADO COMPLIANCE LABEL PAGE 44 www PelletKing com ...

Page 45: ...SIMPLE OPERATING INSTRUCTIONS LABEL PAGE 45 www PelletKing com ...

Page 46: ...INSTALLATION TIPS PAGE 46 www PelletKing com ...

Page 48: ...1110 West Taft Avenue Orange CA 92865 www PelletKing com ...