K

u

n

st

st

o

ffs

c

h

w

e

iß

te

c

h

n

ik

W

e

ld

in

g

T

a

b

le

C

h

a

p

te

r 6

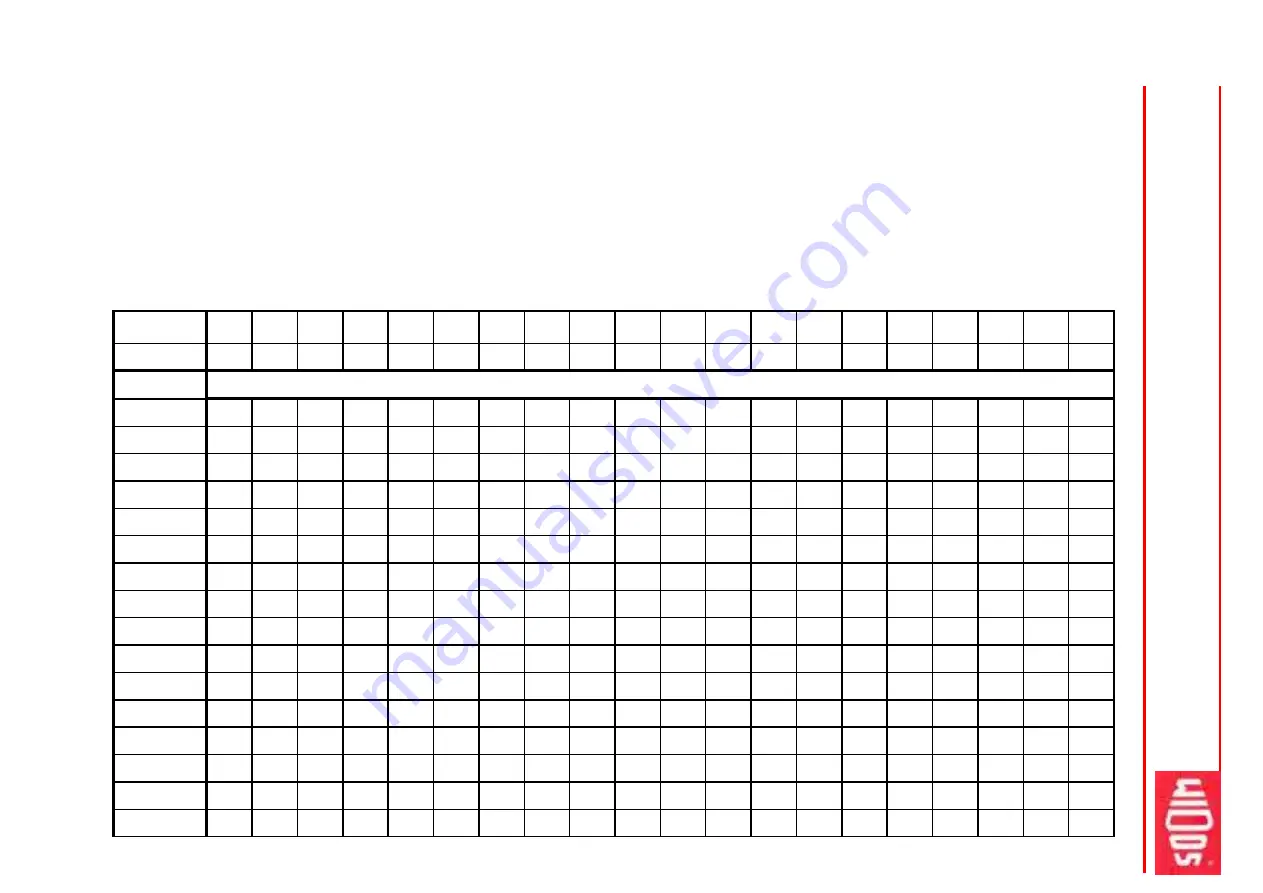

20

2

19

2

18

2

17

2

16

2

15

2

14

2

13

2

12

1,5

11

1,5

10

1,5

9

1,5

8

1,5

7

1,5

6

1

5

1

4

1

3

0,5

2

0,5

1

0,5

PE 80

PE 100

Tickness

Bead height

Lenght

J o i n i n g f o r c e

[kp]

For

smaller

wall thickness higher temperatures should be relized.

The standard value for the heating element temperature is 220° C.

The change-over and pressure building up time should be realized with PE 100 as fast as possible!

For the given adjusting and welding force the movement force of the welding slide has to be added! 1 kp = 10 N

Table for PE

Heating up time = 10 x wall thickness [sec]

Cooling down time under joining force = 1,333 * wall thickness [min]

The standard value for the heating element temperature is between 200° C - 220° C.

319

325

331

337

343

349

355

361

367

373

379

385

391

397

403

409

303

308

314

320

325

331

337

343

348

354

360

365

371

377

382

388

287

292

298

303

308

314

319

325

330

335

341

346

352

357

362

368

271

276

281

286

291

296

301

307

312

317

322

327

332

337

342

347

255

260

265

269

274

279

284

289

293

298

303

308

313

317

322

327

239

244

248

253

257

262

266

271

275

280

284

289

293

298

302

307

223

227

232

236

240

244

248

253

257

261

265

269

274

278

282

286

207

211

215

219

223

227

231

235

238

242

246

250

254

258

262

266

191

195

199

202

206

209

213

217

220

224

227

231

235

238

242

245

175

179

182

185

189

192

195

199

202

205

208

212

215

218

222

225

160

163

166

169

172

175

178

181

184

187

190

193

196

199

202

205

144

146

149

152

154

157

160

163

165

168

171

173

176

179

181

184

128

130

133

135

137

140

142

145

147

149

152

154

157

159

161

164

112

114

116

118

120

122

124

127

129

131

133

135

137

139

141

143

96

98

100

101

103

105

107

109

110

112

114

116

118

119

121

123

80

82

83

85

86

88

89

91

92

94

95

97

98

100

101

103

64

65

67

68

69

70

71

73

74

75

76

77

79

80

81

82

48

49

50

51

52

53

54

55

55

56

57

58

59

60

61

62

32

33

34

34

35

35

36

37

37

38

38

39

40

40

41

41

16

17

17

17

18

18

18

19

19

19

19

20

20

20

21

21

1060

1080

1100

1120

1140

1160

1180

1200

1220

1240

1260

1280

1300

1320

1340

1360

0

3

.0

3

.2

0

0

9

W

o

rk

in

g

In

s

tru

c

tio

n

s

W

ID

O

S

P

S

M

1

5

p

a

g

e

2

2

/ 4

o

f 3

3