Kunststoffschweißtechnik

Operating

and

indicating elements

Chapter 4

07.02.13

Working Instructions WIDOS 25000 mobile

Page 21 of 116

No. Denomination

Function

10 Left and right pipe slide

- for sliding the pipes into / out of the clamping rings

- lifting is done via: mode select 1, lever 3 and 4

11 Pipe clamper

- attached to each clamping ring, are clamped / released

individually

- clamping is done via mode select 2, lever 2 - 4

12 Pressure gauge, digital

- showing the current welding pressure

13 Hydraulic aggregate

- for applying the welding pressure and clamping pressure

- for all hydraulic motions

14 Pipe cutter

- for cutting the pipe ends plane and parallel

15 Heating element

- for heating the pipe ends

16 Machine illumination

- right and left hand, is activated and deactivated by the

switch illumination in the switch cabinet

17 Right and left hydraulic

couplings

- quick-action couplings for the front and rear leveling legs,

free couplings e.g. for pipe brackets

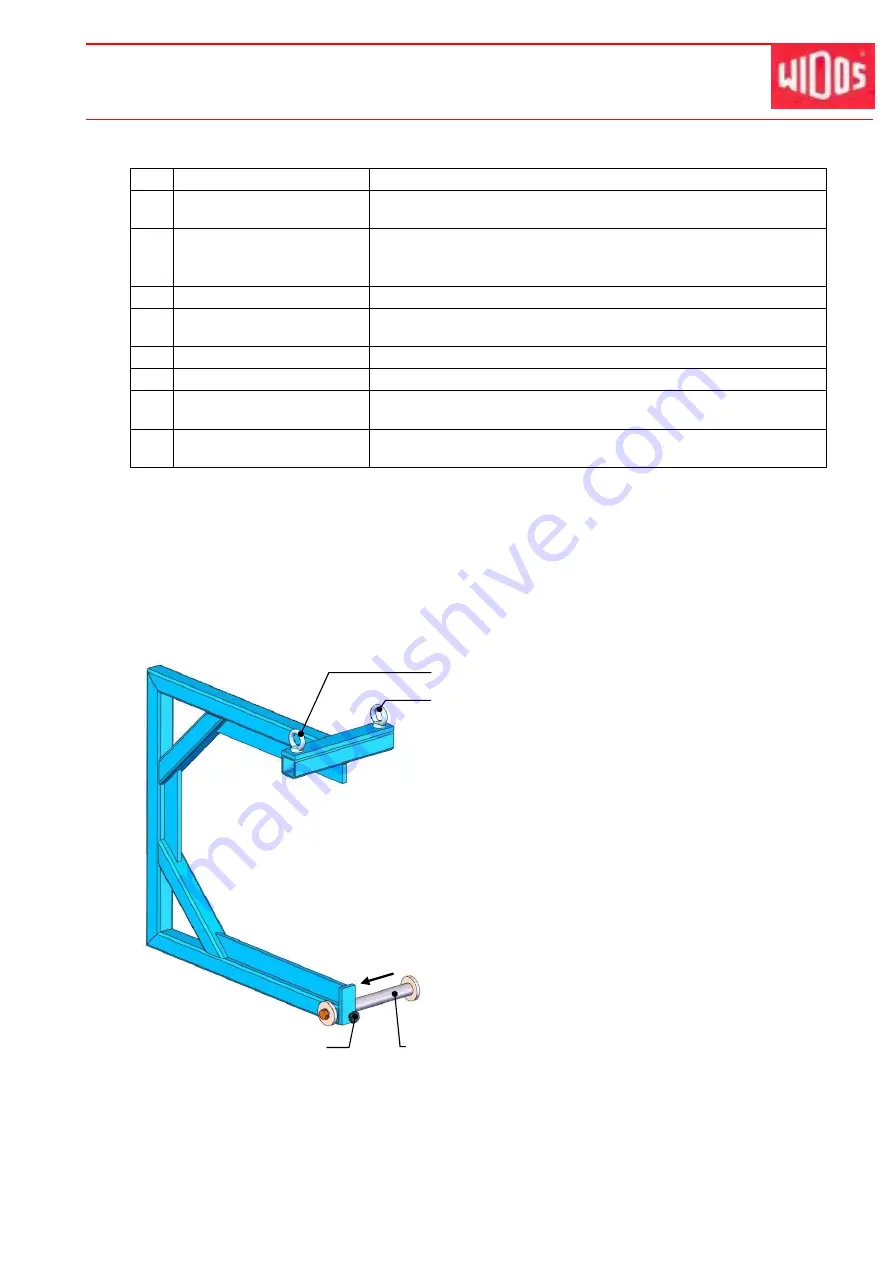

4.2.1. Reducer inserts and assembling aid (optional)

In order to install the reducer inserts, use the assembling aid. Lift the front reducer inserts at

the second drill hole from above and the rear reducer inserts at the third drill hole from above;

the clamping rings are hanging now in mounting position.

The reducer inserts are laterally guided on the clamping ring by lugs and are fixed within the

clamping ring by the bolt for reducer insert.

Assembling aid:

The assembling aid is used for all reducer inserts.

Suspend the reducer inserts for the right clamping

rings from the axis (mounted to the left side as

illustrated).

Then lift the assembling aid e.g. by a crane to ring

bolt 1 hinging the reducer insert vertically.

If you want to put the reducer inserts into the left

clamping rings, use ring bolt 2.

Detach the knurled screw and shift the axis in

arrow direction up to limit stop.

Fix the axis again by the knurled screw.

Ring bolt 1 for right clamping rings

Axis in position for right clamping rings

Knurled screw

Ring bolt 2 for left clamping rings