Ku nst sto ffschweißtec hni k

Equipment care / maintenance / repair

Chapter 7

02.08.2011

Working Instructions WIDOS 4900 CNC 3.5

Page 45 of 68

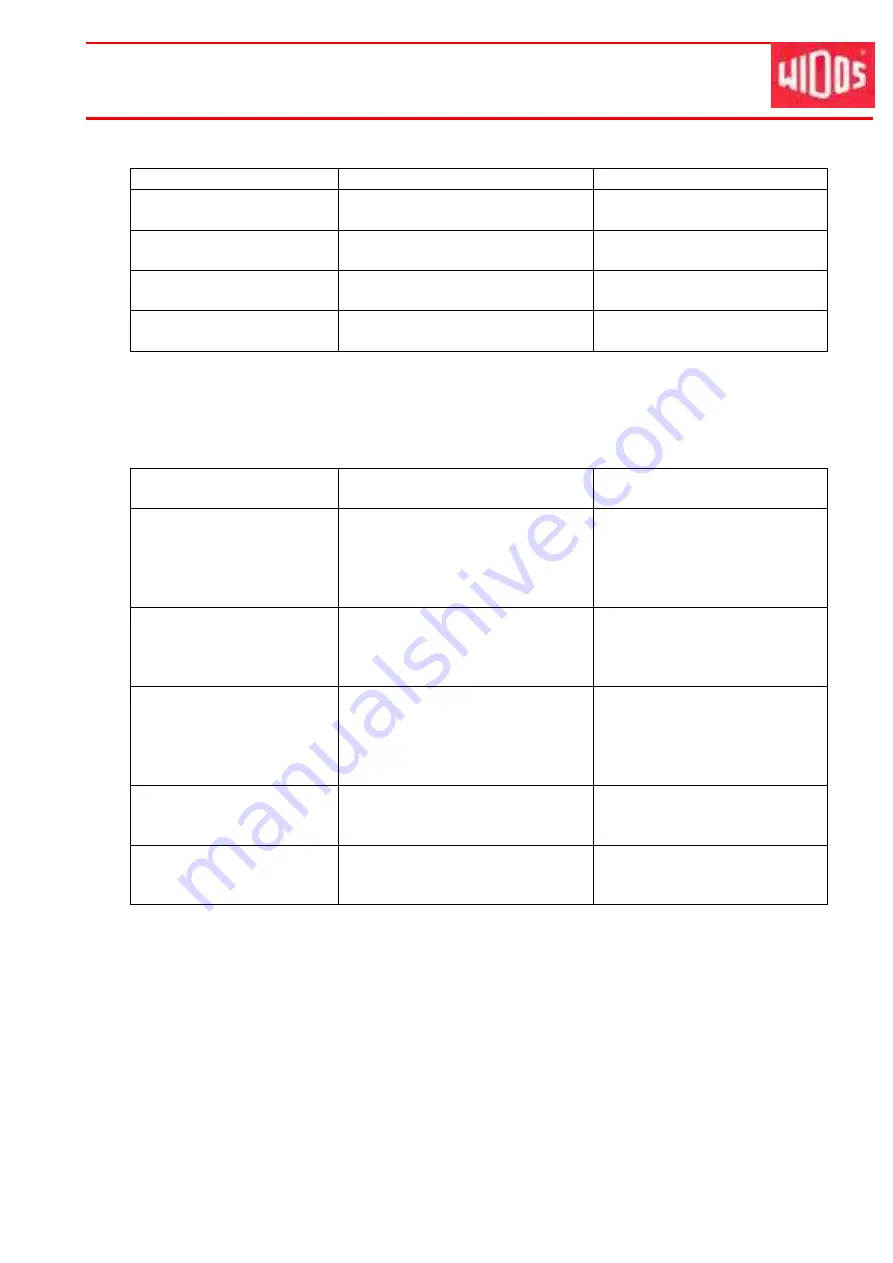

Error message

Cause

Remedial action

ambient.temp.

not o.k. !

Ambient temperature is higher

than 50° C or lower than 0° C

Use a welding tent or umbrella

or pre-heat pipe ends

error des. temp.

choose material !

No pipe parameters were set

Set pipe parameters

error: check cable

to way measuring !

Travel measuring cable is not

connected or defective

Connect or replace travel

measuring cable

error: pipes not

well in place !

In the pressureless phase, the

pipes open the clamping devices

Prevent the clamping devices

from opening

7.10. Possible defects and their elimination

Defect

Possible cause

Identification and

elimination

Machine does not move

forward nor backward

- Emergency-stop is pressed

- A valve is not getting its

command

- Travel cable is not plugged

- Travel cable is interrupted

- Unlock the Emergency-stop

- Start "Test and diagnosis

program".

- Perform diagnosis No. 0008

travel test

Planer works the whole

time or not at all

- Button at the planer is not

pressed

- Semi-conductive relais

defective

- Check the button.

- Perform diagnosis No. 0003

planer

After the planer program

the planer is needed again

and again

- No 2 mm material were planed

- The travel measurement varies

too much due to a defective

travel recorder or a

defective travel recorder cable.

- Make sure that min. 2 mm

material are being planed

(circular chip!).

Machine does not switch

from bead up programm to

"heating"

- No travel change is recognized - Perform diagnosis Nr. 0008

travel test

The pressure falls very

fast, the pump keeps on

working

- Pipes have slipped through

- Hydraulic bloc is leaky

- Cylinder is leaky

- Clamp pipes correctly.

- Check oil leakage.

- Inform service-team