K

u

n

st

st

o

ffs

c

h

w

e

iß

te

c

h

n

ik

W

e

ld

in

g

T

a

b

le

C

h

a

p

te

r 6

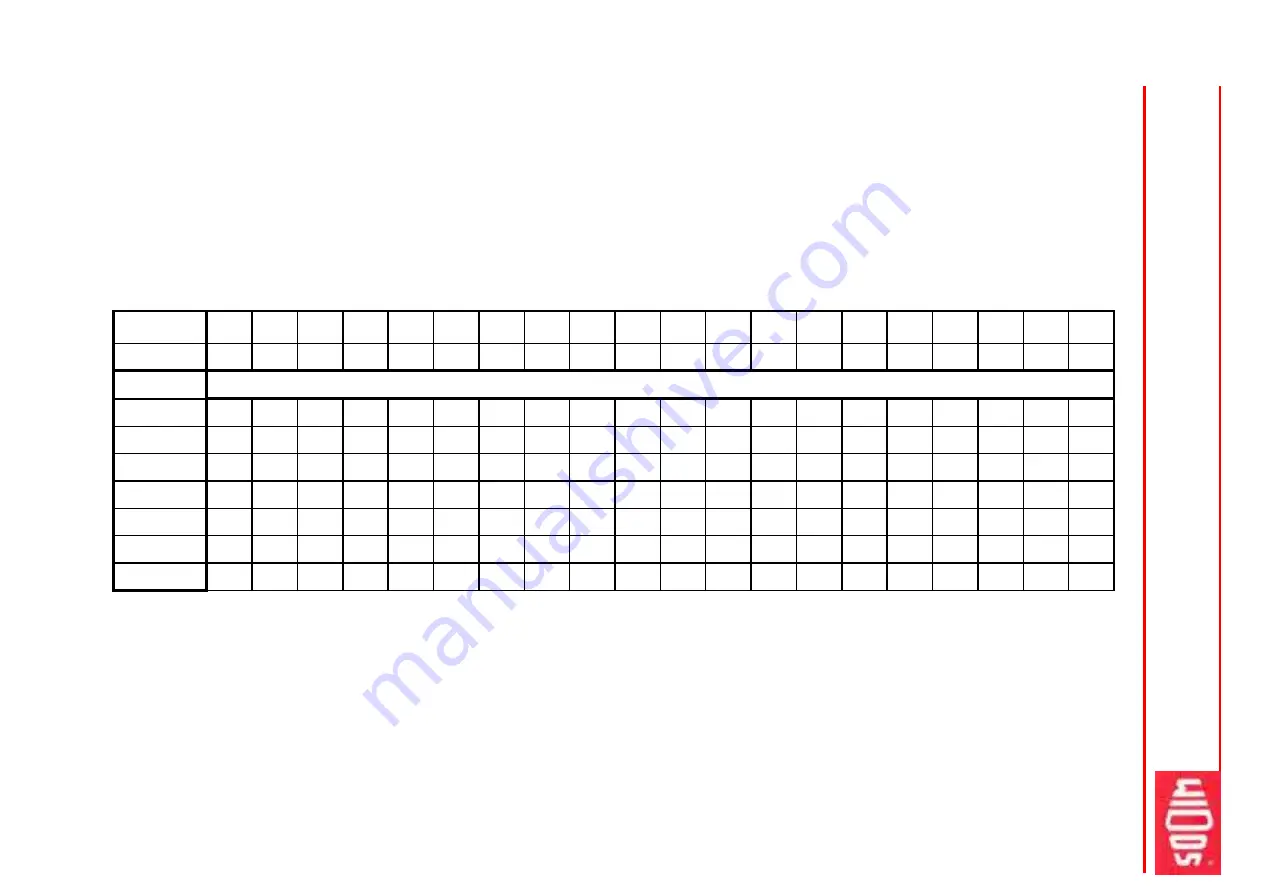

20

2

19

2

18

2

17

2

16

2

15

2

14

2

13

2

12

1,5

11

1,5

10

1,5

9

1,5

8

1,5

7

1,5

6

1

5

1

4

1

3

0,5

2

0,5

1

0,5

PE 80

PE 100

Tickness

Bead height

Lenght

J o i n i n g f o r c e

[kp]

For

smaller

wall thickness higher temperatures should be relized.

The standard value for the heating element temperature is 220° C.

The change-over and pressure building up time should be realized with PE 100 as fast as possible!

For the given adjusting and welding force the movement force of the welding slide has to be added! 1 kp = 10 N

Table for PE

Heating up time = 10 x wall thickness [sec]

Cooling down time under joining force = 1,333 * wall thickness [min]

The standard value for the heating element temperature is between 200° C - 220° C.

415

421

427

433

439

445

451

394

400

405

411

417

422

428

373

379

384

389

395

400

406

352

358

363

368

373

378

383

332

337

341

346

351

356

361

311

316

320

325

329

334

338

290

295

299

303

307

311

316

270

274

277

281

285

289

293

249

253

256

260

263

267

271

228

232

235

238

241

245

248

208

211

214

217

220

223

226

187

190

192

195

198

200

203

166

169

171

173

176

178

181

145

148

150

152

154

156

158

125

127

128

130

132

134

136

104

106

107

109

110

112

113

83

85

86

87

88

89

91

63

64

64

65

66

67

68

42

43

43

44

44

45

46

21

22

22

22

22

23

23

1380

1400

1420

1440

1460

1480

1500

0

3

.0

3

.2

0

0

9

W

o

rk

in

g

In

s

tru

c

tio

n

s

W

ID

O

S

P

S

M

1

5

p

a

g

e

2

2

/ 5

o

f 3

3