32

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE

Air Wash

To inhibit buildup of soot on the door glass, air

is delivered to the glass through an air wash

system located in the doorframe surrounding

the glass.

Auger

It transfers the fuel from the hopper to the feed

chute to deliver pellets to the UltraGrate™.

Auger Motor

Drives the Auger. Motor specifi cations are: .4

Amp, 1.1 RPM (revolutions per minute).

Blower, Room Air (Convection)

The blower function is to transfer the heat from

the appliance to heat the room air.

Blower, Exhaust (Draft Inducer/combustion)

It has a radial impeller to deliver more air to the

UltraGrate™. It pulls air into the UltraGrateby

creating a negative pressure. This is done by

extracting the exhaust gases out of the fi rebox

and pushing the exhaust downstream to the

fl ue exit.

Heat Select Button

This is the heat output control button. It controls

power to the feed system - auger motor and

exhaust blower. Use the heat select button to

adjust to any of the three feed rate settings

(which controls the burn rate).

Photoeye

The photoelectric eye that senses the fl ame, or

lack of. It is designed to signal the control board

to discontinue power to the auger motor if it

fl ame is not sensed in the UltraGrate.

Pressure Switch

A safety device used to shut off the feed system

(auger motor) if there is too much back pres-

sure in venting system. Some possible causes

are as follows:

• The venting system is obstructed.

• High altitude or other misc. environmental

conditions affecting exhaust fl ow.

• Improper venting system.

UltraGrate (Burn Grate)

This is where combustion occurs and may be

referred to as the “Burn Grate”.

Thermal Switch, High Limit (L250-30F, N/C)

There are 2 of these thermal switches on this

model. If a temperature reaches 250° F., the

high limit auto reset will “trip” and stop the fl ow

of electricity to the auger motor. The thermal

switches will not automatically reset until it has

cooled below 220° F).

Thermal Switch for Room Air Blower

– This

thermal switch is located on the room air

blower jacket and is designed to detect an

overfi re condition.

Thermal Switch for Combustion Air Inlet

– This thermal switch is located on the

combustion air inlet and is designed to

detect reversed fl ow. If negative pressure

in the dwelling (i.e. An extremely tight house

which may not supply adequate combustion

and ventilation air) causes the exhaust to

pull back from the combustion air inlet, the

heat from the exhaust will result in heat

activation of this thermal switch.

Door Switch

(Profi le

®

30 FS-2 and Profi le 30 INS-2)

If the door is opened during operation (on model

Profi le 30 FS-2 and Profi le 30 INS-2), this switch

disconnects power to the auger motor resulting

in the unit shutting down.

Hopper

The hopper is where the pellets are stored.

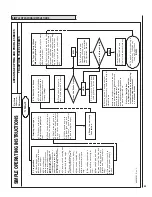

NOTE: Switch conditions given at

room temperature, Stove OFF

N/C = Normally Closed

Auger

Motor

16 8

9 1

(white)

(brown)

(black)

(black)

(blue)

(orange)

(brown)

(black)

(purple)

(purple)

(red)

(red)

NEUTRAL

GROUND

POWER (HOT)

IGNITER

POWER

DISCONNECT

PRESSURE SWITCH

N/C

JUMPER 1-3

JUMPER

6 AMP

120 V.

HIGH LIMIT SWITCH

L250-30F(N/C)

(INLET) HIGH LIMIT SWITCH

L250-30F(N/C)

JUMPER 2-4

2

1

4

3

Convection

Room Air

Blower

Exhaust

(combustion)

Blower

Photoeye

(yellow)

(yellow)

Thermostat

Connector

Figure 56 - WIRING DIAGRAM 120 V AC

* N/C = Normally Closed Switch

N/O = Normally Open Switch

COMPONENT DEFINITIONS